Section 03 787 RFI ENGINE

Subsection 04 (BOTTOM END)

F12R18A

Do not apply in excess as it will spread out inside

crankcase.

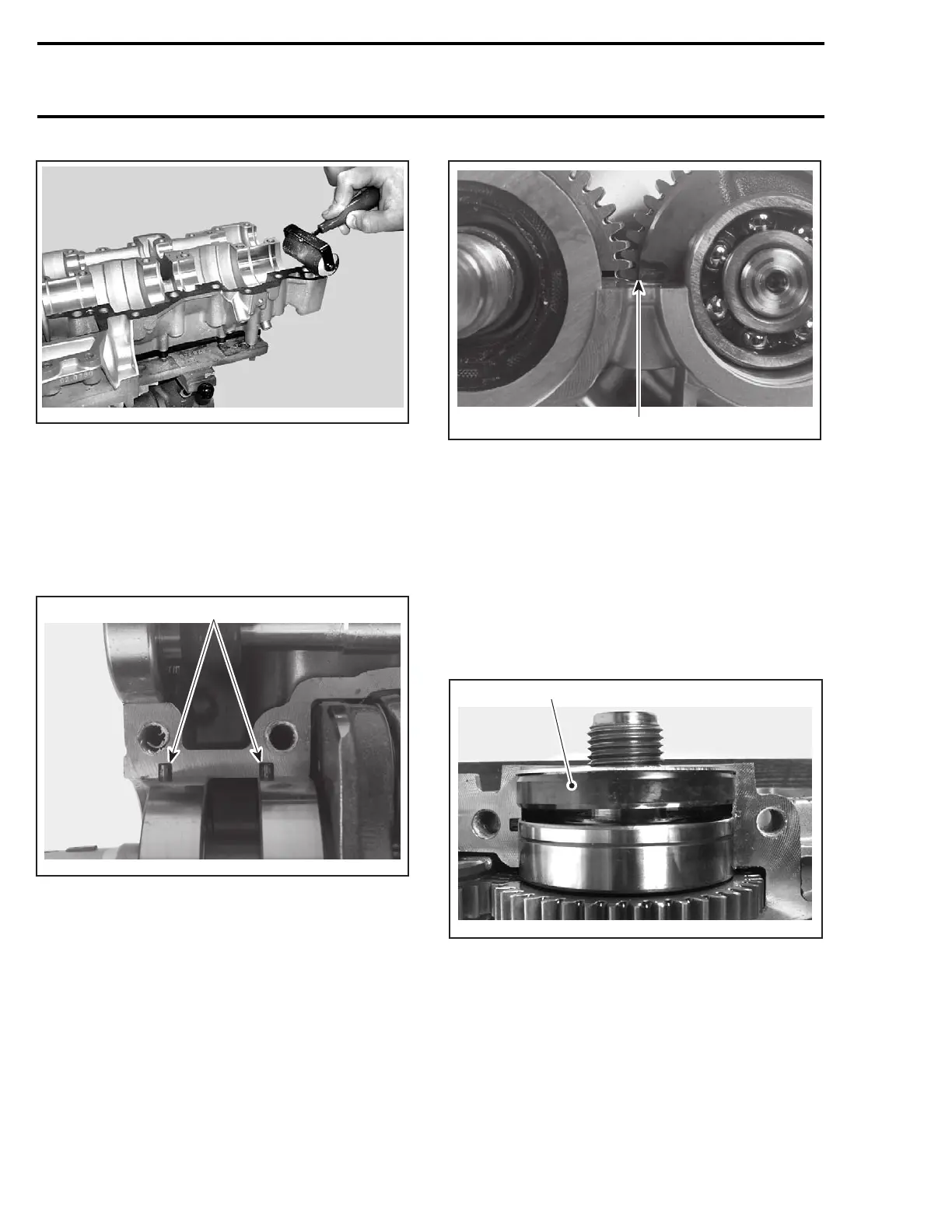

Crankshaft and Counterbalance Shaft

Install crankshaft no. 3 in crankcase.

NOTE: When installing crankshaft in crankcase,

make sure drive pins no. 6 of bearings are properly

installed in crankcase recesses.

