14. LINE VOLTAGE COMPENSATION

Fluctuations in the line voltage can cause a feeder bowl

to vary its feed rate. The line voltage compensation

feature adjusts the control's output to help compensate

for fluctuations in the supply voltage. If it becomes

necessary to disable this feature, the LV Comp setting

can be changed to “Disable”. It is found under “Power

Settings” menu.

15. LIMITING THE MAXIMUM

OUTPUT OF CONTROL

The maximum power (Max Pwr) setting can be lowered

to keep the operators from setting a higher than desired

feeder vibration. The maximum power setting can be

found under the “Power Settings” menu. It can be

adjusted from 100.0% down to 40.0%.

16. POWER SETTING

The output power is controlled by the UP and DOWN

arrow keys. The power setting can be adjusted unless

the security feature lock has been selected. Once the

proper security code has been entered, the power may

be adjusted under the “Power Settings” menu. Note:

the power setting may not be adjusted above the

maximum power setting or below the minimum power

setting level. The max and min power settings

automatically change the power setting to keep it in the

correct range.

17. SETTING THE MINIMUM

OUTPUT OF CONTROL

The minimum power (Min Pwr) output level can be

adjusted to the desired low level of vibration. The

minimum power setting can be found under the “Power”

menu. It can be adjusted up from 0.0% to 60.0%.

Note: the software does not allow the minimum level to

be within 6.4 counts of the maximum level.

18. SETTING THE TIME DELAYS

The ON and OFF sensor time delays are set

independently for a period of 0-25 seconds. The time

delay settings can be adjusted to provide the best

individual response for the feeder. The time delays can

be found under the “Timer Settings” menu.

19. DIAGNOSTICS

A. The first menu item under the “Diagnose Info” menu

shows the software revision level.

B. The next item under the software revision level

shows certain software registers that may be helpful

to Rodix staff while troubleshooting over the phone.

20. SECURITY SETTINGS

The “Security Settings” menu controls access to the

control settings. When enabled, a security code

number may be chosen from 00 to 255. The preset

code is 00.

A. The “Unlock” setting allows menu access for all

control adjustments and features.

B. The amplitude only (Amp Adj) adjustment allows

operators to adjust the amplitude through the

normal operating display. All other settings can

only be adjusted after entering the security code.

C. The “Lock” setting locks the control from any

adjustment without the use of the security code.

If the security code has been forgotten, press the

enter key to bring up the security code. Next, push

and hold the back key until the menu appears. This

sequence bypasses the security code.

21. DEFAULT MEMORY

Occasionally it is helpful to get back to a known

setting. Once a feed system has been set up properly,

it can be saved into the “user default” memory. If an

operator makes wrong adjustments, the “Restore

User” feature can restore the control to a known good

set up. The restore factory defaults selection will put

the original factory settings into memory.

22. LANGUAGE

The programming menus can be displayed in English,

French, German (Deutz), and Spanish (Espanol).

23. INSTALLING THE CFR SENSOR

Note: Failure to adequately prepare the feeder’s

surface properly may result in a Constant Feed Rate

(CFR) sensor that will not bond to the feeder. The

sensor will not be mounted until step C-6.

