More information about the sound decoder can be found here

GB GB

14 3

Maintenance of the modelStarting locomotive operation

Unwrap model: Take out the model cautiously

ith foil (g. ).

Operating instructions: Before use is advisab-

le to let the loco go around about 30 minutes for-

ards an 0 minutes backards ithout load, to

obtain an optomal circuit and best tractive power.

The smallest radius this model should run is R2 of

the ROCO track system (R2 = 358 mm).

Your locomotive will run smoothly on clean tracks

only. For this purpose we recommend using item

no. 46400, Roco track cleaning van, or item

no. 10002, Roco track cleaning rubber, for

removing heavy dirt.

Fittings: Operation is possible with different

couplings (g. 2). e recommend using the oco

close coupling.

n the enclosed accessory bag you ill nd small

kits to be tted on your locomotive. lease mount

them cautiously.

Attention! se glue only if indicated (g. 2).

Running in digital mode:

Remove the jumper from the interface.

Finally put the plug of the chip into the interface

as shon in g. .

A.C. operation: see g.

To enoy your model for a long time, it is neces-

ary to service it regulary (i.e. after it has been in

ope-ration for approximately 30 hours).

1. Cleaning of wheel contacts: Wheel cont-

acts easily get dirty on tracks which are not en-

tirely clean. Use a small brush to remove dirt

from spots marked in g. . rior to cleaning the

contacts dismantle the bogie (g. ).

2. Lubrication: Apply tiny oil drops to spots

marked in g. . rior to lubrication dismantle lo-

comotive (g. 4). e recommend using item no.

10906, Roco oiler. For lubrication the gearparts

(e.g. cogheels, orm) e hould recommended

our Roco special grease (item no. 10905).

Attention: Please do not oil these parts when

using our grease.

3. Change of traction tyre: Remove the gear

cover (g. ). Take out wheel set and remove

traction tyre using a pin or a ne scredriver

(g. ). hen pressing on the ne traction tyre

please avoid twisting it.

4. Motor Changing: irst remove loco body (g.

4) and then change the motor (g. 0).

Assembly: During assembly please take care of

correct position of contacts.

