the engine is still at normal operating

temperature, just after a run; warm oil and

sludge will flow out more easily. Park the

vehicle on firm, level ground, apply the

handbrake, then select 1st or reverse gear

(manual transmission) or the “P” position

(automatics). Open the bonnet and remove

the engine oil filler cap from the valve cover,

then remove the oil level dipstick.

6 Raise the front of the vehicle, and support it

securely on axle stands. Remove the front

right-hand roadwheel, then remove the plastic

panel under the wheelarch to provide

additional access to the oil filter.

Warning: To avoid personal

injury, never get beneath the

vehicle when it is supported by

only by a jack. The jack provided

with your vehicle is designed solely for

raising the vehicle to remove and refit the

roadwheels. Always use axle stands to

support the vehicle when it becomes

necessary to place your body underneath

the vehicle.

7 Being careful not to touch the hot exhaust

components, place the drain pan under the

drain plug, and unscrew the plug. If possible,

try to keep the plug pressed into the sump

while unscrewing it by hand the last couple of

turns. As the plug releases from the threads,

move it away sharply, so the stream of oil

issuing from the sump runs into the pan, not

up your sleeve! Allow the oil to drain into the

drain pan, and check the condition of the

plug’s sealing washer; renew it if worn or

damaged.

8 Allow some time for the old oil to drain,

noting that it may be necessary to reposition

the pan as the oil flow slows to a trickle. When

the oil has completely drained, wipe clean the

drain plug and its threads in the sump and

refit the plug, tightening it securely.

