Section 01 ENGINE MEASUREMENT

Subsection 01 (MEASUREMENT PROCEDURES)

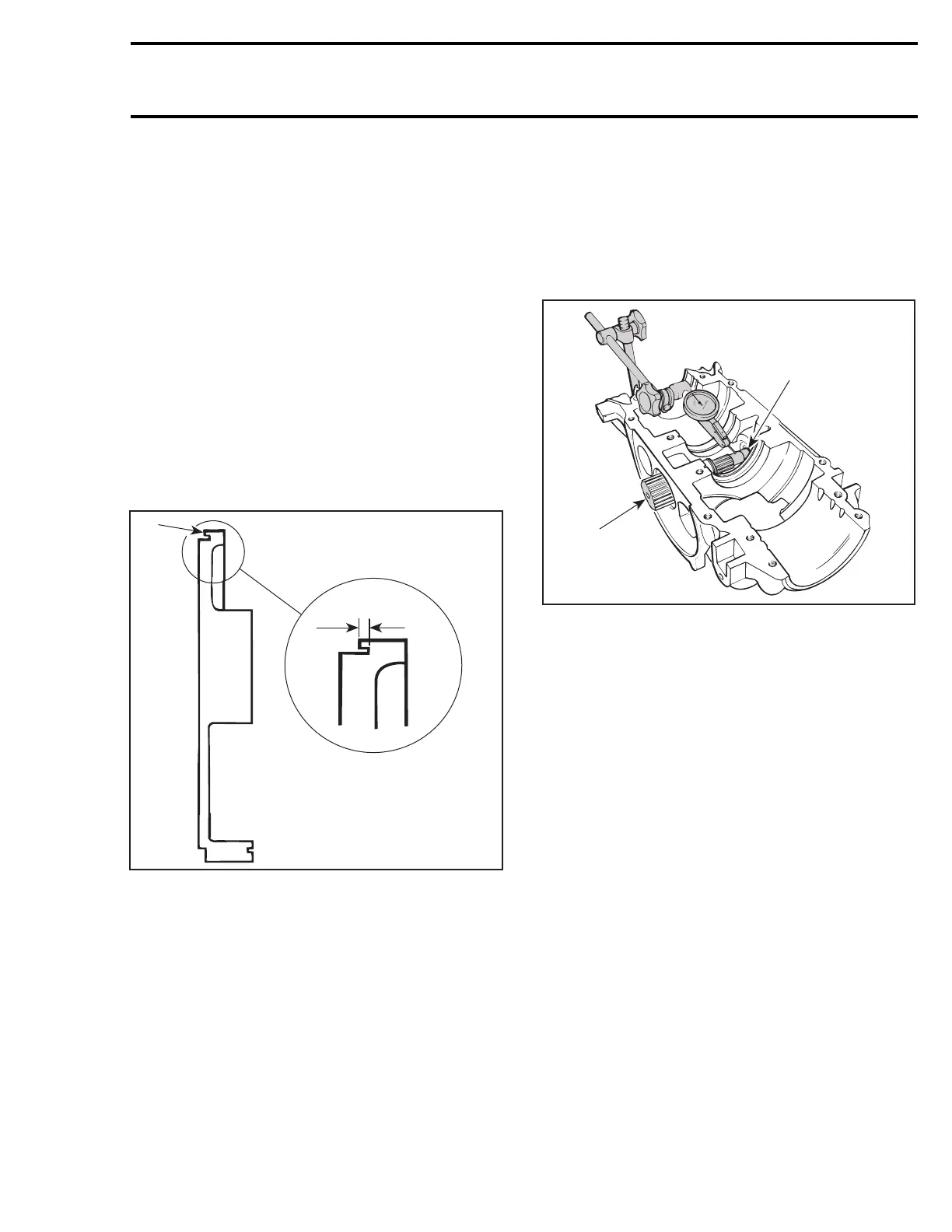

Remove cover then clean and measure com-

pressed soldering wire thickness, it must be

within the specified tolerance.

If rotary valve cover clearance is over specified tol-

erances, machine rotary valve cover seating sur-

face or replace the cover.

Machining the Rotary Valve Cover

The amount of material over tolerance must be

removed from the rotary valve cover seating sur-

face.

Also cut the O-ring groove the same amount to

keep the 1.00 ± 0.03 mm (.039 ± .001 in) depth

between the bottom of the groove and the seating

surface.

Remove burrs on the edges of the seating surface

andO-ringgroove.

