from this while the system is in operation,

to the extent that quite a large puddle can

be left under the vehicle when it is parked.

2 It’s a good idea to operate the system for

about 30 minutes at least once a month,

particularly during the winter. Long term non-

use can cause hardening, and subsequent

failure, of the seals.

3 Because of the complexity of the air

conditioning system and the special

equipment necessary to service it, in-depth

fault diagnosis and repairs are not included in

this manual. For more complete information

on the air conditioning system, refer to the

Haynes “Automotive Heating and Air

Conditioning Manual”.

4 The most common cause of poor cooling is

simply a low system refrigerant charge. If a

noticeable drop in cool air output occurs, the

following quick check will help you determine

if the refrigerant level is low.

5 Warm the engine up to normal operating

temperature.

6 Place the air conditioning temperature

selector at the coldest setting, and put the

blower at the highest setting. Open the doors

- to make sure the air conditioning system

doesn’t cycle off as soon as it cools the

passenger compartment.

7 With the compressor engaged - the clutch

will make an audible click, and the centre of

the clutch will rotate - feel the inlet and outlet

pipes at the compressor. One side should be

cold, and one hot. If there’s no perceptible

difference between the two pipes, there’s

something wrong with the compressor or the

system. It might be a low charge - it might be

something else. Take the vehicle to a dealer

service department or an automotive air

conditioning specialist.

19 Engine base idle speed and

CO content check

4

Refer to the appropriate Parts of Chapter 4.

20 Manual transmission oil level

check

1

1 The manual transmission does not have a

dipstick. To check the oil level, raise the

vehicle and support it securely on axle stands,

making sure that the vehicle is level. On the

left-hand side of the transmission casing, to

the rear of the constant velocity joint, you will

see the filler/level plug. Wipe around the plug

with a rag, then unscrew and remove it. If the

level is correct, the oil should be up to the

lower edge of the hole.

