wrench to tighten the new plugs to the

specified torque (see illustration).

3 To remove the spark plugs, first open the

bonnet; the plugs are easily reached at the

top of the engine or on the front and rear

facing sides. Note how the spark plug (HT)

leads are routed and secured by clips, and on

some engines, how they’re positioned along

the channel in the cylinder head cover. To

prevent the possibility of mixing up spark plug

(HT) leads, it is a good idea to work on one

spark plug at a time.

4 If the marks on the original-equipment

spark plug (HT) leads cannot be seen, mark

the leads 1 to 4 (or 1 to 6), to correspond to

the cylinder the lead serves (No 1 cylinder is at

the timing belt end of the engine on 4-cylinder

engines, and at the timing belt end of the

engine on the rear bank under the brake

master cylinder on V6 engines).

5 On 4-cylinder engines, undo the bolts

securing the spark plug cover to the centre of

the cylinder head, noting the accelerator cable

support bracket on early engines. Lift off the

cover and again, on early engines, release the

HT lead grommet from the end of the cover.

6 On all engines, pull the leads from the plugs

by gripping the rubber boot, not the lead,

otherwise the lead connection may be

fractured.

7 Unscrew the spark plugs, ensuring that the

socket is kept in alignment with each plug - if

the socket is forcibly moved to either side, the

porcelain top of the plug may be broken off. If

any undue difficulty is encountered when

unscrewing any of the spark plugs, carefully

check the cylinder head threads and tapered

sealing surfaces for signs of wear, excessive

corrosion or damage; if any of these

conditions is found, seek the advice of a

dealer as to the best method of repair.

8 As each plug is removed, examine it as

follows - this will give a good indication of the

condition of the engine. If the insulator nose of

the spark plug is clean and white, with no

deposits, this is indicative of a weak mixture.

9 If the tip and insulator nose are covered

with hard black-looking deposits, then this is

indicative that the mixture is too rich. Should

the plug be black and oily, then it is likely that

the engine is fairly worn, as well as the mixture

being too rich.

10 If the insulator nose is covered with light

tan to greyish-brown deposits, then the

mixture is correct, and it is likely that the

engine is in good condition.

11 If you are renewing the spark plugs,

purchase the new plugs, then check each of

them first for faults such as cracked insulators

or damaged threads. Note also that,

whenever the spark plugs are renewed as a

routine service operation, the spark plug (HT)

leads should be checked as described below.

12 The spark plug electrode gap is of

considerable importance as, if it is too large or

too small, the size of the spark and its efficiency

will be seriously impaired. The gap should be

set to the value given in the Specifications

Section of this Chapter. New plugs will not

necessarily be set to the correct gap, so they

should always be checked before fitting.

13 Special spark plug electrode gap

adjusting tools are available from most motor

accessory shops.

14 To set the electrode gap, measure the gap

with a feeler gauge or adjusting tool, and then

bend open, or closed, the outer plug electrode

until the correct gap is achieved (see

illustrations). The centre electrode should

never be bent, as this may crack the insulation

and cause plug failure, if nothing worse. If the

outer electrode is not exactly over the centre

electrode, bend it gently to align them.

15 Before fitting the spark plugs, check that

the threaded connector

sleeves at the top of the plugs are tight, and

that the plug exterior surfaces and threads are

clean. Brown staining on the porcelain,

immediately above the metal body, is quite

normal, and does not necessarily indicate a

leak between the body and insulator.

16 On installing the spark plugs, first check

that the cylinder head thread and sealing

surface are as clean as possible; use a clean

rag wrapped around a paintbrush to wipe

clean the sealing surface. Apply a smear of

copper-based grease or anti-seize compound

to the threads of each plug, and screw them

in by hand where possible.

17 When each spark plug is started correctly

on its threads, screw it down until it just seats

lightly, then tighten it to the specified torque

wrench setting.

18 Reconnect the spark plug (HT) leads in

their correct order, using a twisting motion on

the boot until it is firmly seated. On 4-cylinder

engines, refit the spark cover.

Spark plug (HT) lead and

distributor cap check

19 The spark plug (HT) leads should be

inspected one at a time, to prevent mixing up

1•14 Every 12 000 miles

11.14c . . . then use the end of the special

tool to adjust the gap

11.14b . . . or adjusting tool . . .11.14a Measure the spark plug gap with a

feeler gauge . . .

