9 Timing belt tensioner and

sprockets - removal,

inspection and refitting

4

Tensioner

Removal

1 Remove the timing belt as described in

Sections 7, or 8, according to engine type.

2 On the “M” series engine, the tensioner will

have been removed together with the timing

belt; proceed to paragraph 6.

3 On the “T” series engine, slacken the

tensioner retaining bolt and allow the

tensioner to move fully under the action of the

spring.

4 Unhook the tensioner spring from the

anchorage stud.

5 Remove the tensioner retaining bolt, lift off

the tensioner and remove the spring.

Inspection

6 Spin the tensioner, and ensure that there is

no roughness or harshness in the bearing.

Also check that the endfloat is not excessive

and there is no sign of free play. Check the

surface of the tensioner for any signs of

roughness, nicks or scoring which may

damage the timing belt. Renew the tensioner

if worn.

7 On “T” series engines, measure the free

length of the tensioner spring. If the free

length is greater than that specified, renew the

spring.

Refitting

8 Refitting is a reversal of removal.

Camshaft sprockets

Removal

9 Remove the timing belt as described in

Sections 7, or 8, according to engine type.

10 Undo the retaining bolt securing each

sprocket to its respective camshaft. To

prevent the sprockets turning as the bolts are

undone, either insert a large screwdriver

through one of the sprocket holes and engage

it with one of the backplate bolts behind, or

make up a holding tool from scrap metal,

which is of a scissor shape, with a bolts at

each end to engage with the holes in the

sprocket.