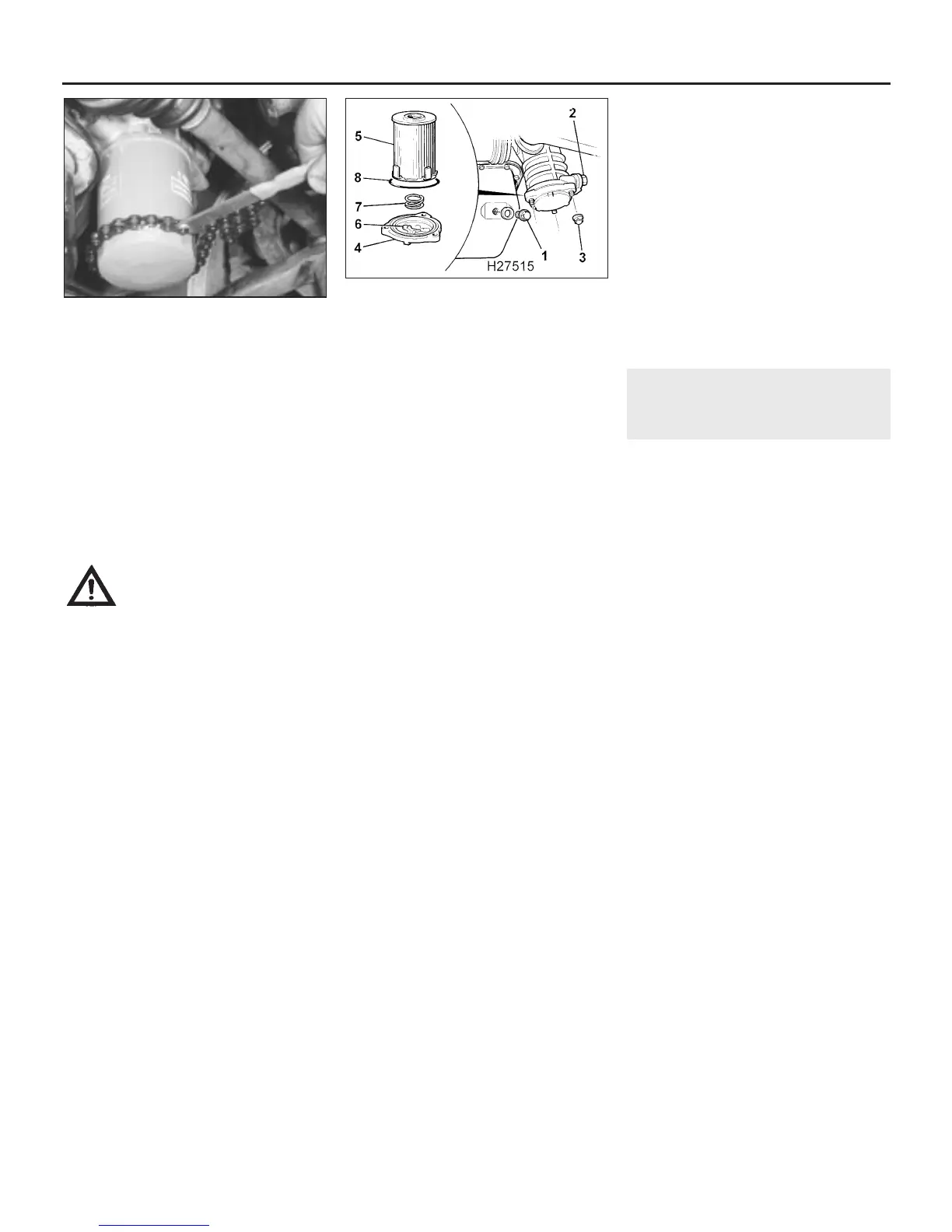

9 On all engines except the 2.5 litre V6, the oil

filter renewal procedure is relatively simple;

proceed as follows. Reposition the drain pan

under the oil filter then, using a filter removal

tool, unscrew the oil filter from the housing; be

prepared for some oil spillage (see

illustration). Check the old filter to make sure

that the rubber sealing ring hasn’t stuck to the

engine; if it has, carefully remove it. Withdraw

the filter, taking care to spill as little oil as

possible.

10 Using a clean, lint-free rag, wipe clean the

cylinder block around the filter mounting. If

there are no specific instructions supplied

with it, fit a new oil filter as follows. Apply a

light coating of clean engine oil to the filter’s

sealing ring. Screw the filter into position on

the engine until it seats, then tighten it through

a further half- to three-quarters of a turn only.

Tighten the filter by hand only - do not use any

tools.

