RotorWay International

Exec 162F Construction Manual

Section 1

Page 5

Rev. 1 1/01

8. WORKING WITH PLASTIC FILLER (Bondo)

Before plastic body filler is applied to any surface, the surface must be sanded lightly and cleaned with acetone. Cream

hardener is added to activate the filler. Mix only a small amount that can be used within 3-4 minutes. Knead the tube of

cream hardener thoroughly before using. Dispense the desired amount of filler on a clean flat non-porous surface such as

metal or plastic. Use 1/4 teaspoon hardener to 4 tablespoons (2-1/2 oz.) filler or 2-1/2 grams hardener for 100 grams filler.

Mix with firm pressure using a back and forth wiping motion. Mix with a plastic spreader or putty knife to a uniform color at

room temperature. Apply thin to the surface, avoid using too much at a time. It is easy to mix another batch and apply more

material but the sanding process is time consuming. The surface should be dry and tack-free within 20-25 minutes. The

fastest method of finishing is to cut the Bondo off with a “cheese grater” file as soon as it becomes firm. Finish to final

configuration by hand sanding.

9. PAINTING AND FINISHING

We recommend that you talk to a local aircraft painter or paint supplier to find out what preparation and materials give best

results in your climate. For instance, in some areas near the ocean, zinc chromate primer is required to protect the

aluminum from salt air. If you do not have much experience spraying paint, you may prefer to have a paint shop do the

work for you. Our general recommendations are as follows:

Body, tail boom and main rotor blades: primer as required, 2 part Polyurethane paint.

Airframe and landing gear: sandblast with fine grit sand, 2 part epoxy paint.

10. PLATING AND ANODIZING

Contact RotorWay for recommendation of items that you want to plate or anodize. For example, a high stress item cannot

be plated. Have the plating done ONLY by a company qualified to plate aircraft parts.

