the crankshaft one turn clockwise, then one

turn anti-clockwise. It must be emphasised

that this is only an approximate setting, and

the tension should be checked by a dealer,

using the Rover tension gauge, at the earliest

opportunity.

52 The remainder of refitting is a reversal of

removal.

8 Timing belt (“T” series) -

removal, refitting and

adjustment

4

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

2 Slacken the right-hand front wheel nuts,

jack up the front of the car and support it on

axle stands. Remove the roadwheel.

3 Undo the three bolts and remove the

access panel under the wheelarch.

4 Refer to Chapter 1 and remove the auxiliary

drivebelt.

5 Position a jack and interposed block of

wood under the sump, and just take the

weight of the engine.

6 Undo the bolts securing the power steering

pipe support brackets, and move the pipes

slightly to gain access to the right-hand

engine mounting.

7 Undo the engine mounting through-bolt,

and recover the special nut. Note that the

forked end of the nut plate locates over a stud

on the body bracket.

8 Undo the two bolts securing the engine

mounting to its mounting bracket, and remove

the mounting.

9 Raise the engine slightly, then undo the five

bolts and lift off the timing belt upper cover

(see illustration).

10 Undo the remaining five bolts and remove

the timing belt centre cover.

11 Using a socket or spanner on the

crankshaft pulley, turn the crankshaft in an

anti-clockwise direction until the timing

notches on the camshaft sprockets are facing

each other and aligned horizontally. Insert a

dowel rod or drill through the hole in the

transmission adaptor plate, near to the lower

edge of the cylinder block on the front-facing

side of the engine (see illustration 7.12). The

dowel or drill will then engage with a

corresponding hole in the flywheel. If the

dowel won’t engage, turn the crankshaft

through 180º and try again.

12 With the dowel rod engaged and the

camshaft notches aligned, the crankshaft is at

90º BTDC, with No 1 piston on its

compression stroke. Temporarily remove the

dowel rod.

13 Refer to Chapter 5, and remove the starter

motor.

14 Using a socket and long handle, slacken

the crankshaft pulley centre retaining bolt.

Lock the flywheel ring gear, through the

starter motor aperture, using a large

screwdriver or similar tool to prevent the

crankshaft rotating as the pulley bolt is

undone. This operation will probably have

moved the timing marks on the camshafts out

of alignment, so re-align them, and fit the

crankshaft dowel rod as described previously.

15 Remove the centre retaining bolt from the

crankshaft pulley, then unscrew the four

additional pulley bolts and remove the pulley.

16 Undo the three bolts and remove the

timing belt bottom cover.

17 Slacken the timing belt tensioner centre

bolt, move the tensioner away from the belt as

far as it will go, then re-tighten the tensioner

bolt.

18 Slip the belt off the sprockets, and

remove it from the engine.

19 If the timing belt is to be re-used, mark its

running direction with an arrow in chalk, and

store it on its edge while it is off the engine.

20 Check the tensioner and sprockets as

described in Section 9.

Refitting and adjustment

21 Before refitting the belt, check that the

crankshaft is still at the 90º BTDC position

(dowel rod engaged) and that the timing

marks on the two sprockets are still aligned.

22 Engage the timing belt with the teeth of

the crankshaft sprocket, and then pull the belt

vertically upright on its straight, right-hand

run. Keep it taut, and engage it over the

exhaust camshaft sprocket, then the inlet

camshaft sprocket.

23 Check that none of the sprockets have

moved, then feed the belt around the

tensioner.

24 Refit the timing belt bottom cover.

25 Remove the dowel rod from the

crankshaft.

26 Refit the crankshaft pulley and secure

with the centre bolt and four additional bolts,

tightened to the specified torque. Hold the

crankshaft using the same procedure as for

removal to tighten the centre bolt.

27 Slacken the timing belt tensioner retaining

bolt slightly and allow the tensioner to

automatically tension the belt.

28 Using a torque wrench applied to the inlet

camshaft sprocket retaining bolt, apply a load

of 40 Nm, in an anti-clockwise direction, to

take up all the slack in the timing belt. Hold

this load, and tighten the tensioner retaining

bolt to the specified torque.

29 The remainder of refitting is a reversal of

removal.

