the firing order, which is essential for proper

engine operation. Gain access to the leads

and disconnect them as described above for

the spark plug check and renewal.

20 Check inside the boot for corrosion, which

will look like a white crusty powder. Clean this

off as much as possible; if it is excessive, or if

cleaning leaves the metal connector too badly

corroded to be fit for further use, the lead

must be renewed. Push the lead and boot

back onto the end of the spark plug. The boot

should fit tightly onto the end of the plug - if it

doesn’t, remove the lead and use pliers

carefully to crimp the metal connector inside

the boot until the fit is snug.

21 Using a clean rag, wipe the entire length

of the lead to remove built-up dirt and grease.

Once the lead is clean, check for burns,

cracks and other damage. Do not bend the

lead sharply, because the conductor might

break.

22 Inspect the remaining spark plug (HT)

leads, ensuring that each is securely fastened

at the distributor cap and spark plug when the

check is complete. If any sign of arcing,

severe connector corrosion, burns, cracks or

other damage is noticed, obtain new spark

plug (HT) leads, renewing them as a set. If

new spark plug leads are to be fitted, remove

and refit them one at a time, to avoid mix-ups

in the firing order.

23 Refer to Chapter 5 and remove the

distributor cap then thoroughly clean it inside

and out with a dry lint-free rag.

24 Examine the HT lead segments inside the

cap. If they appear badly burned or pitted

renew the cap. Also check the carbon brush

in the centre of the cap, ensuring that it is free

to move and stands proud of its holder. Make

sure that there are no sign of cracks or black

“tracking” lines running down the inside of the

cap, which will also mean renewal if evident.

Refit the cap as described in Chapter 5 on

completion.

