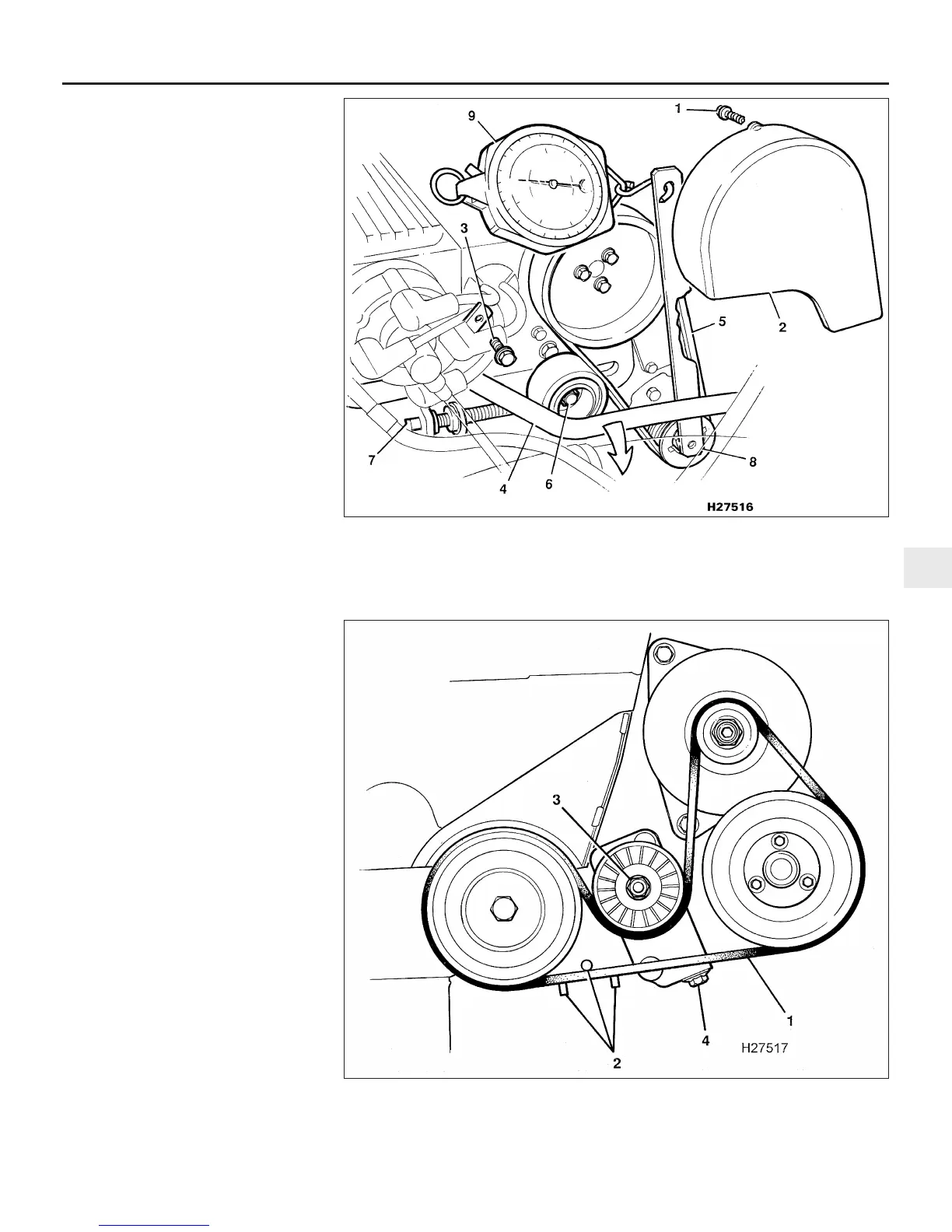

Power steering pump drivebelt (early

“M” series engines)

8 Refer to Chapter 4, Part A or B, and remove

the air cleaner components as necessary, for

access.

9 Undo the retaining screw and remove the

cover over the camshaft pulley (see illustration).

10 Undo the bolts securing the coolant

bypass pipe to the cylinder head and to the

main coolant pipe, and move the bypass pipe

aside as necessary for access.

11 To check and adjust the belt tension

accurately it will be necessary to obtain a

socket to fit the power steering pump pulley

retaining nut, a socket bar of at least 12 inches

in length, and a spring balance capable of

recording a minimum of 25 lbs. Make a paint

mark or similar on the socket bar, 12 inches up

from the centre of the square drive end.

12 Slacken the centre retaining nut on the

belt tensioner wheel, then turn the tension

adjuster bolt clockwise until the belt is slack.

Retighten the tensioner wheel retaining nut to

5.0 Nm.

13 Fit the socket and bar to the pump pulley

retaining nut, and position it so that the socket

bar is vertical.

14 Attach the spring balance to the socket

bar at the point marked 12 inches up from the

square drive end.

15 Turn the adjuster bolt anti-clockwise until

it takes a pull of 25 lbs to make the pump

pulley slip. This procedure is shown (see

illustration 16.9), but using the Rover special

tool. The socket and bar are a substitute for

this tool.

16 Remove the socket, bar and spring

balance, then turn the crankshaft until the

camshaft pulley has turned through 180º.

17 Check the belt tension again, and re-

adjust if necessary.

18 Now turn the tension adjuster bolt anti-

clockwise two complete turns.