F00D0OA

1

1. Drive pins

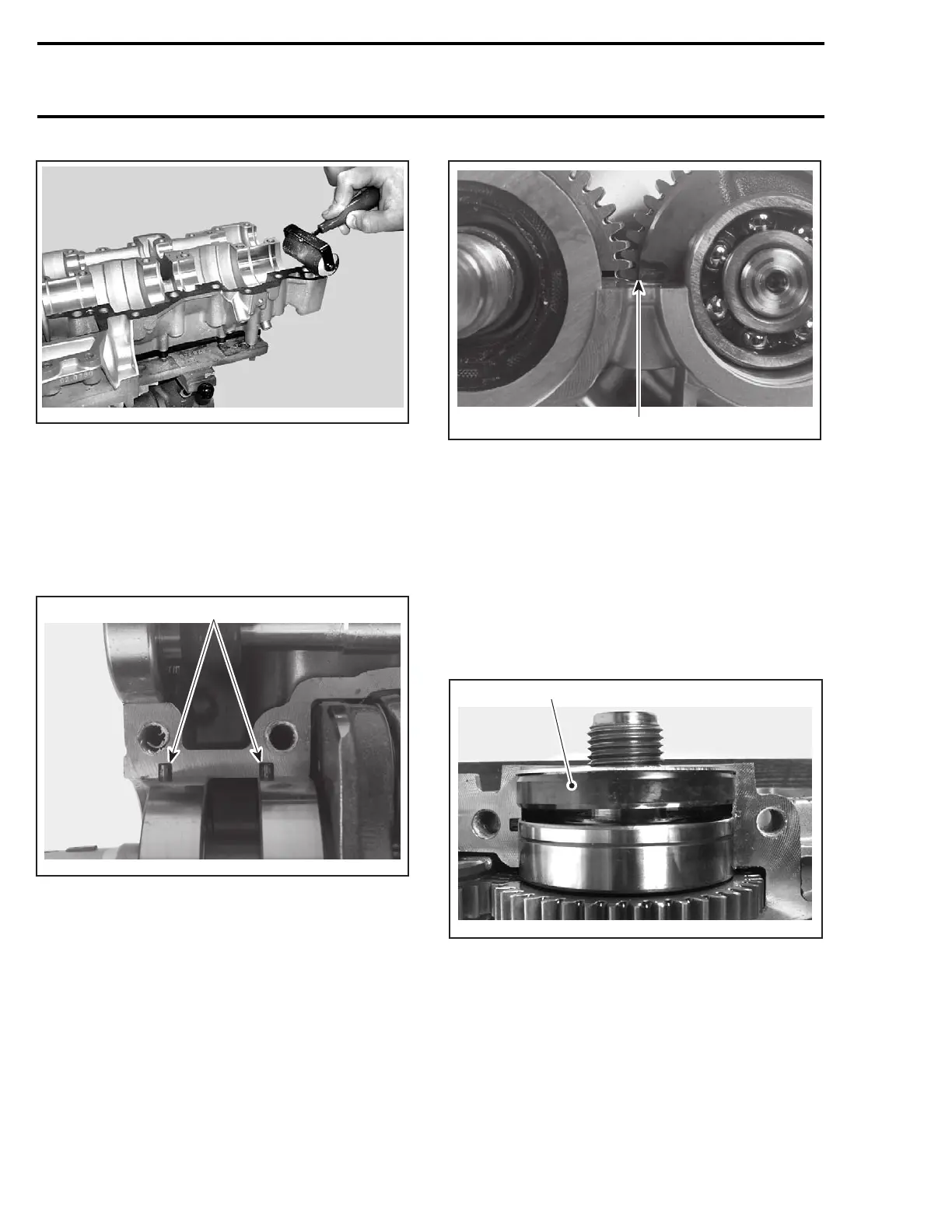

After crankshaft installation, install counterbal-

ance shaft no. 13. Make sure to properly index

crankshaft and counterbalance shaft by gear align-

ing marks.

CAUTION: Marks on the crankshaft and coun-

terbalance shaft must be aligned, otherwise en-

gine will vibrate and premature wear will occur.

F00D0PA

1

1. Marks must be aligned

Turn by hand the crankshaft and counterbalance

shaft. Make sure they do not interfere with the

crankcase.

PTO Crankshaft Seal

When installing seal no. 5, apply a light coat of

lithium grease on seal lips.

Position PTO seal against the retaining shim; the

gap between the seal no. 5 and bearing no. 4 will

ensure proper lubrication of the bearing.

F00D0NA

1

1. Seal against the retaining shim

Counterbalance Shaft Bearing Cover

Install the bearing cover no. 19 with its hollow side

toward the bearing.

98 smr2005-083

Loading...

Loading...