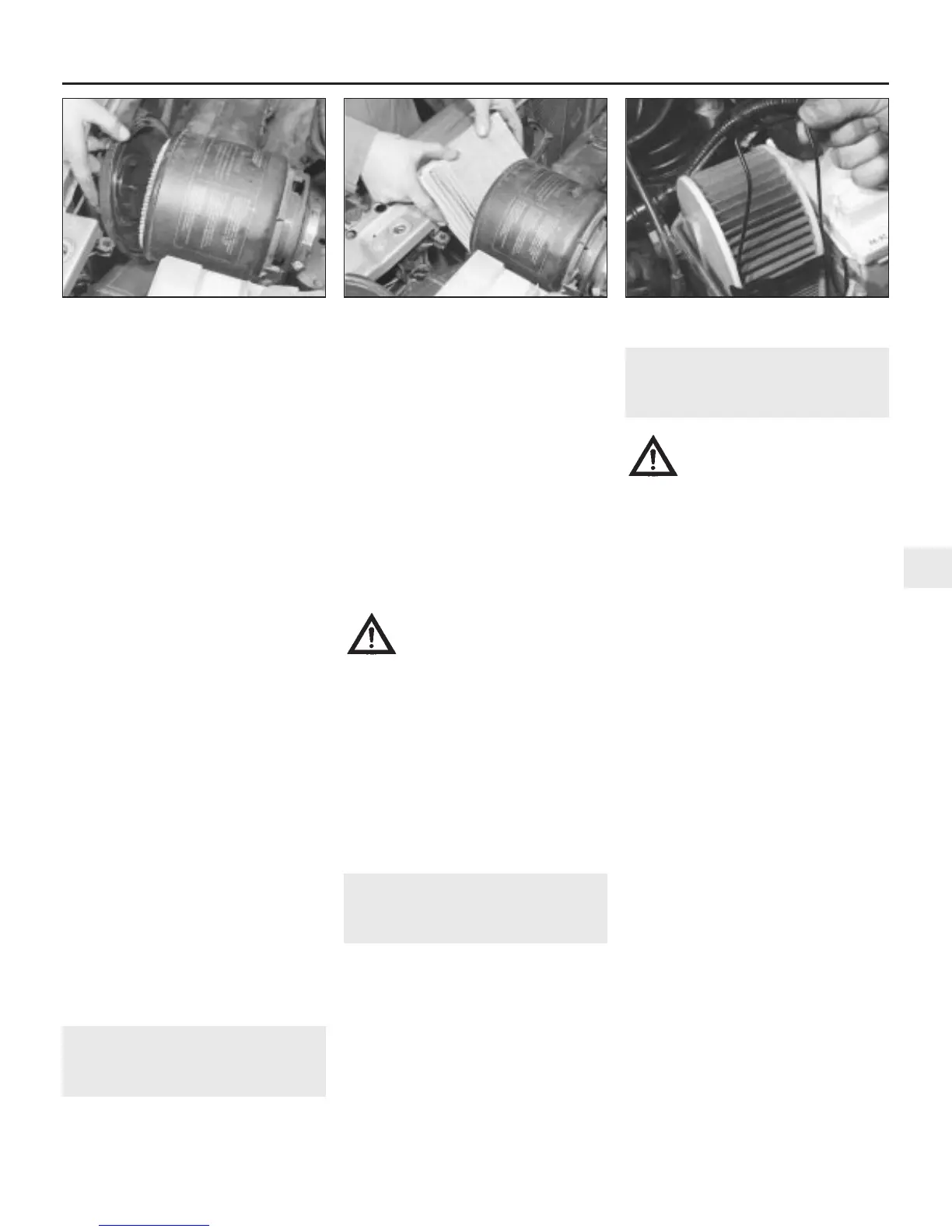

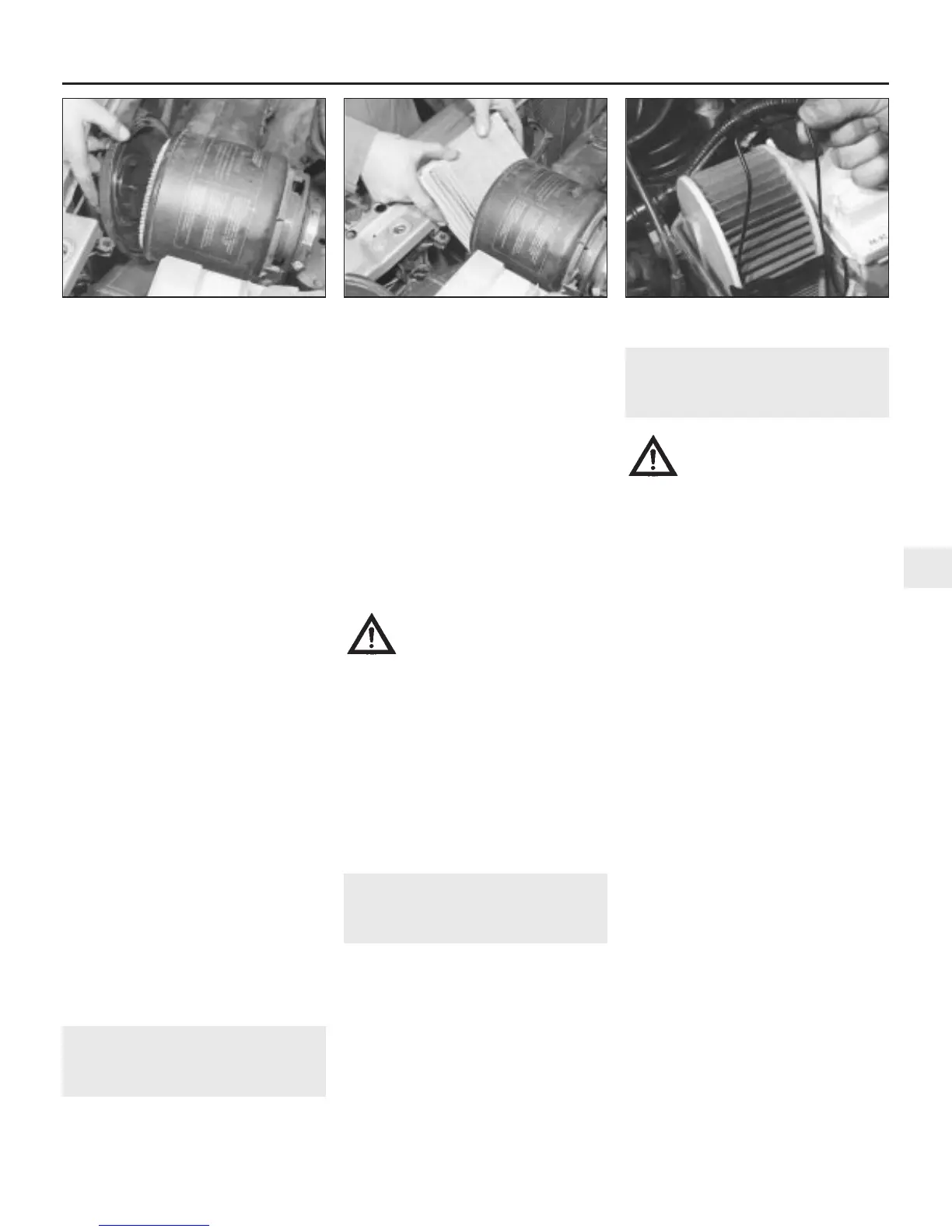

12 Air cleaner element renewal

1

1 The air cleaner filter element is located in

the air cleaner assembly mounted on the left-

hand side of the engine compartment. Undo

the retaining screws and/or release the clips,

and lift the air cleaner cover, disconnecting

the vacuum hose where fitted. Lift the element

out of the housing, together with its support

frame on V6 engines, and wipe out the

housing (see illustrations). Check that no

foreign matter is visible, either in the air intake

or in the housing.

2 If carrying out a routine service, the element

must be renewed regardless of its apparent

condition. If you are checking the element for

any other reason, inspect its lower surface; if

it is oily or very dirty, renew the element. If it is

only moderately dusty, it can be re-used by

blowing it clean from the upper to the lower

surface with compressed air.

Warning: Wear eye protection

when using compressed air!

Because it is a pleated-paper

type filter, it cannot be washed

or re-oiled. If it cannot be cleaned

satisfactorily with compressed air, discard

and renew it.

Caution: Never drive the vehicle with the

air cleaner filter element removed.

Excessive engine wear could result, and

backfiring could even cause a fire under

the bonnet.

3 Refitting is the reverse of the removal

procedure. Ensure that the element and cover

are securely seated, so that unfiltered air

cannot enter the engine.

13 Electrical system check

1

1 Check the operation of all external lights

and indicators (front and rear).

2 Check for satisfactory operation of the

instrument panel, its illumination and warning

lights, the switches and their function lights.

3 Check the horn(s) for satisfactory operation.

4 Check all other electrical equipment for

satisfactory operation.

5 Check all electrical wiring in the engine

compartment for correct routing, and for

any signs of physical or heat-damage or

chafing.

14 Battery check, maintenance

and charging

