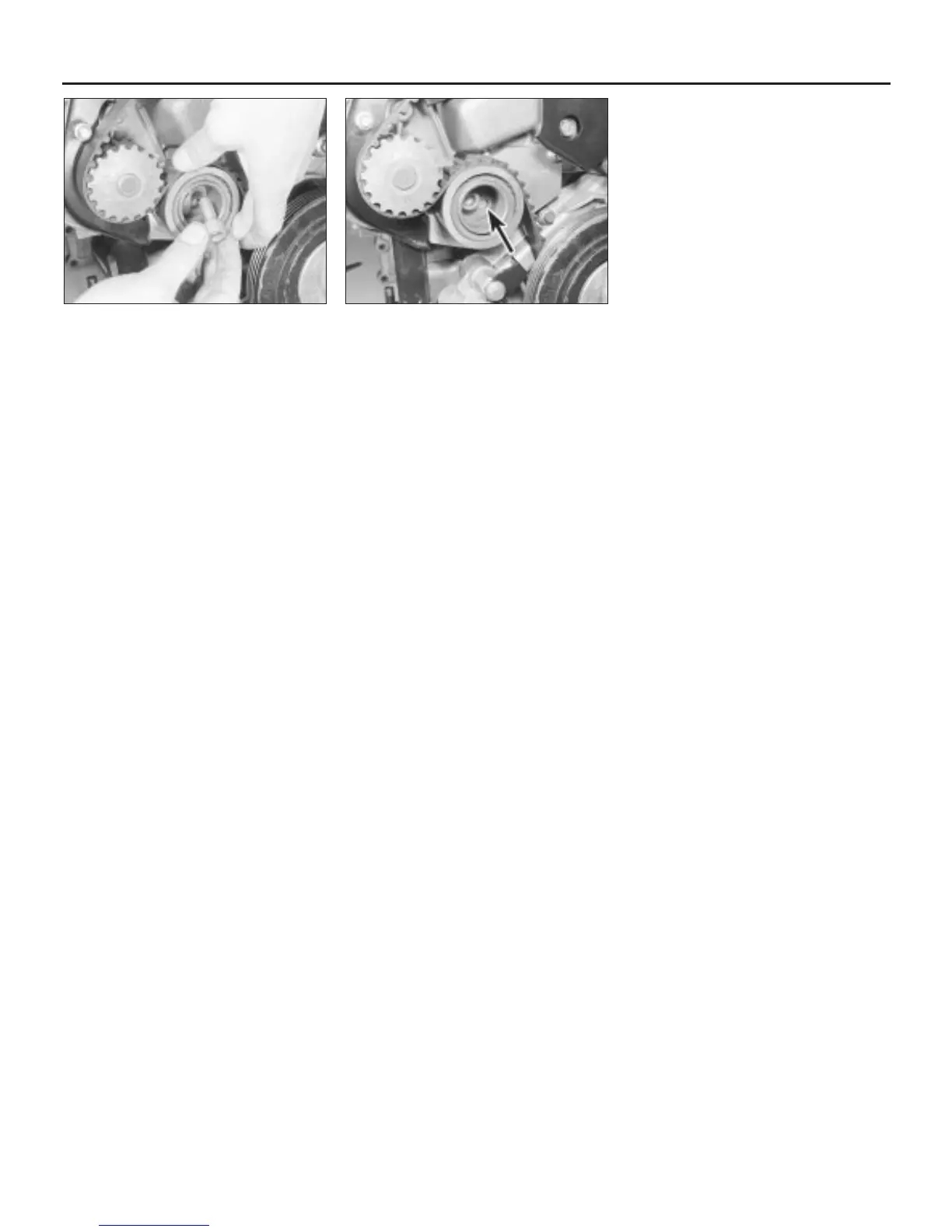

14 Using an Allen key, undo the timing belt

tensioner retaining bolt, and remove the

tensioner (see illustration).

15 Slip the belt off the sprockets, and

remove it from the engine.

16 If the timing belt is to be re-used, mark its

running direction with an arrow in chalk, and

store it on its edge while it is off the engine.

17 Check the belt for any sign of cracks or

splits, particularly around the roots of the

teeth. Renew the belt if wear is obvious, if

there are signs of oil contamination, or if the

belt has exceeded its service interval (see

Chapter 1). Also renew the sprockets if they

show any signs of wear or chipping of the

teeth.

18 Check the tensioner and sprockets as

described in Section 9.

19 Before refitting, check that the crankshaft

is still at the 90º BTDC position, and that the

timing marks on the two sprockets are still

aligned.