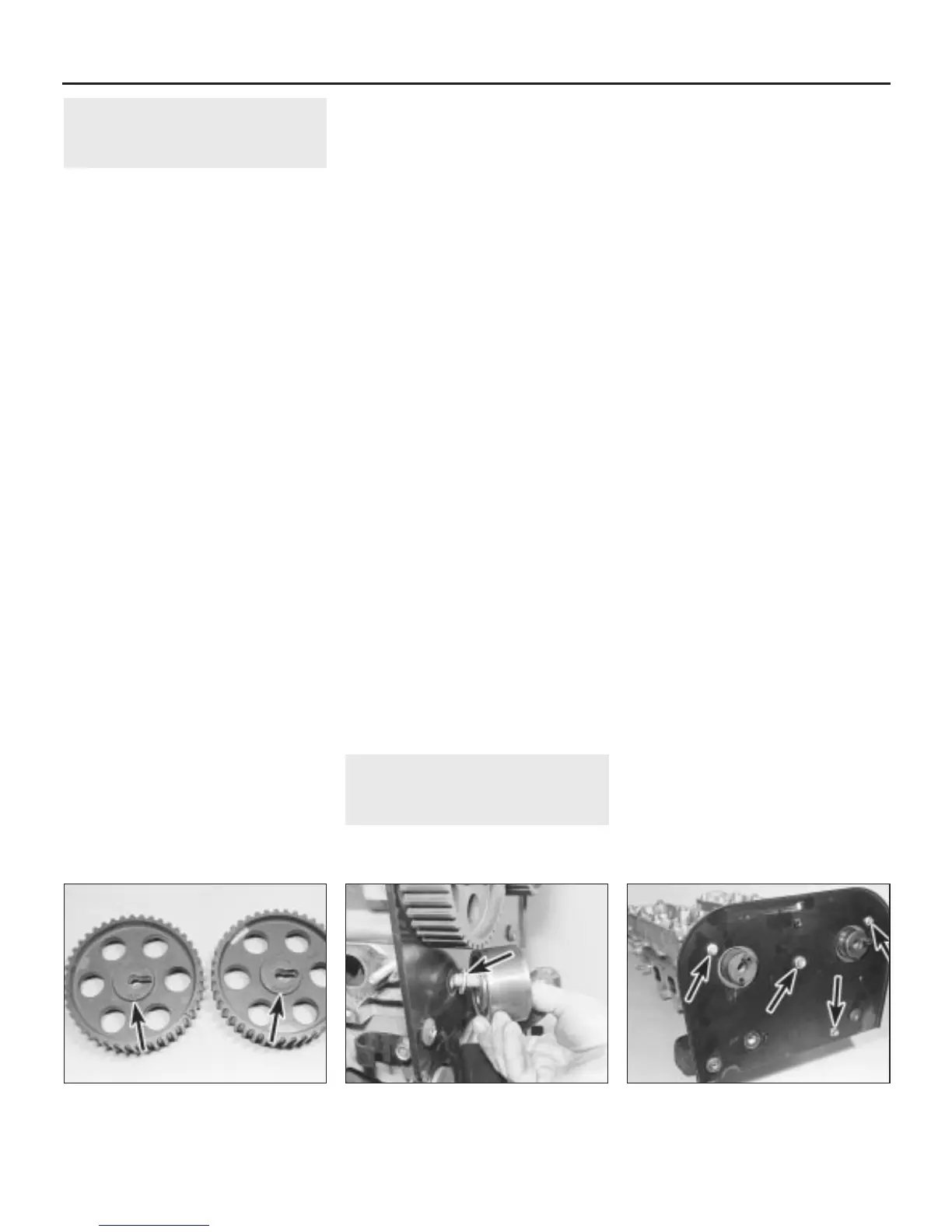

11 Withdraw the two sprockets from the

camshafts, noting that they are not identical,

and should be marked INLET (or IN) and

EXHAUST on their front faces to avoid

confusion. If no marks are visible, make your

own to identify each sprocket (see

illustration).

Inspection

12 Check the condition of the sprockets,

inspecting carefully for any wear grooves,

pitting or scoring around the teeth, or any

wear ridges which might cause damage to the

timing belt. Make sure that the dowels are not

worn and are not a loose fit in the camshaft or

sprocket holes.

Refitting

13 Refitting is a reversal of removal. Ensure

that the sprockets are fitted to their correct

camshafts and tighten the retaining bolt to the

specified torque.

Crankshaft sprocket

Removal

14 Remove the timing belt as described in

Sections 7, or 8, according to engine type.

15 Slide the sprocket off the front of the

crankshaft (“T” series engines).

Inspection

16 Check the condition of the sprocket,

inspecting carefully for any wear grooves,

pitting or scoring around the teeth, or any

wear ridges which might cause damage to the

timing belt. Examine the Woodruff key and its

groove and make sure it is a tight fit.

Refitting

17 Refitting is a reversal of removal.

10 Camshaft oil seals -

renewal

4

Note: The use of an oil seal extractor which

screws into the seal inside circumference is

preferable for this operation. These are

available at most accessory shops and can

often be hired from tool hire outlets. In the

absence of this type of tool, an alternative (but

less satisfactory) method of removal is

described in the following procedure.

Front oil seals

1 Remove the camshaft sprockets as

described in the previous Section.

