at the front left-hand side of the engine. Note

the condition and colour of the fluid on the

dipstick.

5 Wipe the fluid from the dipstick with a clean

rag, and re-insert it into the filler tube until the

cap seats.

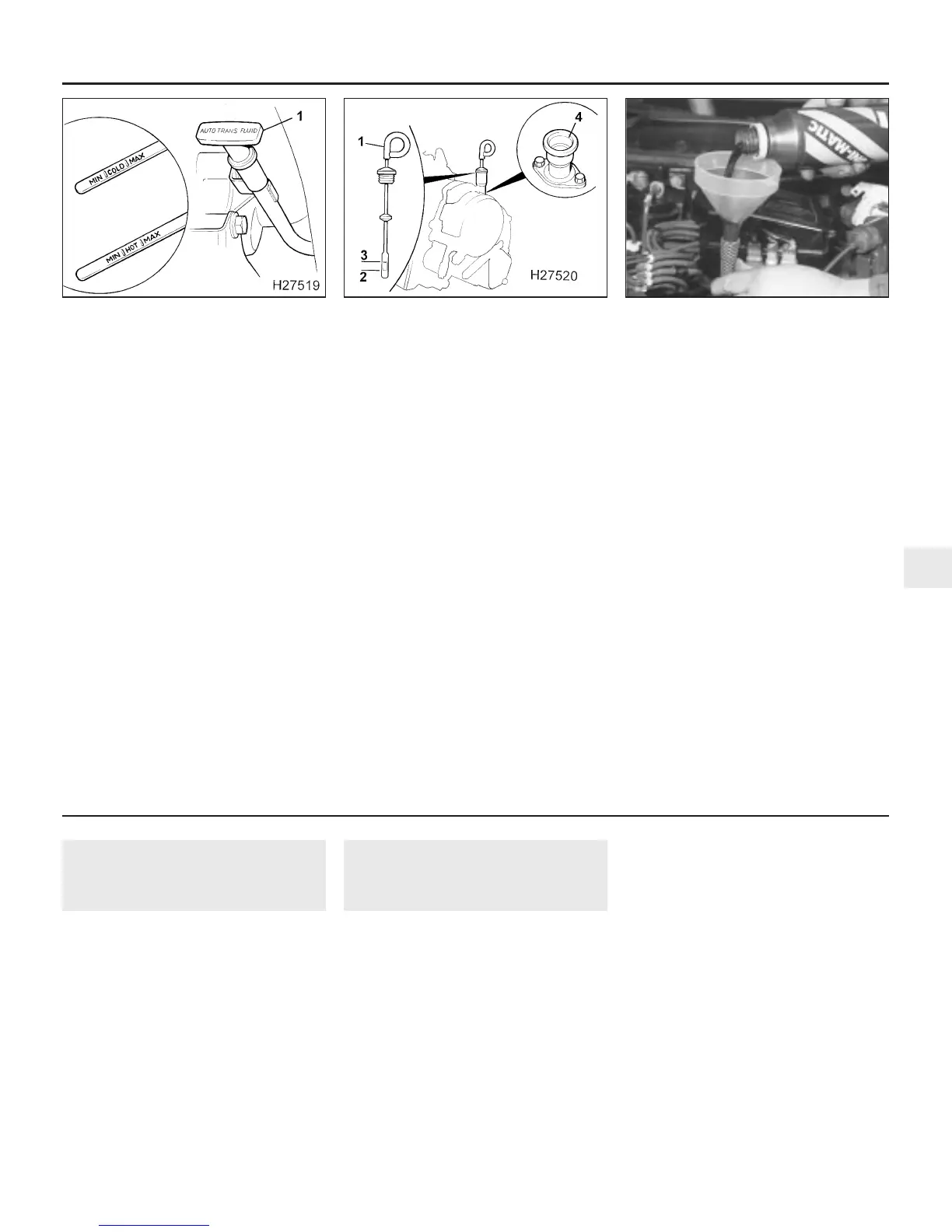

6 Pull the dipstick out again, and note the

fluid level. The level should be between the

“MIN” and “MAX” marks, on the side of the

dipstick marked “HOT” (see illustration). If

the level is on the “MIN” mark, stop the

engine, and add the specified automatic

transmission fluid through the dipstick tube,

using a clean funnel if necessary. It is

important not to introduce dirt into the

transmission when topping-up.