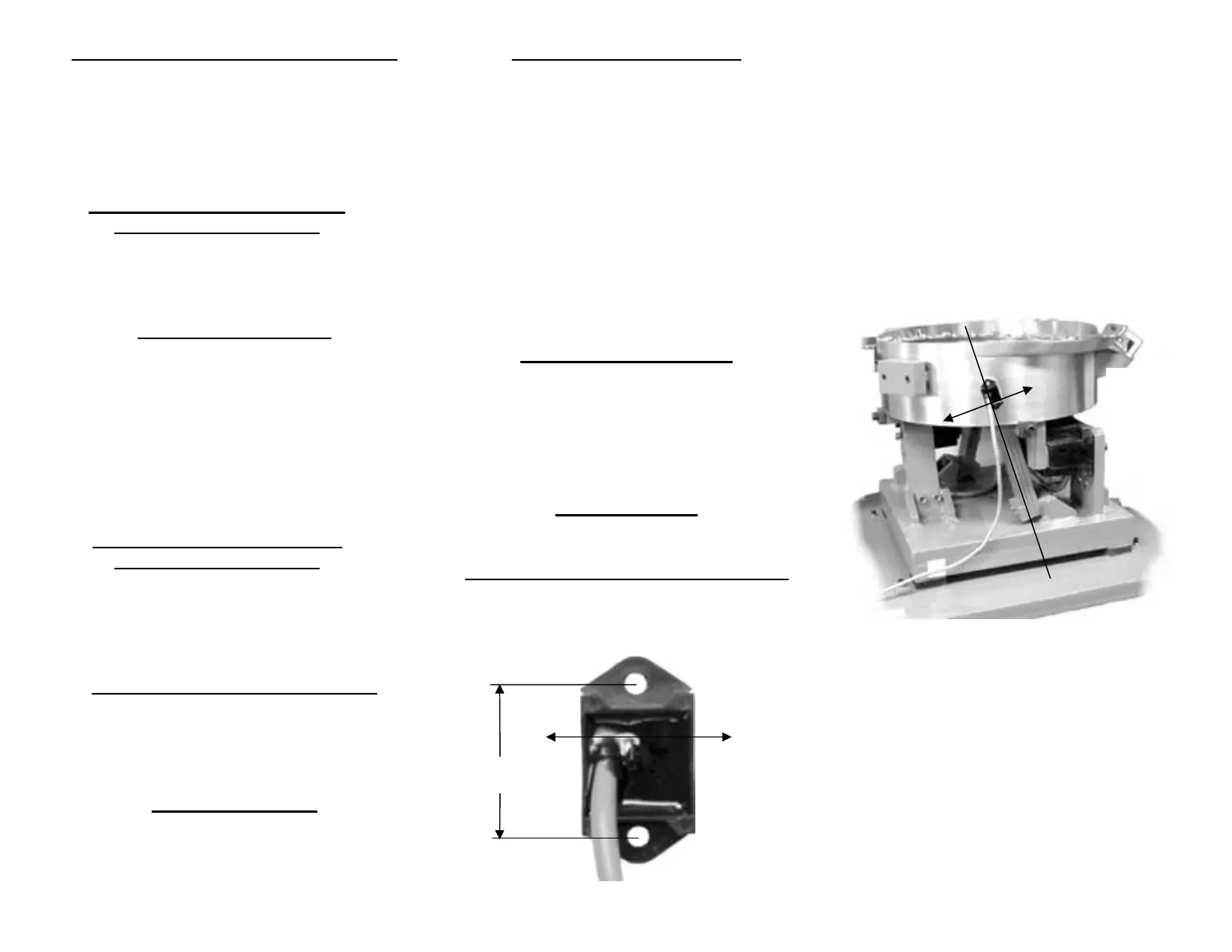

A. ORIENT THE SENSOR so that its sensitive

axis is in the same direction as the vibration of

the feeder. The double-ended arrow in figure 1

shows the sensor’s sensitive axis. Align the

sensitive axis of the sensor in the same direction

as the vibration (see figure 2). The sensor must

be oriented correctly for proper operation.

B. CHOOSE A LOCATION for mounting the

sensor on the feeder that is smooth and that will

allow the adhesive on the sensor to bond. Avoid

mounting the sensor over ridges and bumps which

can reduce the ability of the adhesive to stick to

the feeder. The correct location will also have

enough space for the sensor’s cable to hang

straight down without touching anything else.

Fig. 2 The arrow shows the direction of vibration

which is at a right angle to the spring pack.

C. SURFACE PREPARATION of the feeder is

crucial for proper bonding between the sensor and

the feeder. Please follow these steps completely.

1) The feeder should be kept between 70°-

100°F (21-38°C) for ideal tape application.

2) Clean a 3.5” (10cm) circular area with a

solvent like isopropyl alcohol that will not

leave a residue. As a rule of thumb, the

area can be considered clean when after

cleaning the area with a solvent-saturated,

white paper-towel, the towel is as clean as it

was before wiping.