2

Warning: Certain precautions

must be followed when

checking and servicing the

battery. Hydrogen gas, which is

highly flammable, is always present in the

battery cells, so keep lighted tobacco and

all other open flames and sparks away

from the battery. The electrolyte inside the

battery is actually dilute sulphuric acid,

which will cause injury if splashed on your

skin or in your eyes. It will also ruin clothes

and painted surfaces. When disconnecting

the battery, always detach the negative

(earth) lead first and connect it last!

Note: Before disconnecting the battery, refer

to Section 1 of Chapter 5.

General

1 A routine preventive maintenance

programme for the battery in your vehicle is

the only way to ensure quick and reliable

starts. Before performing any battery

maintenance, make sure that you have the

proper equipment necessary to work safely

around the battery.

2 There are also several precautions that

should be taken whenever battery

maintenance is performed. Before servicing

the battery, always turn the engine and all

accessories off, and disconnect the lead from

the negative terminal of the battery - see

Chapter 5, Section 1.

3 The battery produces hydrogen gas, which

is both flammable and explosive. Never create

a spark, smoke, or light a match around the

battery. Always charge the battery in a well-

ventilated area.

4 Electrolyte contains poisonous and

corrosive sulphuric acid. Do not allow it to get

in your eyes, on your skin, or on your clothes.

Never ingest it. Wear protective safety glasses

when working near the battery. Keep children

away from the battery.

5 Note the external condition of the battery. If

the positive terminal and lead clamp on your

vehicle’s battery is equipped with a plastic

Every 12 000 miles 1•15

12.1c Lift the element out of the housing,

together with its support frame on V6 engines

12.1b . . . and element on 4-cylinder

engines with single-point fuel injection

12.1a Removing the air cleaner cover . . .

1

1380 Rover 800 Series Remake

Loading...

Loading...