3 Disable the ignition system by

disconnecting the LT wiring connectors from

the ignition coil. Refer to Chapter 5 for further

information.

4 Fit a compression tester to the No 1

cylinder spark plug hole - the type of tester

which screws into the plug thread is to be

preferred.

5 Arrange for an assistant to hold the

accelerator pedal fully depressed to the floor

while at the same time cranking the engine

over several times on the starter motor.

Observe the compression gauge reading. The

compression will build up fairly quickly in a

healthy engine. Low compression on the first

stroke, followed by gradually increasing

pressure on successive strokes indicates

worn piston rings. A low compression on the

first stroke which does not rise on successive

strokes, indicates leaking valves or a blown

head gasket (a cracked cylinder head could

also be the cause). Deposits on the underside

of the valve heads can also cause low

compression. Record the highest gauge

reading obtained, then repeat the procedure

for the remaining cylinders.

6 Due to the variety of testers available, and

the fluctuation in starter motor speed when

cranking the engine, different readings are

often obtained when carrying out the

compression test. However, the most

important factor is that the compression

pressures are uniform in all cylinders, and that

is what this test is mainly concerned with.

7 Add some engine oil (about three squirts

from a plunger type oil can) to each cylinder

through the spark plug holes and repeat the

test.

8 If the compression increases after the oil is

added it is indicative that the piston rings are

definitely worn. If the compression does not

increase significantly, the leakage is occurring

at the valves or the head gasket. Leakage

past the valves may be caused by burned

valve seats and/or faces or warped, cracked

or bent valves.

9 If two adjacent cylinders have equally low

compressions, it is most likely that the head

gasket has blown between them. The

appearance of coolant in the combustion

chambers or crankcase would verify this

condition.

10 If one cylinder is about 20 percent lower

than the other, and the engine has a rough

idle, a worn lobe on the camshaft could be the

cause.

11 On completion of the checks, refit the

spark plugs and reconnect the LT wiring at

the ignition coil.

4 Camshaft covers -

removal and refitting

1

“M” series engines

Removal

1 Detach the breather hose from the rear of

the inlet camshaft cover.

2 On cars with multi-point fuel injection,

release the plastic covers then undo the two

bolts securing the plenum chamber support

brackets to the plenum chamber.

3 Undo the two bolts and lift off the spark

plug cover from the centre of the cylinder

head. Note that the spark plug HT lead

grommet engages with the end of the cover,

and on certain models, an accelerator cable

support bracket is also retained by the right-

hand cover bolt.

4 Undo the ten bolts securing each camshaft

cover to its respective camshaft housing, and

lift off the two covers (see illustrations).

5 Withdraw the baffle plates, taking care not

to damage the sealing edges on both sides of

the plates (see illustration).

Refitting

6 Refitting is a reversal of removal. Renew the

baffle plates if their sealing edges are

damaged. Tighten the bolts to the specified

torque.

“T” series engines

Removal

7 Detach the breather hoses from the side

and rear of the inlet camshaft cover.

8 Undo the two bolts securing the plenum

chamber support brackets to the plenum

chamber.

9 Undo the four screws and lift off the spark

plug cover between the two camshaft covers.