FC-200-2.doc 10/22/2009 Page 3

Sensitive

Axis of

Vibration

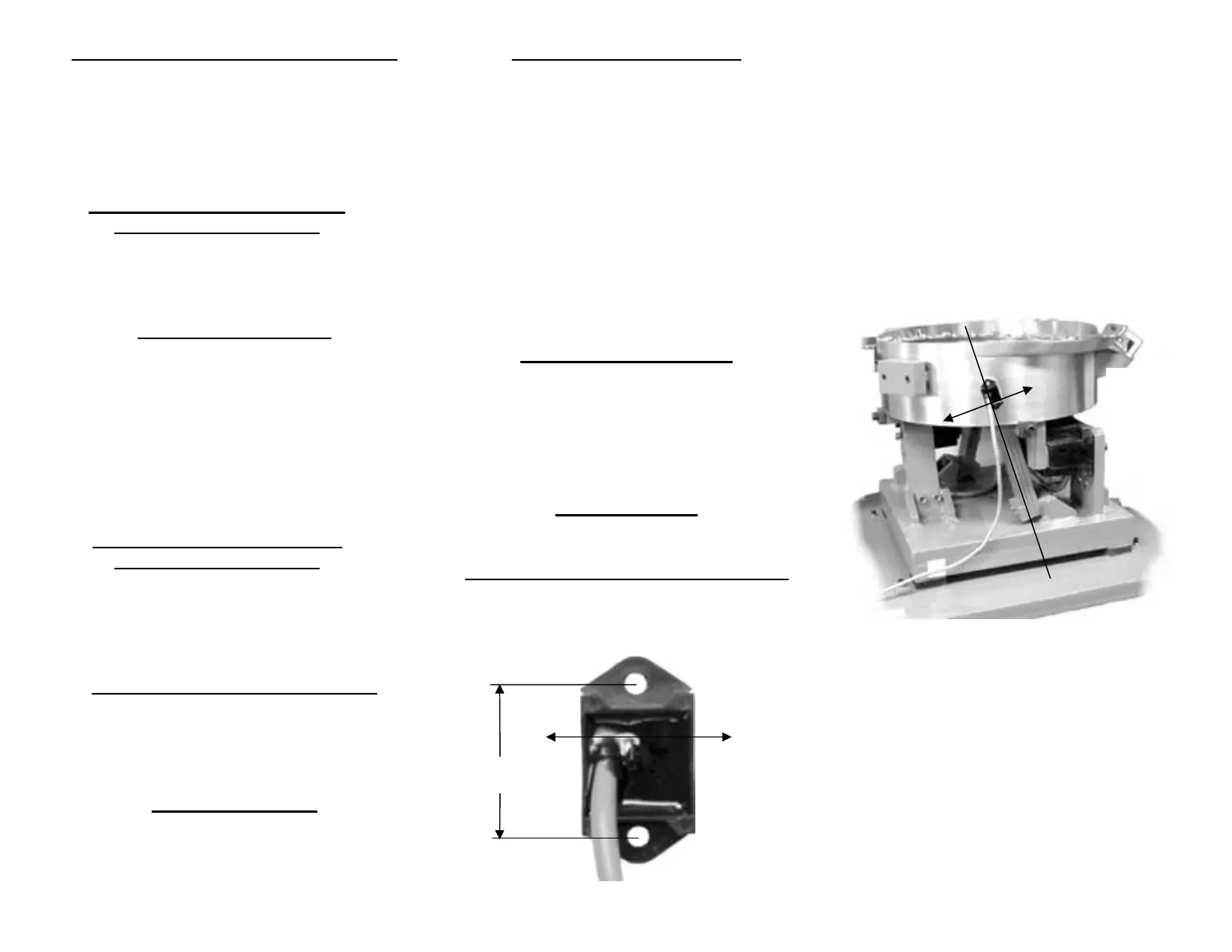

Fig. 1

Actual Size

1.375

Sensitive

Axis of

Vibration

Loading...

Loading...