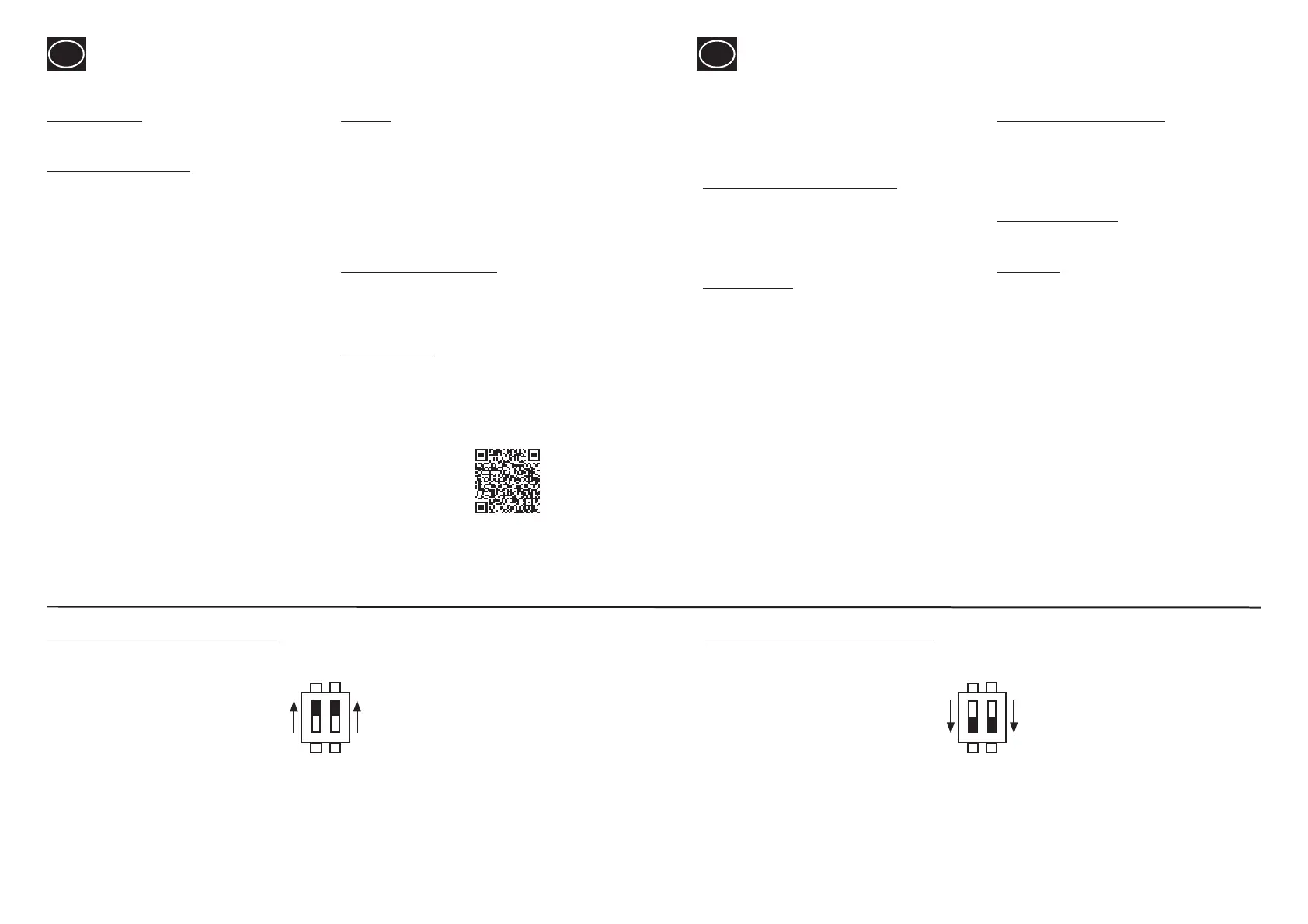

Position "ON"

Works setting: The headlight is illuminated in the analog and digital operations, depending on the direc-

tion of travel.

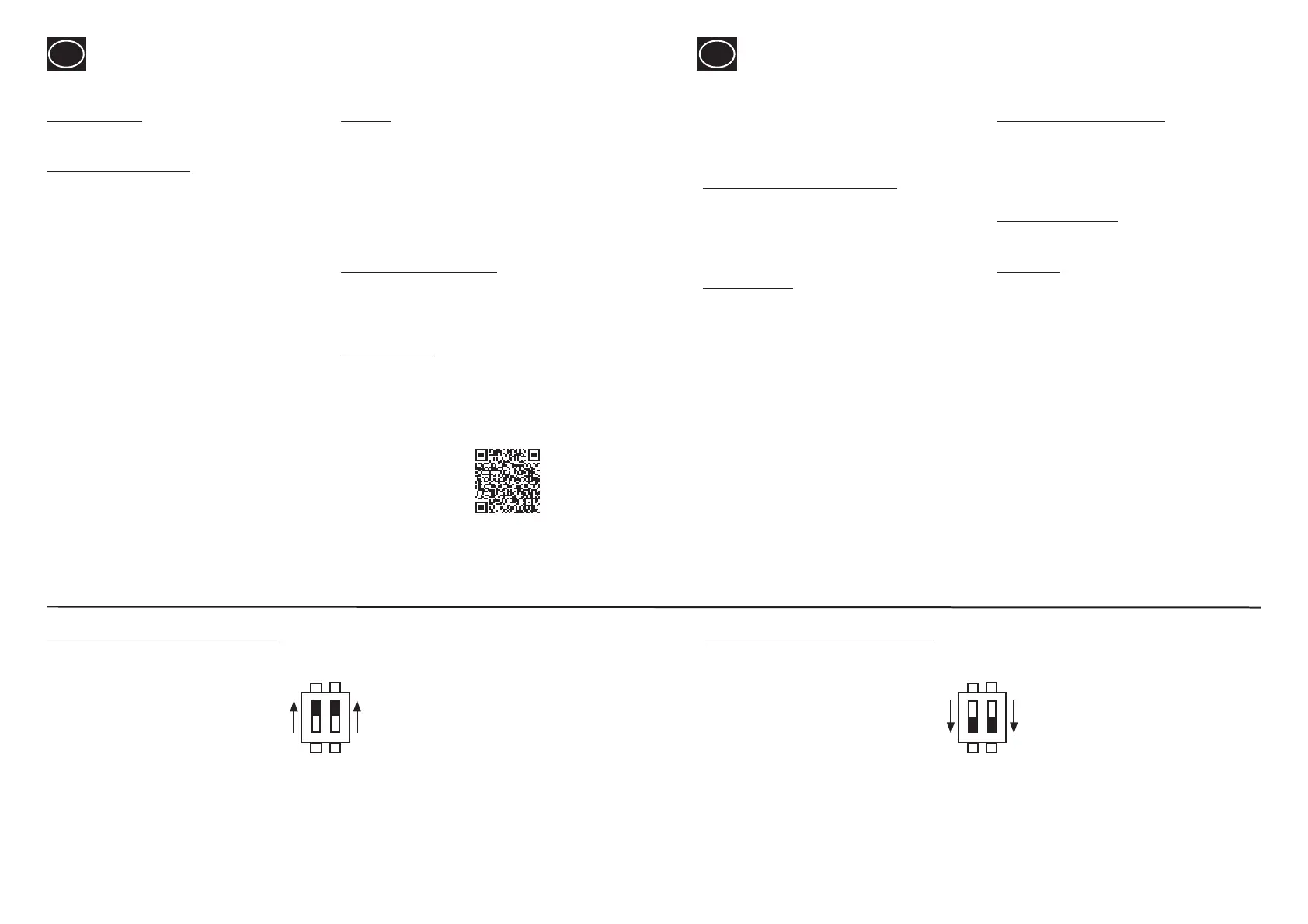

Position „OFF“

In the analog operation, the headlight is deactivated.

ON

1 2

Drivers Cab 1 ON Drivers Cab 2 ON

ON

1 2

Drivers Cab 1 OFF Drivers Cab 2 OFF

Dip-Switch for analog model 73216 Dip-Switch for analog model 73216

Loading...

Loading...