cover or rubber protector, make sure that it’s

not torn or damaged. It should completely

cover the terminal. Look for any corroded or

loose connections, cracks in the case or

cover, or loose hold-down clamps. Check the

entire length of each lead for cracks and

frayed conductors.

6 If corrosion, which looks like white, fluffy

deposits is evident, particularly around the

terminals, the battery should be removed for

cleaning as described in Chapter 5, Section 2.

7 Clean the lead clamps thoroughly, using a

soft wire brush or a terminal cleaner, with a

solution of warm water and baking soda.

Wash the terminals and the top of the battery

case with the same solution, but make sure

that the solution doesn’t get into the battery.

When cleaning the leads, terminals and

battery top, wear safety goggles and rubber

gloves, to prevent any solution from coming in

contact with your eyes or hands. Wear old

clothes too - even when diluted, acid

splashed onto clothes will burn holes in them.

Wash all cleaned areas with plain water.

8 Make sure that the battery tray is in good

condition and the hold-down clamp nuts are

tight. If the battery is removed from the tray,

make sure no parts remain in the bottom of

the tray when the battery is refitted. When

refitting the hold-down clamp nuts, do not

overtighten them.

9 Information on jump starting can be found

at the front of this manual. For more detailed

battery checking procedures, refer to the

Haynes “Automobile Electrical and Electronic

Systems Manual”.

Cleaning

10 Corrosion on the hold-down components,

battery case and surrounding areas can be

removed with a solution of water and baking

soda. Thoroughly rinse all cleaned areas with

plain water.

11 Any metal parts of the vehicle damaged

by corrosion should be covered with a zinc-

based primer, then painted.

Charging

Warning: When batteries are

being charged, hydrogen gas,

which is very explosive and

flammable, is produced. Do not

smoke, or allow open flames, near a

charging or a recently-charged battery.

Wear eye protection when near the battery

during charging. Also, make sure the

charger is unplugged before connecting or

disconnecting the battery from the charger.

12 Slow-rate charging is the best way to

restore a battery that’s discharged to the

point where it will not start the engine. It’s also

a good way to maintain the battery charge in a

vehicle that’s only driven a few miles between

starts. Maintaining the battery charge is

particularly important in winter, when the

battery must work harder to start the engine,

and electrical accessories that drain the

battery are in greater use.

13 It’s best to use a one- or two-amp battery

charger (sometimes called a “trickle” charger).

They are the safest, and put the least strain on

the battery. They are also the least expensive.

For a faster charge, you can use a higher-

amperage charger, but don’t use one rated

more than 1/10th the amp/hour rating of the

battery (ie no more than 5 amps, typically).

Rapid boost charges that claim to restore the

power of the battery in one to two hours are

hardest on the battery, and can damage

batteries not in good condition. This type of

charging should only be used in emergency

situations.

14 The average time necessary to charge a

battery should be listed in the instructions that

come with the charger. As a general rule, a

trickle charger will charge a battery in 12 to

16 hours.

15 Seat belt check

1

1 Check the seat belts for satisfactory

operation and condition. Inspect the webbing

for fraying and cuts. Check that they retract

smoothly and without binding into their reels.

2 Check that the seat belt mounting bolts are

tight, and if necessary tighten them to the

specified torque wrench setting (see Chap-

ter 11).

16 Auxiliary drivebelts check

and renewal

2

General

1 The number and type of auxiliary drivebelts

depends on the engine, year of manufacture,

and whether or not the vehicle is equipped

with air conditioning. The belt will be either a

V-belt or a flat, multi-ribbed (or “polyvee”)

type. All the drivebelts are located on the

right-hand end of the engine and are driven

from the crankshaft pulley. Early “M” series

4-cylinder engines have an additional

drivebelt for the power steering pump, which

is driven from a pulley on the camshaft.

2 The good condition and proper tension of

the auxiliary drivebelts is critical to the

operation of the engine. Because of their

composition and the high stresses to which

they are subjected, drivebelts stretch and

deteriorate as they get older. They must,

therefore, be regularly inspected.

Check

3 With the engine switched off, open and

support the bonnet, then locate the auxiliary

drivebelts fitted to your car (Be very careful,

and wear protective gloves to minimise the

risk of burning your hands on hot

components, if the engine has recently been

running). For improved access, jack up the

front of the vehicle, support it securely on axle

stands, remove the roadwheel, then remove

the cover from inside the wheelarch.