7 Add the fluid a little at a time, and keep

checking the level as previously described

until it is correct. The difference between the

“MIN” and “MAX” marks on the dipstick is

approximately 0.3 litre.

V6 engine models

8 Park the vehicle on level ground, apply the

handbrake, and start the engine. While the

engine is idling, depress the brake pedal and

move the selector lever to the “P” (PARK)

position.

9 Switch off the engine and wait one minute.

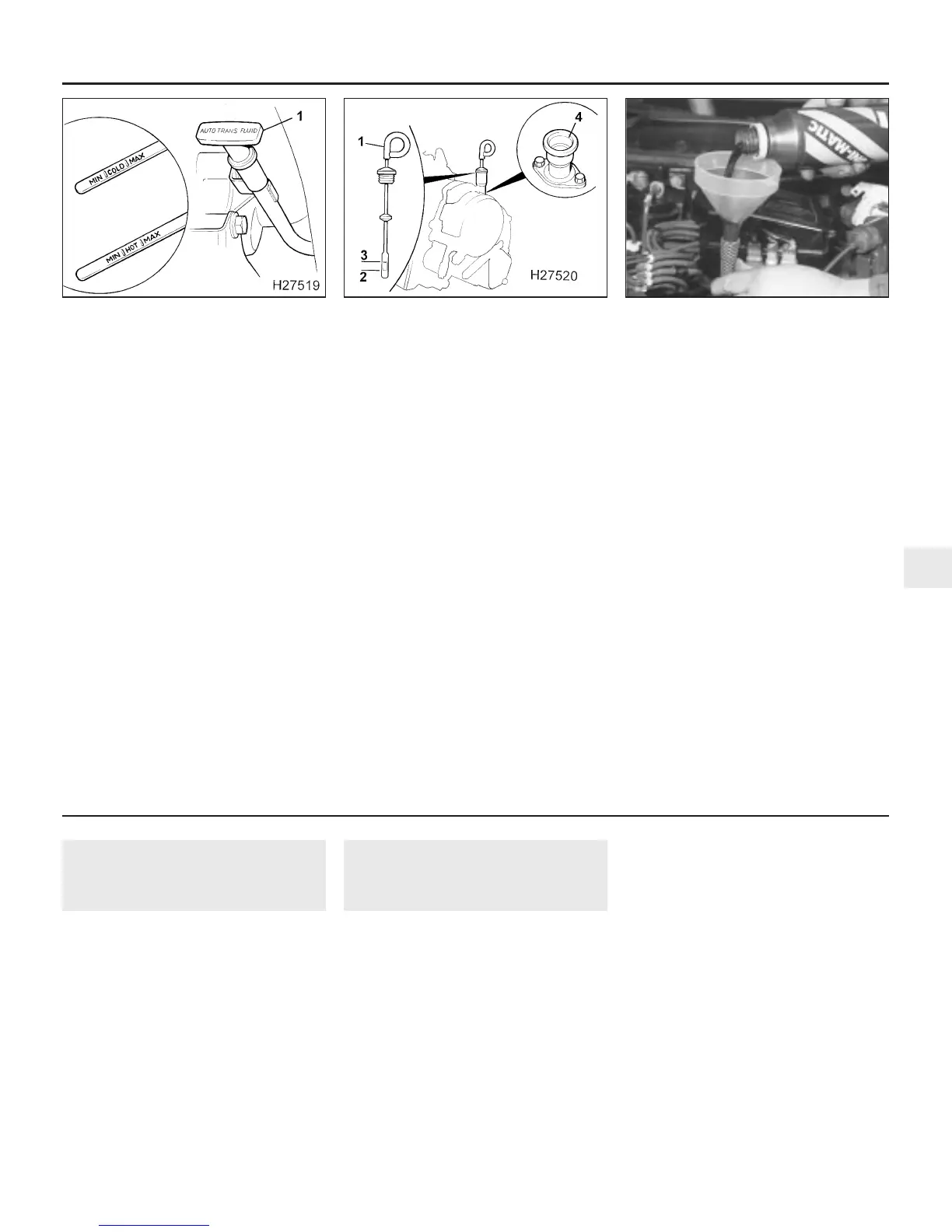

10 Remove the dipstick from its tube which

is located at the rear left-hand side of the

engine. The dipstick is mounted low down, on

top of the transmission casing and access is

not very good (see illustration). Note the

condition and colour of the fluid on the

dipstick.

11 Wipe the fluid from the dipstick with a

clean rag, and re-insert it into the filler tube

until the cap seats.

12 Pull the dipstick out again, and note the

fluid level. The level should be within the

shaded sector on the blade. If the level is

below or very near to the bottom of the

shaded sector, add the specified automatic

transmission fluid through the dipstick tube,

using a clean funnel (see illustration). It is

important not to introduce dirt into the

transmission when topping-up.

13 Add the fluid a little at a time, and keep

checking the level as previously described

until it is correct. The difference between the

upper and lower part of the shaded sector is

approximately 0.9 litre.

All models

14 The need for regular topping-up of the

transmission fluid indicates a leak, which

should be found and rectified without delay.

15 The condition of the fluid should also be

checked along with the level. If the fluid at the

end of the dipstick is black or a dark reddish-

brown colour, or if it has a burned smell, the

fluid should be changed. If you are in doubt

about the condition of the fluid, purchase

some new fluid, and compare the two for

colour and smell.

Every 24 000 miles 1•23

31.12 Add the specified automatic

transmission fluid through the dipstick

tube, using a clean funnel

31.10 Automatic transmission fluid level

dipstick (1), Lower (2) and upper (3) shaded

sector and dipstick tube (4)

31.6 Automatic transmission fluid level