Refitting and adjustment

20 Engage the timing belt with the teeth of

the crankshaft sprocket, and then pull the belt

vertically upright on its straight, right-hand

run. Keep it taut, and engage it over the

exhaust camshaft sprocket, then the inlet

camshaft sprocket.

21 Check that none of the sprockets have

moved, then feed the belt around the idler

pulley and engage it with the teeth of the

water pump sprocket.

22 Fit the timing belt tensioner and secure

with the retaining bolt, tightened finger-tight

only at this stage.

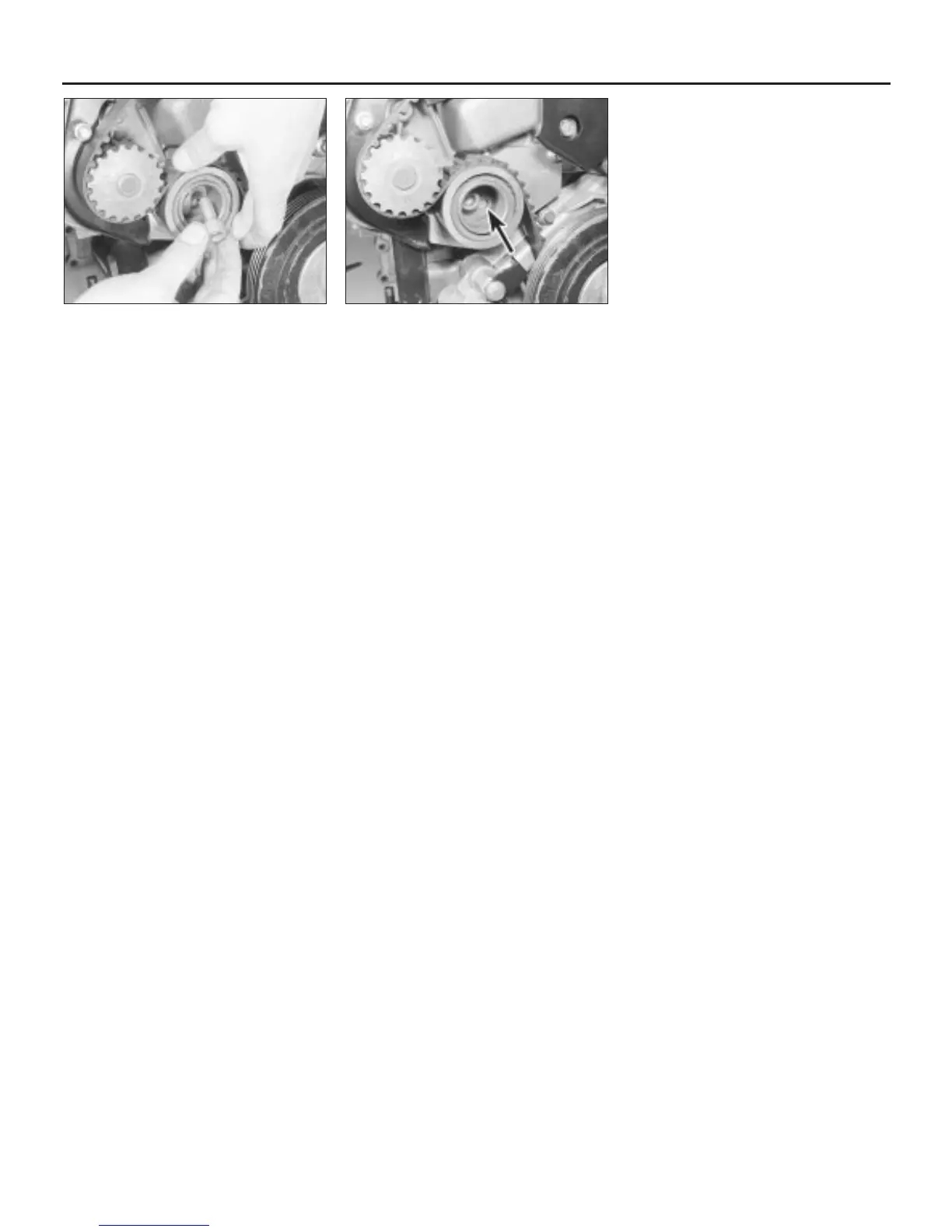

23 Engage an Allen key with the hexagonal

adjusting hole in the tensioner, and turn the

tensioner body until there is moderate tension

on the belt (see illustration). Hold the

tensioner in this position, and tighten the

retaining bolt.

24 Remove the locking pin (if used) from the

transmission adaptor plate, and turn the

crankshaft one complete turn clockwise,

followed by one complete turn anti-clockwise,

and re-align the timing marks.

