moderate finger pressure. If adjustment is

required, proceed as follows.

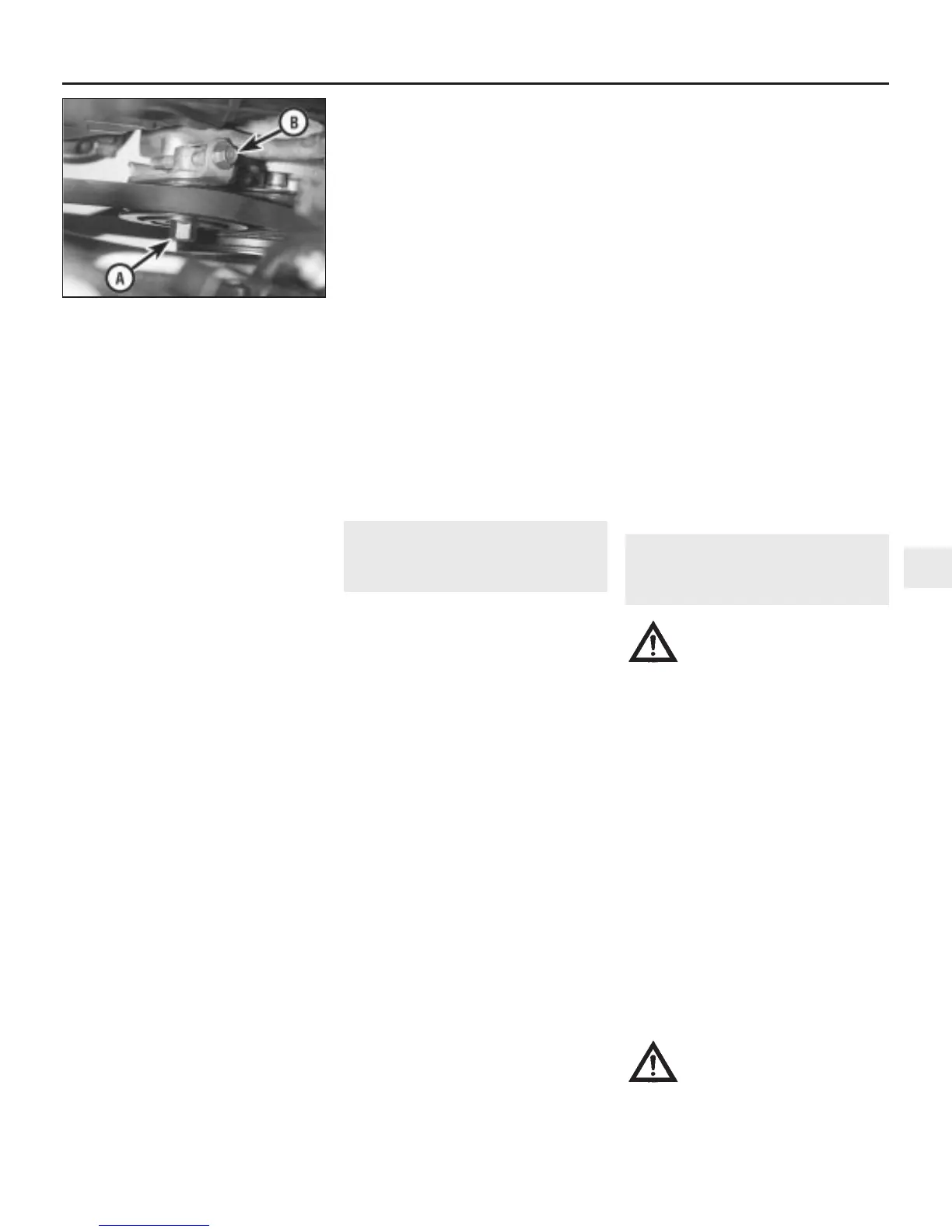

35 Slacken the bolt in the centre of the

tensioner jockey wheel, then turn the

adjusting bolt, behind the adjuster, to obtain

the correct belt tension (see illustration).

When the adjustment is correct, tighten the

jockey wheel bolt.

Renewal - 4-cylinder engines

36 Open the bonnet, jack up the front of the

vehicle (where applicable) and support it

securely on an axle stands, remove the

roadwheel, then remove the cover from inside

the wheelarch.

37 The routing of the drivebelt around the

pulleys is dependant on the drivebelt type and

whether or not air conditioning is fitted. Before

removing the drivebelt, it’s a good idea to

sketch the belt run around the pulleys; this will

save a lot of frustration when it comes to

refitting.

38 If the existing drivebelt is to be refitted,

mark it, or note the maker’s markings on its

flat surface, so that it can be installed in the

same way.

39 To renew the drivebelt, slacken the belt

tension fully as described above according to

type, noting that where an automatic

tensioner is fitted, it is only necessary to turn

the tensioner centre bolt clockwise, using a

spanner, to release the belt tension. Slip the

belt off the pulleys then fit the new belt

ensuring that it is routed correctly. With the

belt in position, adjust the tension as

previously described, or simply release the

tensioner bolt.