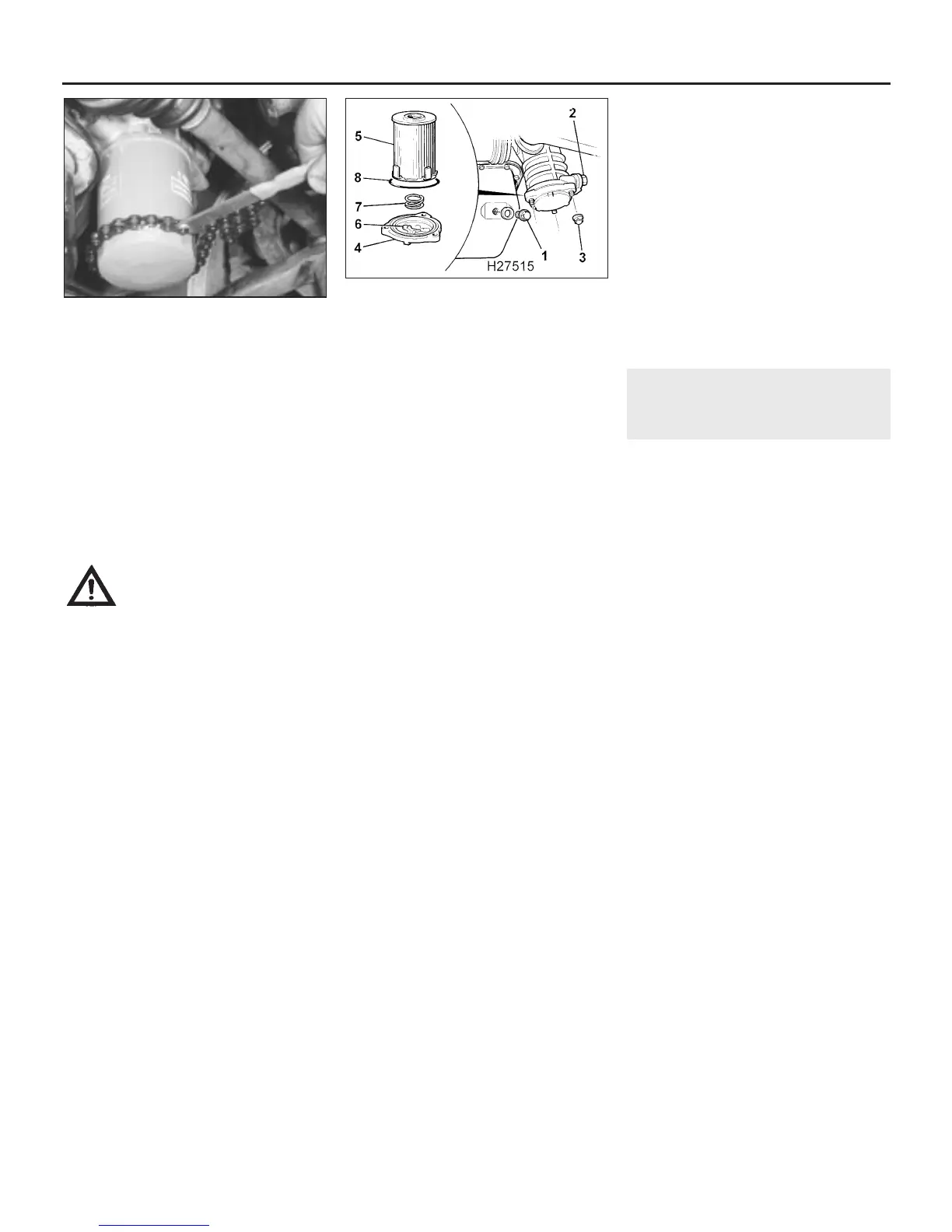

11 On 2.5 litre V6 engines the filter is a

cartridge contained within the filter housing.

12 Reposition the drain pan under the filter

assembly and first, drain the filter by

unscrewing the drain plug on the side of the

housing (see illustration). Refit the plug when

the filter has drained. Now undo the three

retaining nuts and withdraw the baseplate

from the filter assembly. As you do this be

prepared for oil spillage and catch the filter

cartridge and its components, which will fall

out and probably land in the oil as the

baseplate is removed. Retrieve the filter lower

spring and the sealing ring on the baseplate.

13 Clean the baseplate thoroughly and wipe

around the inside of the filter housing using a

clean lint-free rag.

14 Locate the new sealing ring in the

baseplate, then fit the spring to the locating

lugs in the baseplate. Locate the filter in the

housing, and refit the baseplate. Screw on the

three nuts and tighten them securely.

15 Remove the old oil and all tools from

under the vehicle, refit the access panel and

roadwheel, then lower the vehicle to the

ground.

16 Refill the engine with oil, using the correct

grade and type of oil, as given in the

“Lubricants, fluids and capacities” Section of

this Chapter. Pour in half the specified

quantity of oil first, then wait a few minutes for

the oil to fall to the sump. Continue adding oil

a small quantity at a time, until the level is up

to the lower notch on the dipstick. Adding

approximately 0.5 to 1.0 litre will raise the

level to the dipstick’s upper notch.

17 Start the engine. The oil pressure warning

light will take a few seconds to go out while

the new filter fills with oil; do not race the

engine while the light is on. Run the engine for

a few minutes, while checking for leaks

around the oil filter seal and the drain plug.

18 Switch off the engine, and wait a few

minutes for the oil to settle in the sump once

more. With the new oil circulated and the filter

now completely full, recheck the level on the

dipstick, adding more oil as necessary.

19 Dispose of the used engine oil safely, with

reference to “General repair procedures” in

the Reference Section of this manual.

8 Underbonnet check for fluid

leaks and hose condition

2

Caution: Renewal of air conditioning hoses

must be left to a dealer service

department or air conditioning specialist

who has the equipment to depressurise

the system safely. Never remove air

conditioning components or hoses until

the system has been depressurised.

General

1 High temperatures in the engine

compartment can cause the deterioration of

the rubber and plastic hoses used for engine,

accessory and emission systems operation.

Periodic inspection should be made for

cracks, loose clamps, material hardening and

leaks.

2 Carefully check the large top and bottom

radiator hoses, along with the other smaller-

diameter cooling system hoses and metal

pipes; do not forget the heater hoses/pipes

which run from the engine to the bulkhead.

Inspect each hose along its entire length,

replacing any that is cracked, swollen or

shows signs of deterioration. Cracks may

become more apparent if the hose is

squeezed.

3 Make sure that all hose connections are

tight. A leak in the cooling system will usually

show up as white- or rust-coloured deposits

on the areas adjoining the leak; if the spring

clamps that are used to secure the hoses in

this system appear to be slackening, they

should be renewed to prevent the possibility

of leaks.

4 Some other hoses are secured to their

fittings with clamps. Where clamps are used,

check that they haven’t lost their tension,

allowing the hose to leak. If clamps aren’t

used, make sure the hose has not expanded

and/or hardened where it slips over the fitting,

allowing it to leak.

5 Check all fluid reservoirs, filler caps, drain

plugs and fittings etc, looking for any signs of

leakage of oil, transmission and/or brake

hydraulic fluid, coolant and power steering

1•12 Every 6000 miles

7.12 Oil filter cartridge components on

2.5 litre V6 engines

1 Engine oil drain plug

2 Oil filter housing drain plug

3 Baseplate retaining nuts

4 Baseplate

5 Oil filter cartridge

6 Spring locating lugs

7 Spring

8 Sealing ring

7.9 Using a filter removal tool, unscrew

the oil filter from the housing

1380 Rover 800 Series Remake

Loading...

Loading...