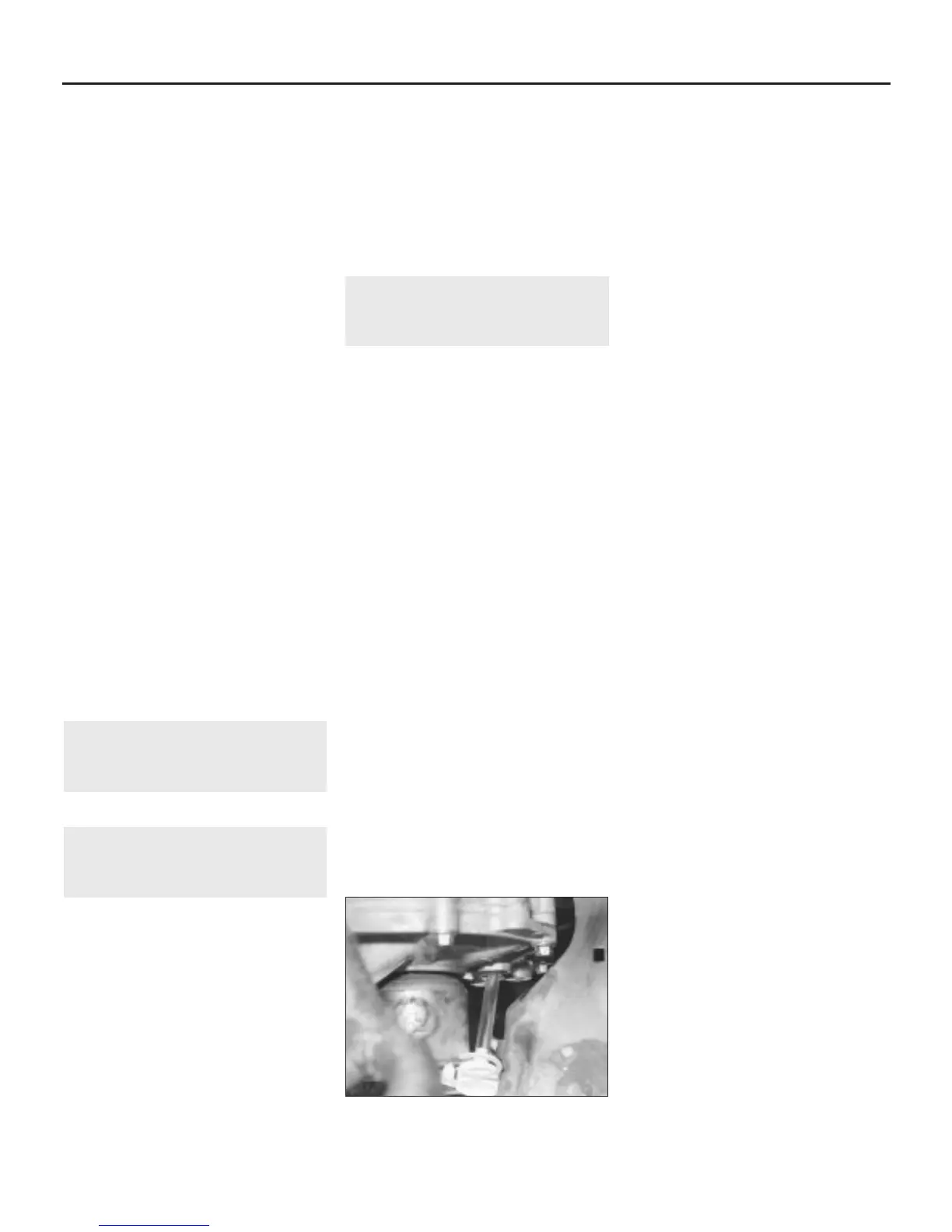

2 If the transmission needs more lubricant (if

the oil level is not up to the hole), use a

syringe, or a plastic bottle and tube, to add

more (see illustration). Stop filling the

transmission when the lubricant begins to run

out of the hole. Make sure that you refer to

“Lubricants, fluids and capacities” at the

beginning of this Chapter for the correct grade

of lubricant to use, according to transmission

type.

3 Refit the filler/level plug, and tighten it to the

specified torque wrench setting. Drive the

vehicle a short distance, then check for leaks.

4 A need for regular topping-up can only be

due to a leak, which should be found and

rectified without delay.

21 Steering, suspension and

roadwheel check

1

Front suspension and steering

check

1 Apply the handbrake, then raise the front of

the vehicle and support it on axle stands.

2 Visually inspect the balljoint dust covers and

the steering gear gaiters for splits, chafing or

deterioration. Any wear of these components

will cause loss of lubricant, together with dirt

and water entry, resulting in rapid deterioration

of the balljoints or steering gear.

3 Check the power-assisted steering fluid

hoses for chafing or deterioration, and the

pipe and hose unions for fluid leaks. Also

check for signs of fluid leakage under

pressure from the steering gear rubber

gaiters, which would indicate failed fluid seals

within the steering gear.

4 Check for signs of fluid leakage around the

shock absorber body, or from the rubber boot

around the piston rod (where fitted). Should

any fluid be noticed, the shock absorber is

defective internally, and renewal is necessary.

5 Grasp the roadwheel at the 12 o’clock and

6 o’clock positions, and try to rock it. Very

slight free play may be felt, but if the

movement is appreciable, further investigation

is necessary to determine the source.

Continue rocking the wheel while an assistant

depresses the footbrake. If the movement is

now eliminated or significantly reduced, it is

likely that the hub bearings are at fault. If the

free play is still evident with the footbrake

depressed, then there is wear in the

suspension joints or mountings.

6 Now grasp the wheel at the 9 o’clock and

3 o’clock positions, and try to rock it as

before. Any movement felt now may again be

caused by wear in the hub bearings or the

steering track rod balljoints. If the outer track

rod end balljoint is worn, the visual movement

will be obvious. If the inner joint is suspect, it

can be felt by placing a hand over the rack-

and-pinion rubber gaiter, and gripping the

track rod. If the wheel is now rocked,

movement will be felt at the inner joint if wear

has taken place.

7 Using a large screwdriver or flat bar, check

for wear in the suspension mounting bushes

by levering between the relevant suspension

component and its attachment point. Some

movement is to be expected as the mountings

are made of rubber, but excessive wear

should be obvious. Also check the condition

of any visible rubber bushes, looking for splits,

cracks or contamination of the rubber.

8 With the vehicle standing on its wheels,

have an assistant turn the steering wheel

back-and-forth, about an eighth of a turn each

way. There should be very little, if any, lost

movement between the steering wheel and

roadwheels. If this is not the case, closely

observe the joints and mountings previously

described, but in addition, check the steering

column universal joints for wear, and also

check the rack-and-pinion steering gear itself.

9 The efficiency of the shock absorber may

be checked by bouncing the car at each front

corner. Generally speaking, the body will

return to its normal position and stop after

being depressed. If it rises and returns on a

rebound, the shock absorber is probably

suspect. Examine also the shock absorber

upper and lower mountings for any signs of

wear.

Rear suspension check

10 Chock the front wheels, then raise the rear

of the vehicle and support it on axle stands.

11 Check the rear hub bearings for wear,

using the method described for the front hub

bearings (paragraph 4).

12 Using a large screwdriver or flat bar,

check for wear in the suspension mounting

bushes by levering between the relevant

suspension component and its attachment

point. Some movement is to be expected as

the mountings are made of rubber, but

excessive wear should be obvious. Check the

condition of the shock absorbers as

described previously.

Roadwheel check and balancing

13 Periodically remove the roadwheels, and

clean any dirt or mud from the inside and

outside surfaces. Examine the wheel rims for

signs of rusting, corrosion or other damage.

Light alloy wheels are easily damaged by

“kerbing” whilst parking, and similarly, steel

wheels may become dented or buckled.

Renewal of the wheel is very often the only

course of remedial action possible.

14 The balance of each wheel and tyre

1•20 Every 12 000 miles

20.2 Topping up the manual transmission

oil

1380 Rover 800 Series Remake

Loading...

Loading...