dipstick (1) and level markings on

4-cylinder engine models

1

1380 Rover 800 Series Remake

Every 24 000 miles or 2 years, whichever occurs first

32 Timing belt condition and

tension check

4

1 The manufacturers have increased the

service interval for checking the timing belt

condition and tension on certain engines, due

to the introduction of automatic tensioners

and improvements in timing belt construction

and manufacture. However, the conse-

quences of timing belt failure can be very

expensive in terms of possible engine damage

and it is still worthwhile to check the belt at

the shorter intervals given in this schedule.

The procedures vary considerably according

to engine type and model year, and reference

should be made to the appropriate Part of

Chapter 2 for full information.

33 Positive Crankcase

Ventilation (PCV) system

check

1

1 The function of the crankcase ventilation

system is to reduce the emission of unburned

hydrocarbons from the crankcase, and to

minimise the formation of oil sludge. By

ensuring that a depression is created in the

crankcase under most operating conditions,

particularly at idle, and by positively inducing

fresh air into the system, the oil vapours and

“blow-by” gases collected in the crankcase

are drawn from the crankcase, through the air

cleaner or oil separator, into the inlet tract, to

be burned by the engine during normal

combustion.

2 On four cylinder engines, the main

components of the system are an oil

separator, diverter valve and associated

hoses. Checking of the system consists of a

simple visual check of the component hoses

and their connections.

3 On V6 engines the crankcase ventilation

system main components are a PCV valve,

located in the breathing chamber of the front

camshaft cover, and the hoses that connect

to the internal channels in the inlet manifold.

As with 4-cylinder engines, checking is limited

to merely a visual hose condition check.

Accurate checking of the PCV valve should be

entrusted to a dealer.

4 Check that all components of the system

are securely fastened, correctly routed (with

no kinks or sharp bends to restrict flow) and in

sound condition; renew any worn or damaged

components.

Loading...

Loading...