1

A

F01D3OA

SAME AMOUNT REMOVED FROM COVER SEATING

SURFACE AND O-RING GROOVE BASE

1. Cover seating surface

A. O-ring groove depth must be 1.00 ± 0.03 mm (.039 ± .001 in)

Reverify the clearance.

At assembly, the rotary valve timing must remain

as per original setting.

NOTE: If rotary valve crankcase surface is worn, it

is possible to have it reworked at the factory.

Rotary Valve Shaft Deflection

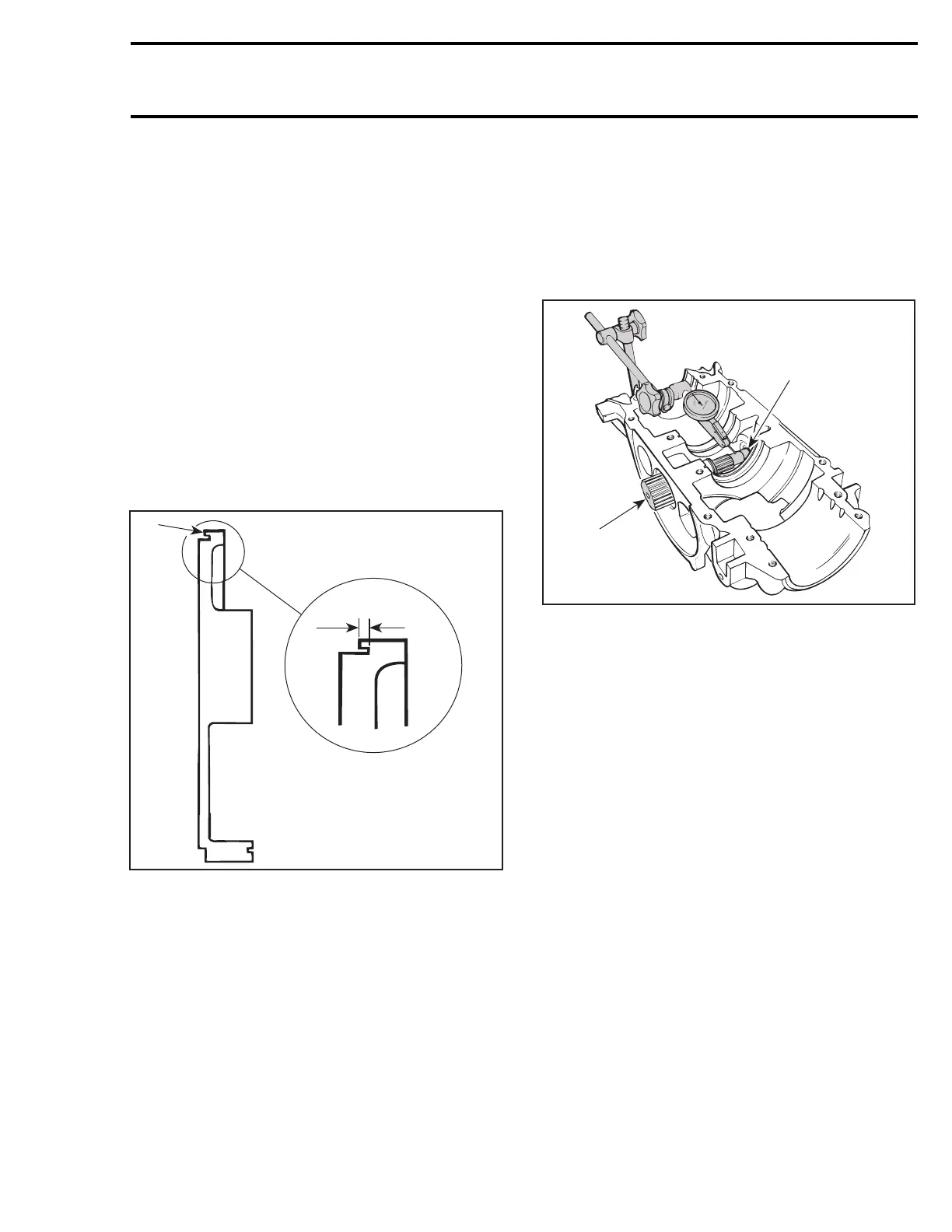

Deflection is measured with a dial gauge. Install

rotary valve shaft in crankcase half, without its

gear.

NOTE: End bearing must be in crankcase half.

Measure shaft deflection next to gear splines.

F01D2CA

2

1

1. Rotary valve shaft

2. End bearing in place

If the deflection of rotary valve shaft exceeds the

specified tolerance, replace it.

smr2005-085 9

Loading...

Loading...