4-cylinder engine – in-car engine repair procedures 2A•9

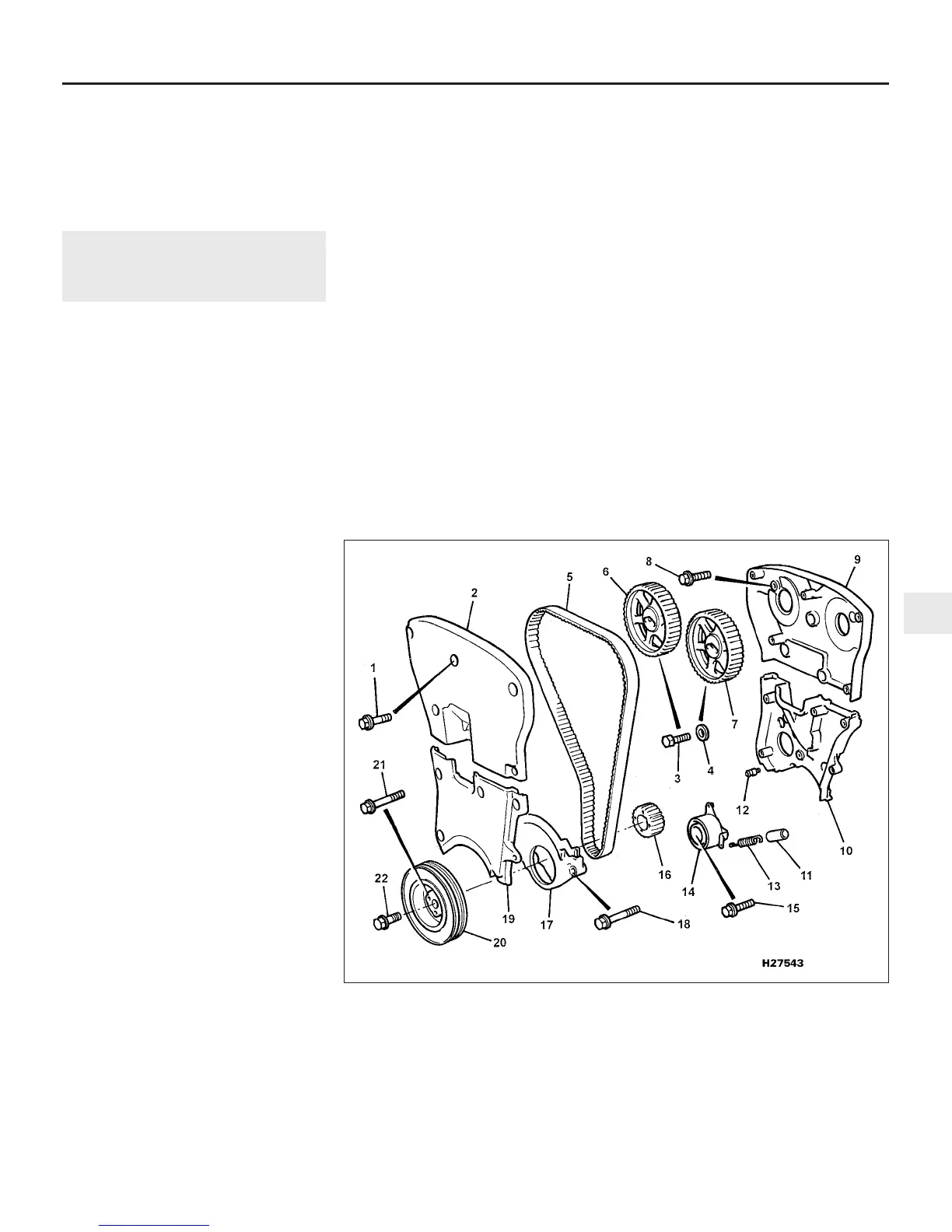

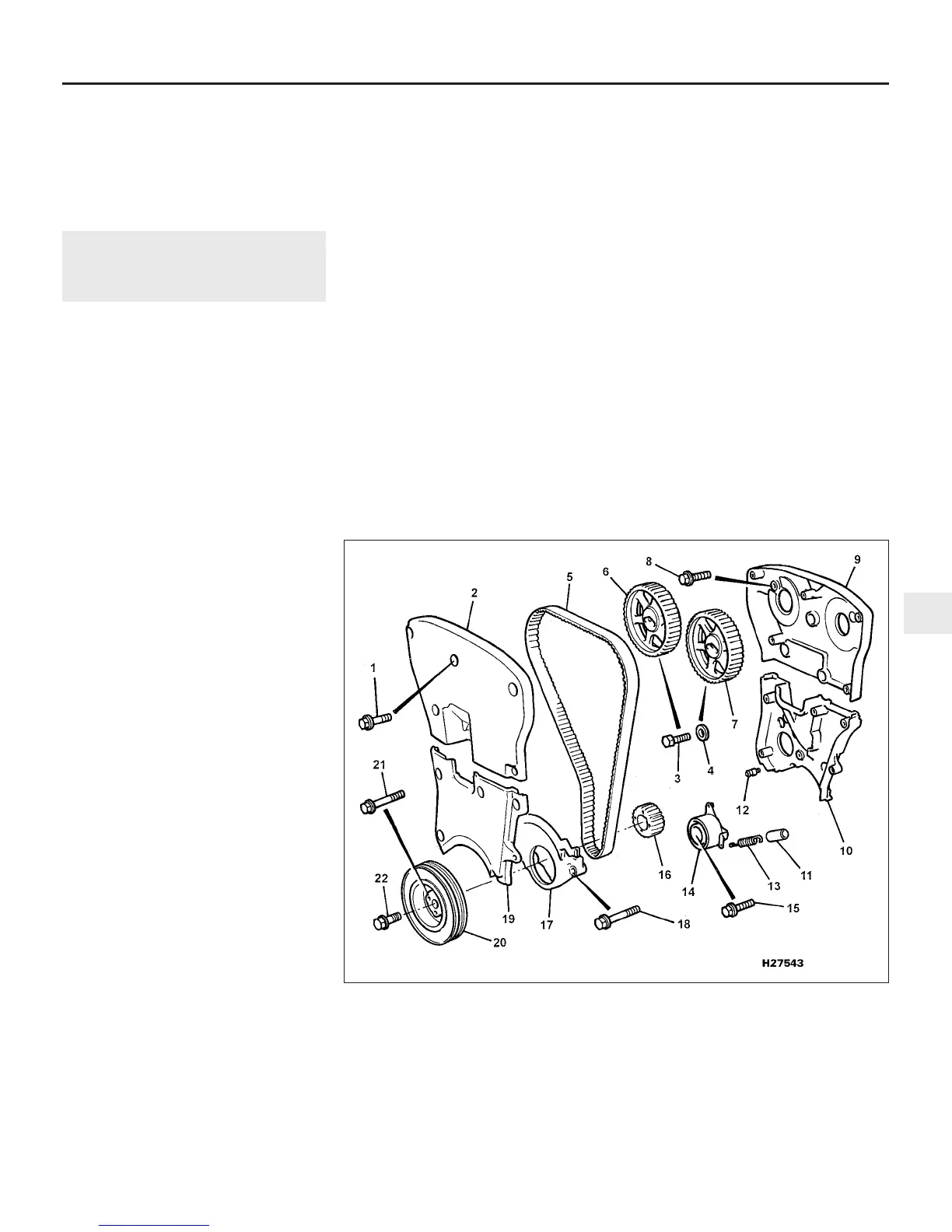

8.9 Timing belt components as fitted to “T” series engines

1 Upper cover bolt

2 Upper cover

3 Camshaft sprocket bolt

4 Washer

5 Timing belt

6 Inlet camshaft sprocket

7 Exhaust camshaft sprocket

8 Backplate bolt

9 Upper backplate

10 Lower backplate

11 Spring sleeve

12 Anchorage bolt

13 Tensioner spring

14 Timing belt tensioner

15 Tensioner bolt

16 Crankshaft sprocket

17 Bottom cover

18 Bottom cover bolt

19 Centre cover

20 Crankshaft pulley

21 Pulley-to-sprocket bolts

22 Pulley centre bolt

2A

1380 Rover 800 Series Remake

Loading...

Loading...