4 Using an inspection light or a small electric

torch, and rotating the engine when necessary

with a spanner applied to the crankshaft

pulley bolt, check the whole length of the

drivebelt for cracks, separation of the rubber,

and torn or worn ribs. Also check for fraying

and glazing, which gives the drivebelt a shiny

appearance. Both sides of the drivebelt

should be inspected, and you will have to

twist the drivebelt to check the underside.

Use your fingers to feel the drivebelt where

you can’t see it. If you are in any doubt as to

the condition of the drivebelt, renew it.

Drivebelt tension - 4-cylinder

engines

Alternator drivebelt (early “M” series

engines)

5 Check that it is just possible to twist the

belt by hand through 90º at a point midway

between the two pulleys. If adjustment is

necessary, proceed as follows.

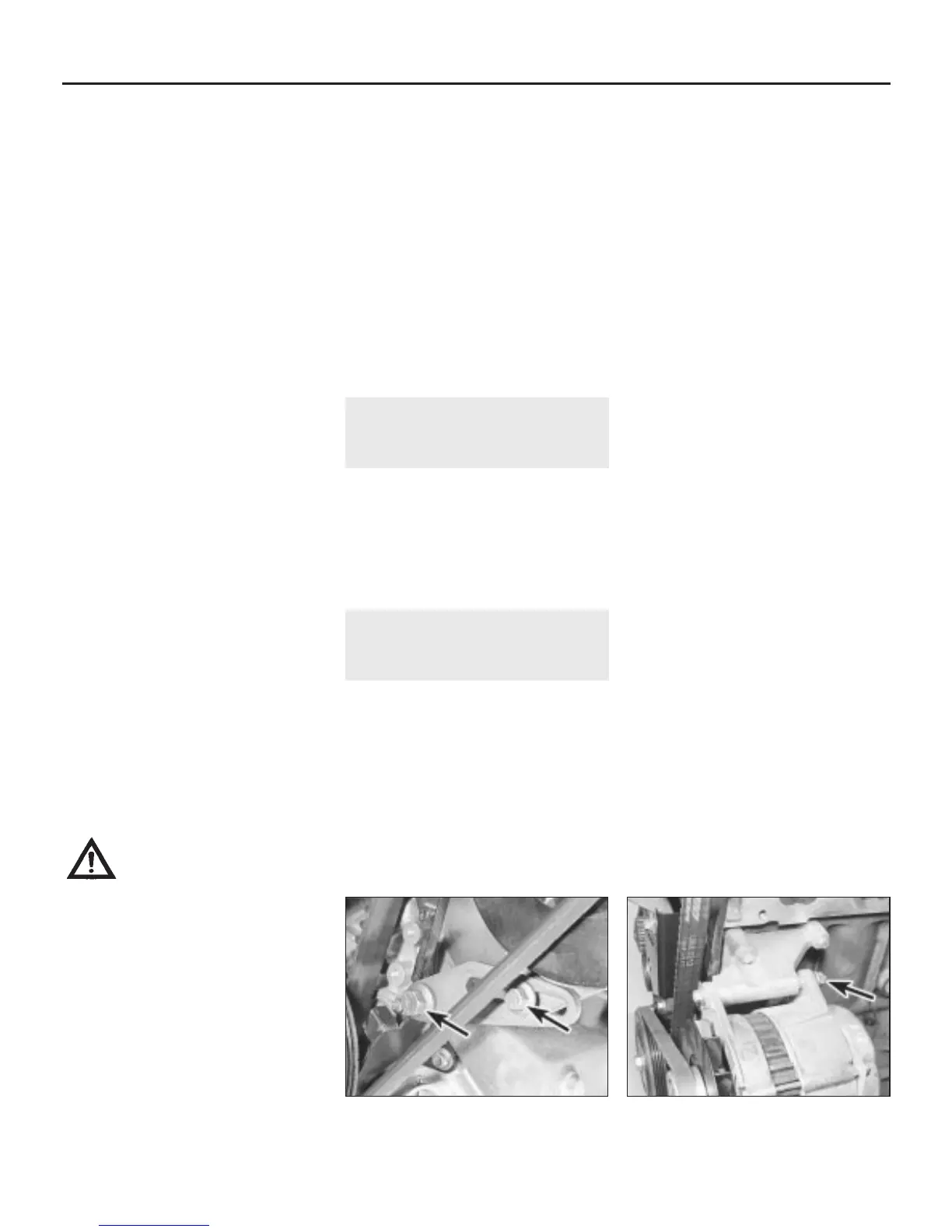

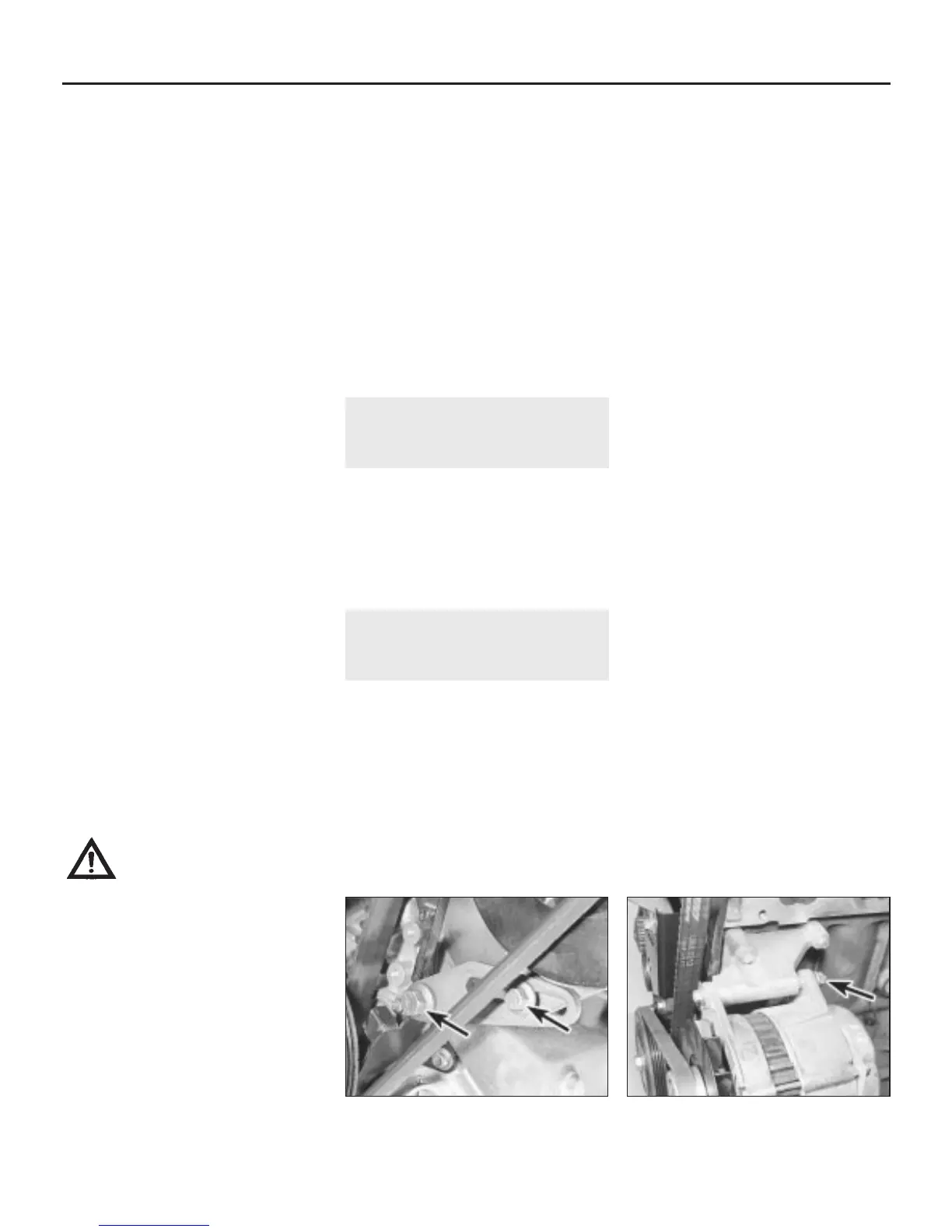

6 Slacken the two alternator adjustment

bracket bolts and the alternator pivot bolt and

nut (see illustrations).

7 Lever the alternator away from the engine

until the drivebelt is moderately tight. The

alternator must only be levered with care at

the drive end bracket. Hold the alternator in

this position and tighten the adjustment

bracket bolts and pivot nut and bolt.

1•16 Every 12 000 miles

16.6b . . . and pivot bolt retaining nut on

early “M” series 4-cylinder engines

16.6a Alternator adjustment bracket bolts

(arrowed) . . .

1380 Rover 800 Series Remake

Loading...

Loading...