19 Tighten the tensioner wheel retaining nut

fully to the specified torque.

20 Refit the coolant pipe retaining bolts, and

the cover over the camshaft pulley.

21 Refit the air cleaner components.

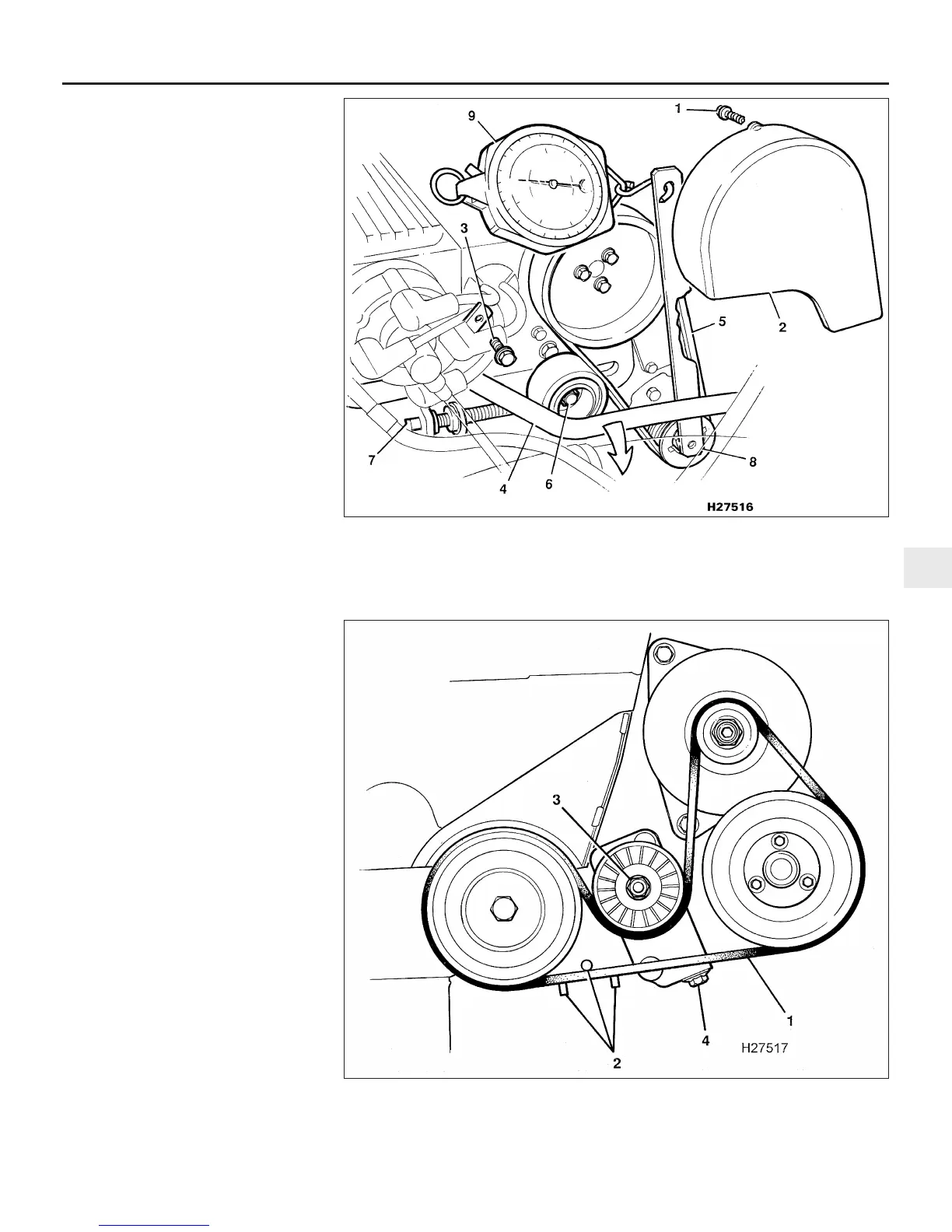

Alternator/power steering pump/air

conditioning compressor drivebelt

(later “M” series engines)

22 Accurate tensioning of the drivebelt on

cars with this arrangement can only be

achieved with the Rover belt tensioning tool,

and ideally this operation should be carried

out by a Rover dealer. However, if a new belt

has been fitted, or if the existing tension is

extremely slack, a rough approximation as a

temporary measure can be achieved using the

following procedure.

23 To adjust the belt tension, slacken the idler

pulley retaining nut, then turn the adjuster bolt

clockwise to increase the tension or anti-

clockwise to decrease it, until it is just possible

to twist the belt by hand through 90º at a point

midway between the crankshaft and power

steering pump pulleys (see illustration).

Every 12 000 miles 1•17

16.23 Drivebelt adjustment on later “M” series 4-cylinder engines

1 Drivebelt 2 Checking gauge - Rover

special tool

3 Idler pulley retaining nut

4 Adjuster bolt

16.9 Power steering pump drivebelt adjustment on early “M” series 4-cylinder engines

1 Camshaft pulley cover

retaining screw

2 Camshaft pulley cover

3 Coolant pipe retaining bolt

4 Coolant pipe

5 Drivebelt

6 Belt tensioner wheel centre

retaining nut

7 Tension adjuster bolt

8 Rover special tool for

checking tension

9 Spring balance

1

1380 Rover 800 Series Remake

Loading...

Loading...