11.2 Tools required for spark plug

removal, gap adjustment and refitting

1380 Rover 800 Series Remake

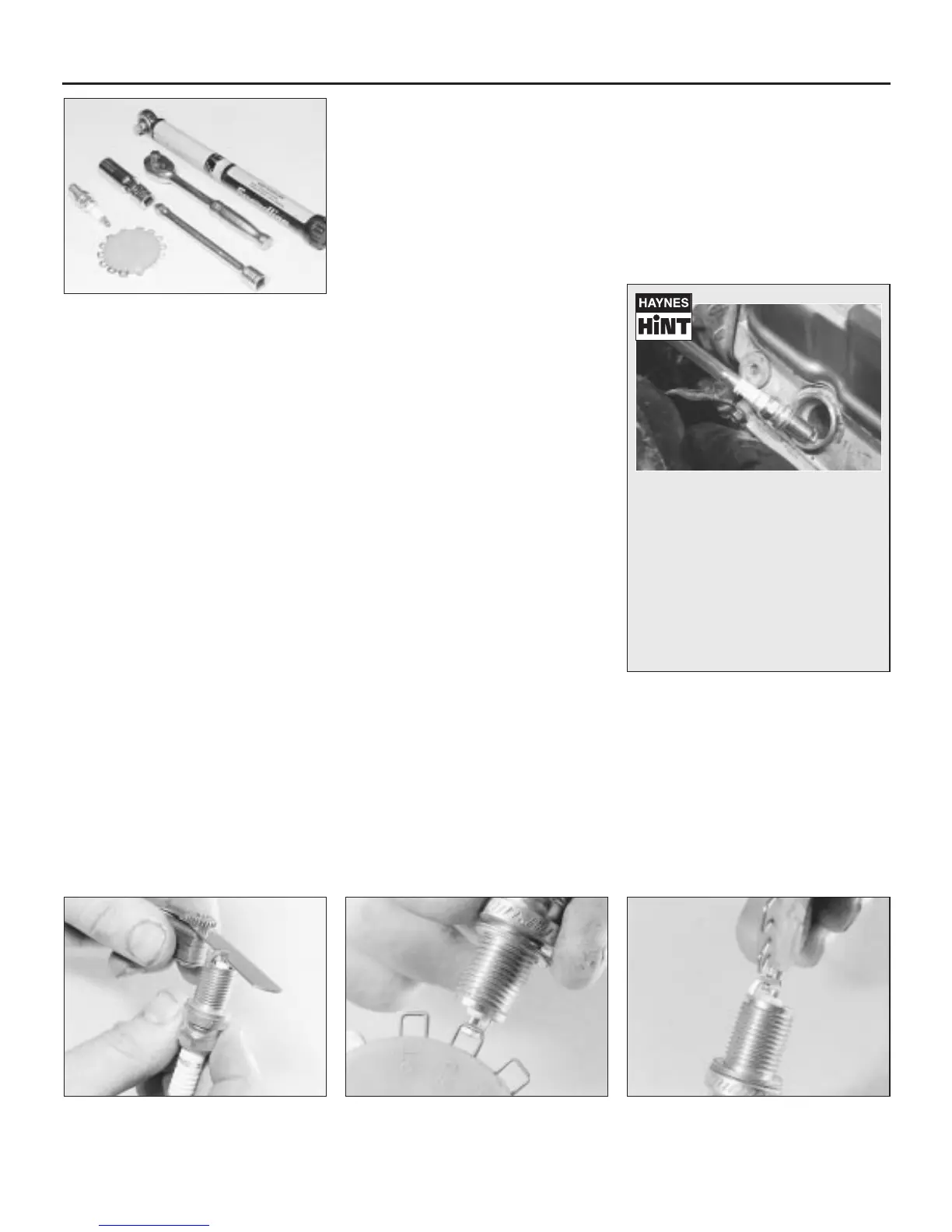

Take extra care to enter the plug

threads correctly, as the cylinder head

is of aluminium alloy - it’s often difficult

to insert spark plugs into their holes

without cross-threading them. To avoid

this possibility, fit a short piece of hose

over the end of the spark plug. The

flexible hose acts as a universal joint,

to help align the plug with the plug

hole. Should the plug begin to cross-

thread, the hose will slip on the spark

plug, preventing thread damage.

Loading...

Loading...