24 When the tension is correct, tighten the

idler pulley retaining nut to the specified

torque and lower the car to the ground.

Alternator/power steering pump/air

conditioning compressor drivebelt

(“T” series engines)

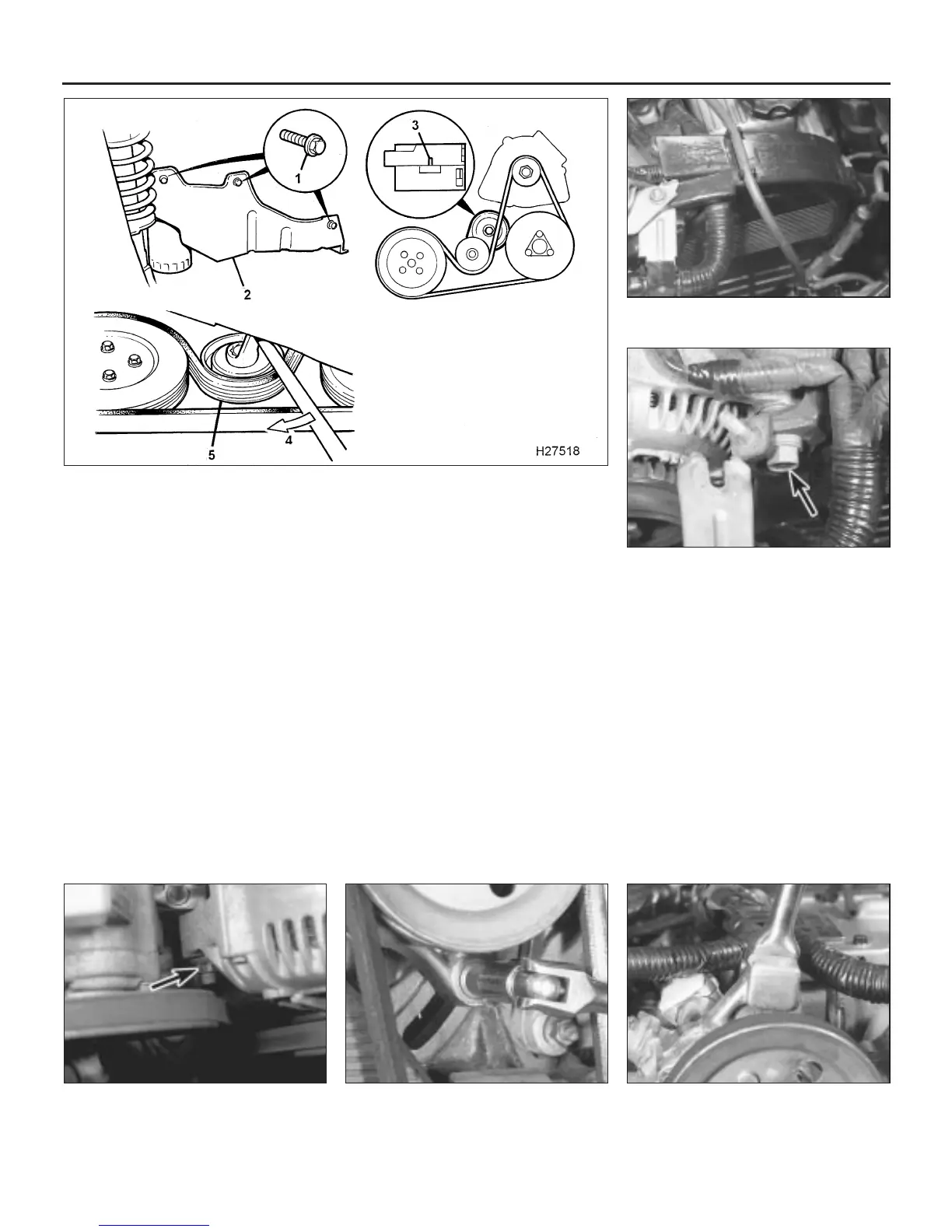

25 “T” series engines are fitted with an

automatic drivebelt tensioner incorporating a

wear indicator to show when the belt has

stretched too far for the tensioner to maintain

correct adjustment (see illustration).

26 To check the tension, observe the wear

indicator and make sure that the pointer has

not reached the right-hand end of the slot. If it

hasn’t, all is well, and no further action is

necessary; if it has, renew the belt.