40 Using a spanner applied to the crankshaft

pulley bolt, rotate the crankshaft through at

least two full turns clockwise to settle the

drivebelt on the pulleys, then check that the

drivebelt is properly installed.

41 Refit the cover and roadwheel, then lower

the vehicle to the ground.

Renewal - V6 engines

42 Open the bonnet, jack up the front of the

vehicle (where applicable) and support it

securely on an axle stands, remove the

roadwheel, then remove the cover from inside

the wheelarch.

43 If the existing drivebelt is to be refitted,

mark it, or note the maker’s markings on its

flat surface, so that it can be installed the

same way.

44 Depending on which drivebelt is to be

renewed, it will probably be necessary to

remove one (or both) of the other drivebelts

first, to gain access. Note also, that if the

power steering pump drivebelt is to be

renewed, it will be necessary to support the

engine under the sump on a jack (with

interposed block of wood) and undo the two

bolts on the right-hand engine mounting, to

allow the belt to pass through.

45 To renew the drivebelt, slacken the belt

tension fully as described above according to

type. Slip the belt off the pulleys then fit the

new belt. With the belt in position, refit the

engine mounting bolts (where applicable) and

adjust the tension as previously described.

46 Using a spanner applied to the crankshaft

pulley bolt, rotate the crankshaft through at

least two full turns clockwise to settle the

drivebelt on the pulleys, then check that the

drivebelt is properly installed.

47 Refit the cover and roadwheel, then lower

the vehicle to the ground.

17 Engine compartment wiring

check

2

1 With the vehicle parked on level ground,

apply the handbrake firmly and open the

bonnet. Using an inspection light or a small

electric torch, check all visible wiring within

and beneath the engine compartment.

2 What you are looking for is wiring that is

obviously damaged by chafing against sharp

edges, or against moving suspension/

transmission components and/or the auxiliary

drivebelts, by being trapped or crushed

between carelessly-refitted components, or

melted by being forced into contact with the

hot engine castings, coolant pipes, etc. In

almost all cases, damage of this sort is

caused in the first instance by incorrect

routing on reassembly after previous work has

been carried out.

3 Depending on the extent of the problem,

damaged wiring may sometimes be repaired

by rejoining the break or splicing-in a new

length of wire, using solder to ensure a good

connection, and remaking the insulation with

adhesive insulating tape or heat-shrink tubing,

as appropriate. If the damage is extensive,

given the implications for the vehicle’s future

reliability, the best long-term answer may well

be to renew that entire section of the loom,

however expensive this may appear.

4 When the actual damage has been

repaired, ensure that the wiring loom is re-

routed correctly, so that it is clear of other

components, and not stretched or kinked, and

is secured out of harm’s way using the plastic

clips, guides and ties provided.

5 Check all electrical connectors, ensuring

that they are clean, securely fastened, and

that each is locked by its plastic tabs or wire

clip, as appropriate. If any connector shows

external signs of corrosion (accumulations of

white or green deposits, or streaks of “rust”),

or if any is thought to be dirty, it must be

unplugged and cleaned using electrical

contact cleaner. If the connector pins are

severely corroded, the connector must be

renewed; note that this may mean the renewal

of that entire section of the loom - see your

local Rover dealer for details.

6 If the cleaner completely removes the

corrosion to leave the connector in a

satisfactory condition, it would be wise to

pack the connector with a material which will

exclude dirt and moisture, preventing the

corrosion from occurring again.

7 Check the condition of the battery

connections - remake the connections or

renew the leads if a fault is found. Use the

same techniques to ensure that all earth

points in the engine compartment provide

good electrical contact through clean, metal-

to-metal joints, and that all are securely

fastened.

8 Refer to Section 11 for details of spark plug

(HT) lead checks.

18 Air conditioning system

check

1

Warning: The air conditioning

system is under high pressure. Do

not loosen any fittings or remove

any components until after the

system has been discharged. Air conditioning

refrigerant must be properly discharged into

an approved type of container, at a dealer

service department or an automotive air

conditioning repair facility capable of

handling the refrigerant safely. Always wear

eye protection when disconnecting air

conditioning system fittings.

1 The following maintenance checks should

be performed on a regular basis, to ensure

that the air conditioner continues to operate at

peak efficiency:

(a) Check the auxiliary drivebelt. If it’s worn

or deteriorated, renew it (see Section 16).

(b) Check the system hoses. Look for cracks,

bubbles, hard spots and deterioration.

Inspect the hoses and all fittings for oil

bubbles and seepage. If there’s any

evidence of wear, damage or leaks, renew

the hose(s).

(c) Inspect the condenser fins for leaves,

insects and other debris. Use a “fin

comb” or compressed air to clean the

condenser.

Warning: Wear eye protection

when using compressed air!

(d) Check that the drain tube from the front

of the evaporator is clear - note that it is

normal to have clear fluid (water) dripping

Every 12 000 miles 1•19

16.35 Air conditioning compressor

drivebelt tensioner jockey wheel bolt (A),

and adjusting bolt (B) on V6 engines

1

1380 Rover 800 Series Remake

Loading...

Loading...