25 Check that it is just possible to deflect the

belt, using moderate hand pressure, by

19.0 mm at a point midway between the

crankshaft and exhaust camshaft sprockets.

Re-adjust the tension if necessary by

slackening the tensioner retaining bolt, and

repositioning the tensioner body with the Allen

key. Recheck the tension again after turning

the crankshaft one turn clockwise, then one

turn anti-clockwise. It must be emphasised

that this is only an approximate setting, and

the tension should be checked by a dealer,

using the Rover tension gauge, at the earliest

opportunity.

26 Refit the timing belt bottom cover, turn the

crankshaft to align the pulley timing mark with

the edge of the bottom cover, and make a

final check that the camshaft sprocket timing

marks are still aligned.

27 Refit the timing belt upper and lower

covers.

28 Refit the engine mounting to its bracket,

lower the engine and secure the mounting to

the body with the through-bolt and special

nut.

29 Refer to Chapter 1 and refit the auxiliary

drivebelt.

30 Refit the power steering pipe support

brackets, the wheelarch access panel, and

the roadwheel.

31 Lower the car to the ground, tighten the

wheel nuts fully, and reconnect the battery.

Later “M” series engines

Removal

32 Proceed as described in paragraphs 1 to

9 above.

33 Undo the four bolts and remove the timing

belt centre cover.

34 Using a socket or spanner on the

crankshaft pulley, turn the crankshaft in an anti-

clockwise direction until the notches on the

camshaft sprockets are facing each other and

aligned horizontally. Insert a dowel rod or drill

through the hole in the transmission adaptor

plate, near to the lower edge of the cylinder

block on the front-facing side of the engine

(see illustration 7.12). The dowel or drill will

then engage with a corresponding hole in the

flywheel. If the dowel won’t engage, turn the

crankshaft through 180º and try again. With the

dowel rod engaged and the camshaft notches

aligned, the crankshaft is at 90º BTDC, with

No 1 piston on its compression stroke.

Temporarily remove the dowel rod.

35 Refer to Chapter 5, and remove the starter

motor.

36 Using a socket and long handle, slacken

the crankshaft pulley centre retaining bolt.

Lock the flywheel ring gear, through the

starter motor aperture, using a large

screwdriver or similar tool to prevent the

crankshaft rotating as the pulley bolt is

undone. This operation will probably have

moved the timing marks on the camshafts out

of alignment, so re-align them, and fit the

crankshaft dowel rod as described previously.

37 Remove the centre retaining bolt from the

crankshaft pulley, then unscrew the four

additional pulley bolts and remove the pulley.

38 Undo the bolts and remove the timing belt

bottom cover.

39 Using an Allen key, undo the timing belt

tensioner retaining bolt, and remove the ten-

sioner.

40 Slip the belt off the sprockets, and

remove it from the engine.

41 Check the timing belt, sprockets and

tensioner as described in paragraphs 16 to

18.

42 Before refitting, check that the crankshaft

is still at the 90º BTDC position, and that the

timing marks on the two sprockets are still

aligned.

Refitting and adjustment

43 Engage the timing belt with the teeth of

the crankshaft sprocket, and then pull the belt

vertically upright on its straight, right-hand

run. Keep it taut, and engage it over the

exhaust camshaft sprocket, then the inlet

camshaft sprocket.

44 Check that none of the sprockets have

moved, then feed the belt around the idler

pulley and engage it with the teeth of the

water pump sprocket.

45 Fit the timing belt tensioner and secure

with the retaining bolt, tightened finger-tight

only at this stage.

46 Refit the timing belt bottom cover.

47 Remove the dowel rod from the

crankshaft.

48 Refit the crankshaft pulley and secure

with the centre bolt and four additional bolts,

tightened to the specified torque. Hold the

crankshaft using the same procedure as for

removal to tighten the centre bolt.

49 Engage an Allen key with the hexagonal

adjusting hole in the tensioner, and turn the

tensioner body until there is moderate tension

on the belt. Hold the tensioner in this position,

and tighten the retaining bolt.

50 Turn the crankshaft one complete turn

clockwise, followed by one complete turn

anti-clockwise, and re-align the timing marks.

51 Check that it is just possible to deflect the

belt, using moderate hand pressure, by

19.0 mm at a point midway between the

crankshaft and exhaust camshaft sprockets.

Re-adjust the tension if necessary by

slackening the tensioner retaining bolt, and

repositioning the tensioner body with the Allen

key. Recheck the tension again after turning

2A•8 4-cylinder engine – in-car engine repair procedures

7.23 Tensioner hexagonal adjusting hole

(arrowed)

7.14 Removing the timing belt tensioner

1380 Rover 800 Series Remake

Loading...

Loading...