Drivebelt tension - V6 engines

Alternator drivebelt

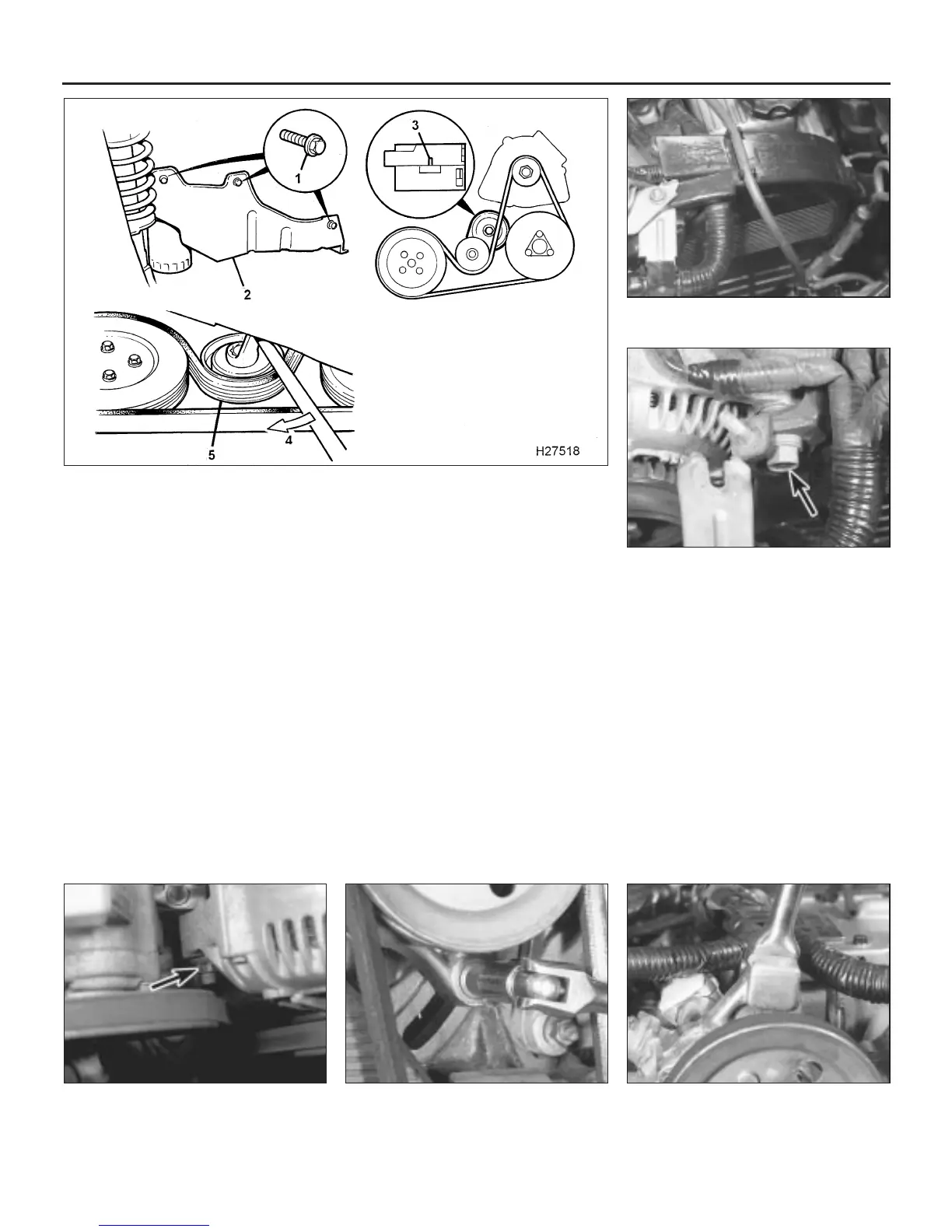

27 Undo the three bolts and one nut securing

the power steering pump and alternator pulley

covers to the top of the engine. Move the

pipes and cables clear and lift off the covers

(see illustration).

28 The belt tension is correct when it is just

possible to deflect the belt by 18 to 22 mm at

the mid-point of its run, under moderate finger

pressure. If adjustment is required, proceed

as follows.

29 Slacken the alternator side pivot bolt and

lower mounting nut, then turn the adjusting

bolt on the side of the unit as necessary to

achieve the correct tension (see

illustrations).

30 Tighten the pivot and mounting nuts and

bolts and refit the covers to the top of the

engine.

Power steering pump drivebelt

31 Undo the three bolts and one nut securing

the power steering pump and alternator pulley

covers to the top of the engine. Move the

pipes and cables clear and lift off the covers.

32 The belt tension is correct when it is just

possible to deflect the belt by 18 to 22 mm at

the mid-point of its run, under moderate finger

pressure. If adjustment is required, proceed

as follows.

33 Slacken the pump adjusting nut and

mounting bolt, then engage the end of a

1/2 inch square drive socket bar in the hole at

the rear of the large lug on top of the pump

(see illustrations). Using the bar, move the

pump as necessary, until the belt tension is

correct, then tighten the adjusting and

mounting nut and bolt.

Air conditioning compressor drivebelt

34 The belt tension is correct when it is just

possible to deflect the belt by 7 to 9 mm at a

point mid-way between the crankshaft pulley

and the tensioner jockey wheel, under

1•18 Every 12 000 miles

16.33b . . . then engage the end of a

socket bar in the lug on top of the pump to

adjust the belt

16.29a . . . slacken the alternator side

pivot bolt (arrowed) . . .

16.33a Slacken the V6 engine power

steering pump adjusting nut . . .

16.29b . . . and lower mounting nut

(arrowed), then turn the adjusting bolt to

achieve the correct tension

16.27 On V6 engines, remove the pulley

covers over the top of the engine . . .

16.25 Drivebelt adjustment details on “T” series engines

1 Wheelarch cover retaining

bolts

2 Wheelarch cover

3 Tensioner wear indicator

4 Releasing the tensioner for

belt renewal

5 Drivebelt

1380 Rover 800 Series Remake

Loading...

Loading...