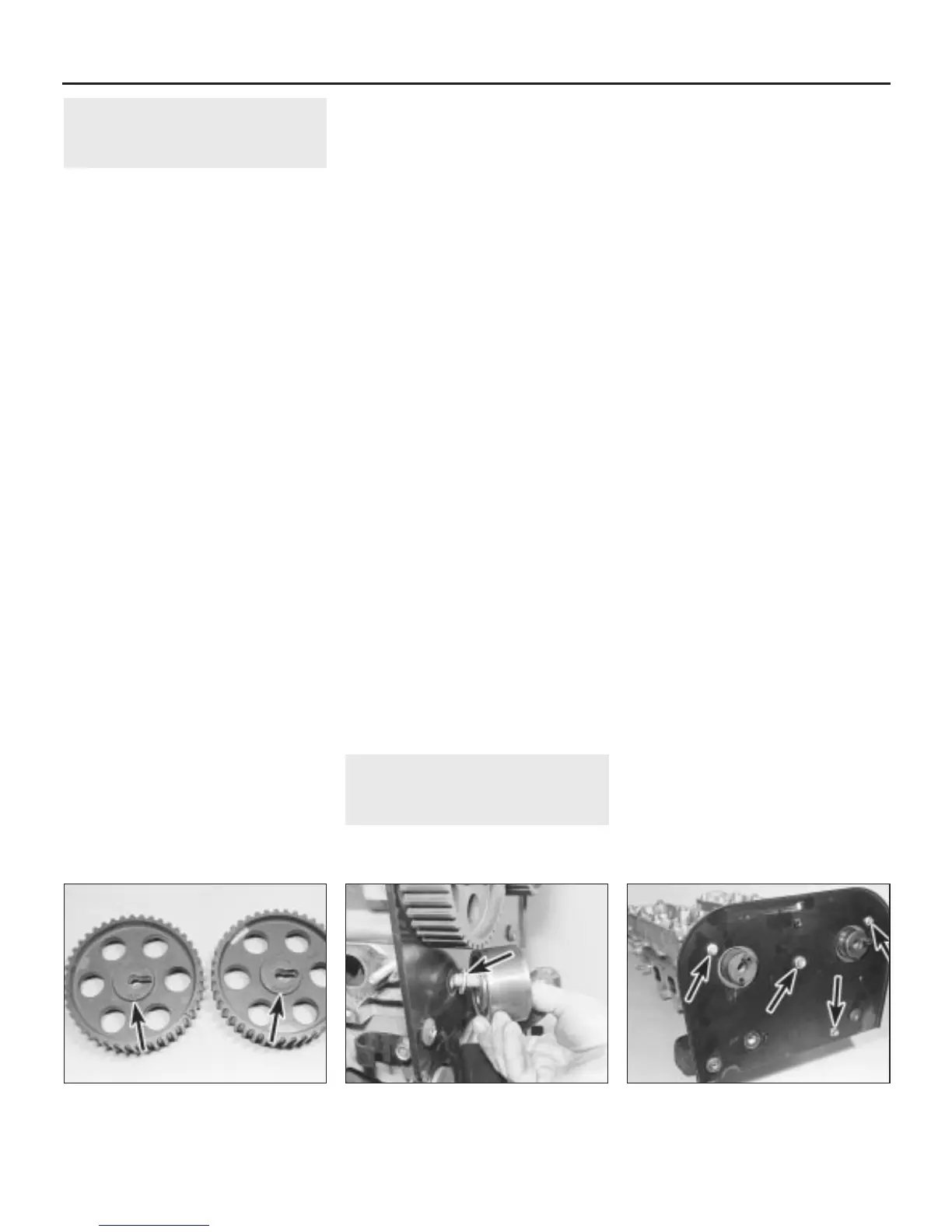

2 On early “M” series engines undo the

retaining bolt using an Allen key, and remove

the timing belt idler pulley. Recover the spacer

behind the pulley (see illustration).

3 Undo the bolts and remove the backplate

from the cylinder head (see illustration).

4 The oil seals are now accessible for

removal. Punch or drill two small holes

opposite each other in the oil seal.

Screw a self-tapping screw into each hole and

pull on the screws with pliers to extract the

seal.

5 Check that the housing is clean before

fitting the new seal. Lubricate the lips of the

seal and the running faces of the camshaft

with clean engine oil, then carefully locate the

seal over the camshaft and drive it squarely

into position using a tube or a socket. Take

great care not to turn over the lips of the seal

as it is being fitted. An alternative method of

fitting is to draw it squarely into position using

the sprocket bolt and a distance piece.

6 With the seal fully inserted in its housing,

refit the components removed for access then

refit the camshaft sprockets as described in

the previous Section.

Rear oil seals

Exhaust camshaft oil seal

7 Refer to the relevant Part of Chapter 4 and

remove the air cleaner assembly and intake

trunking components as necessary for

access.

8 Undo the two retaining bolts, withdraw the

distributor cap, and place it to one side.

9 Undo the retaining Allen screw, and remove

the distributor rotor arm.

10 Undo the two screws and remove the

2A•10 4-cylinder engine – in-car engine repair procedures

10.3 Undo the bolts (arrowed) and remove

the backplate

10.2 Remove the timing belt idler pulley

and recover the spacer (arrowed)

9.11 The camshaft sprockets are marked

INLET (or IN) and EXHAUST on their front

faces (arrowed)

1380 Rover 800 Series Remake

Loading...

Loading...