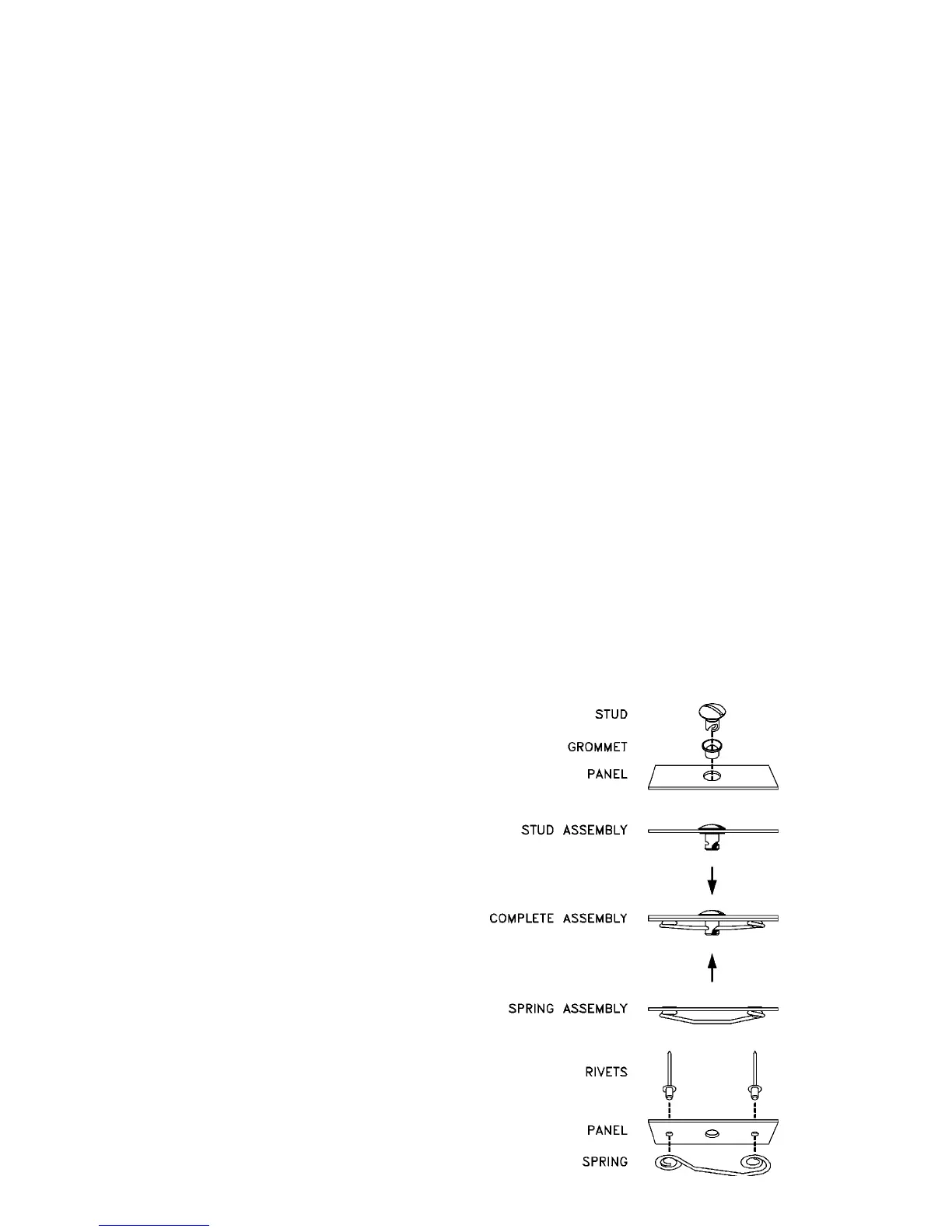

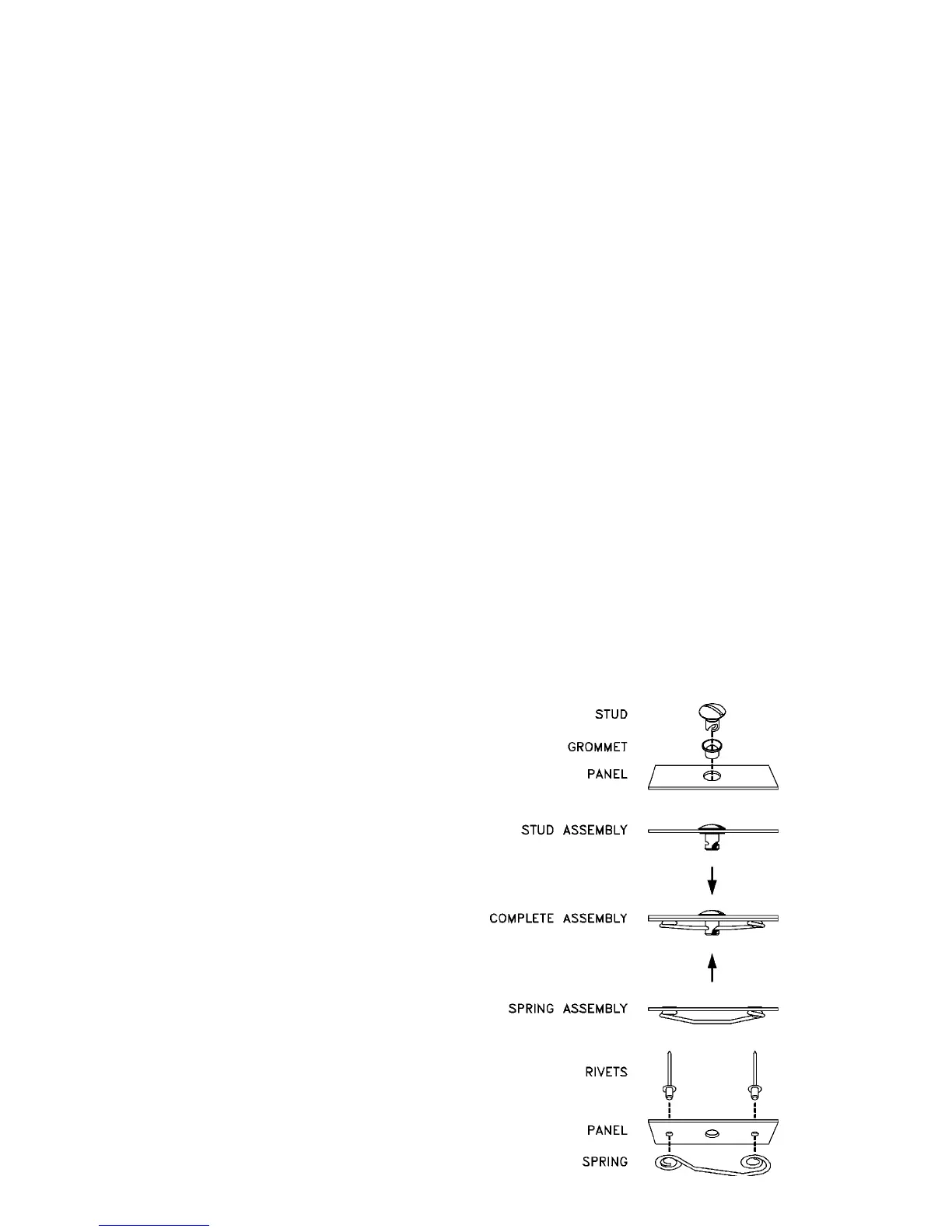

11. DZUS FASTENERS AND NUT PLATES

Dzus fasteners, commonly called “Dzus buttons”, are

composed of a stud, grommet and spring. The studs and

springs are made of steel, cadmium plated to prevent

corrosion. The grommet is made from aluminum alloy and

holds the stud in place on the panel. The Dzus fastener

locks with only 1/4 turn clockwise, and unlocks

counterclockwise.

Loading...

Loading...