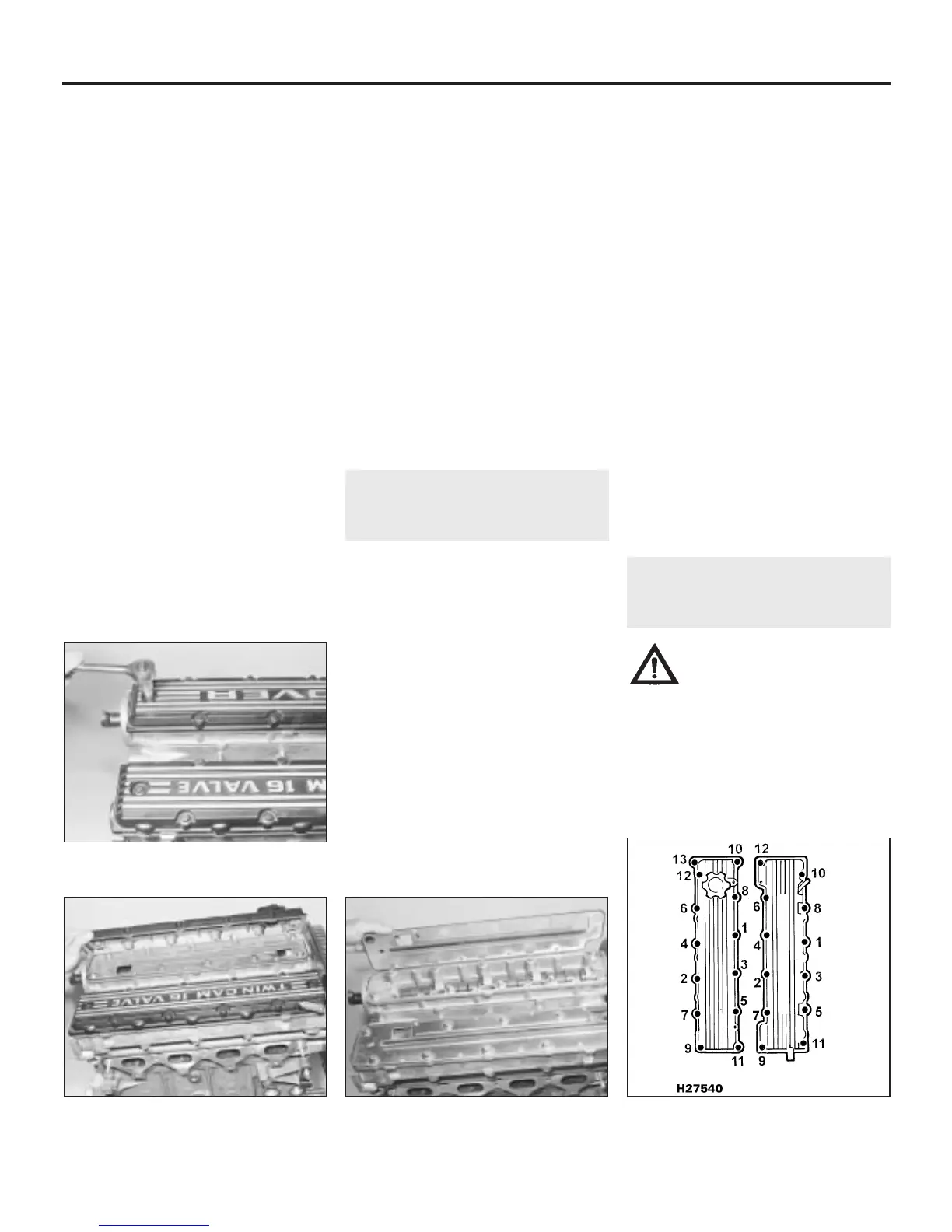

10 Working from the centre outwards

slacken then remove the ten bolts (inlet

camshaft cover), or 12 bolts (exhaust

camshaft cover) and lift off the two covers.

11 Withdraw the baffle plates, taking care not

to damage the sealing edges on both sides of

the plates.

Refitting

12 Refitting is a reversal of removal. Renew

the baffle plates if their sealing edges are

damaged. Tighten the cover bolts to the

specified torque in the sequence shown (see

illustration).

5 Inlet manifold -

removal and refitting

1

Warning: Petrol is extremely

flammable, so take extra

precautions when disconnecting

any part of the fuel system.

Don’t smoke, or allow naked flames or

bare light bulbs in or near the work area.

Don’t work in a garage where a natural

gas appliance (such as a clothes dryer or

water heater) is installed. If you spill petrol

on your skin, rinse it off immediately. Have

a fire extinguisher rated for petrol fires

handy, and know how to use it.

2A•4 4-cylinder engine – in-car engine repair procedures

4.12 Camshaft cover tightening sequence

for “T” series engines

4.5 Remove the baffle plates over the

camshafts

4.4b . . . and remove the covers

4.4a Undo the camshaft cover retaining

bolts . . .

1380 Rover 800 Series Remake

Loading...

Loading...