Inspection

17 Clean and inspect the various

components removed for signs of excessive

wear.

18 Examine the camshaft bearing journals

and lobes for damage or wear. If evident, a

new camshaft must be fitted or one that has

been renovated by a company specialising in

exchange components.

19 The camshaft bearing bore diameters in

the cylinder head should be measured and

checked against the tolerances specified. A

gauge will be required for this but if not

available, check for excessive movement

between the camshaft journals and the

bearings. Alternatively, the Plastigage

method, described in Part C of this Chapter,

for main and big-end bearing running

clearance checks, can be used. If the

bearings are found to be unacceptably worn,

either a new camshaft or a new cylinder head

is required as the bearings are machined

directly in the head.

20 It is seldom that the hydraulic tappets are

badly worn in the cylinder head bores but

again, if the tappets are scored, or the bores

are found to be worn beyond an acceptable

level, either the tappet(s) or the complete

cylinder head must be renewed.

21 If the contact surface of the cam lobes

show signs of depression or grooving, note

that they cannot be renovated by grinding as

the hardened surface will be removed and the

overall length of the tappet(s) will be reduced.

The self-adjustment point of the tappet will be

exceeded as a result, so that the valve

adjustment will be affected and they will then

be noisy in operation. Therefore, renewal

of the camshaft is the only remedy in this

case.

Refitting

22 Remove all traces of sealant from the

camshaft housing retaining bolt holes in the

cylinder head, using an M8 x 1.25 mm tap.

Alternatively, use one of the old bolts with two

file grooves cut into its threads. Also ensure

that there is no oil remaining at the bottom of

the bolt holes.

23 Thoroughly lubricate the tappet bores in

the cylinder head, and refit the tappets in their

original positions.

24 Lubricate the camshaft journals and

lobes, then place the camshafts in position.

Temporarily place the sprockets over the

ends of the camshafts, and position the

camshafts in the cylinder head so that the

sprocket timing marks are horizontal and

towards each other.

25 Lubricate the sealing lips of the new oil

seals, carefully ease them over the camshaft

journals, and position them against the

shoulder in the cylinder head (see illustration).

26 Apply a thin bead of Loctite sealant 574 to

the camshaft housing-to-cylinder head mating

face, then place both housings in position on

the cylinder head (see illustration).

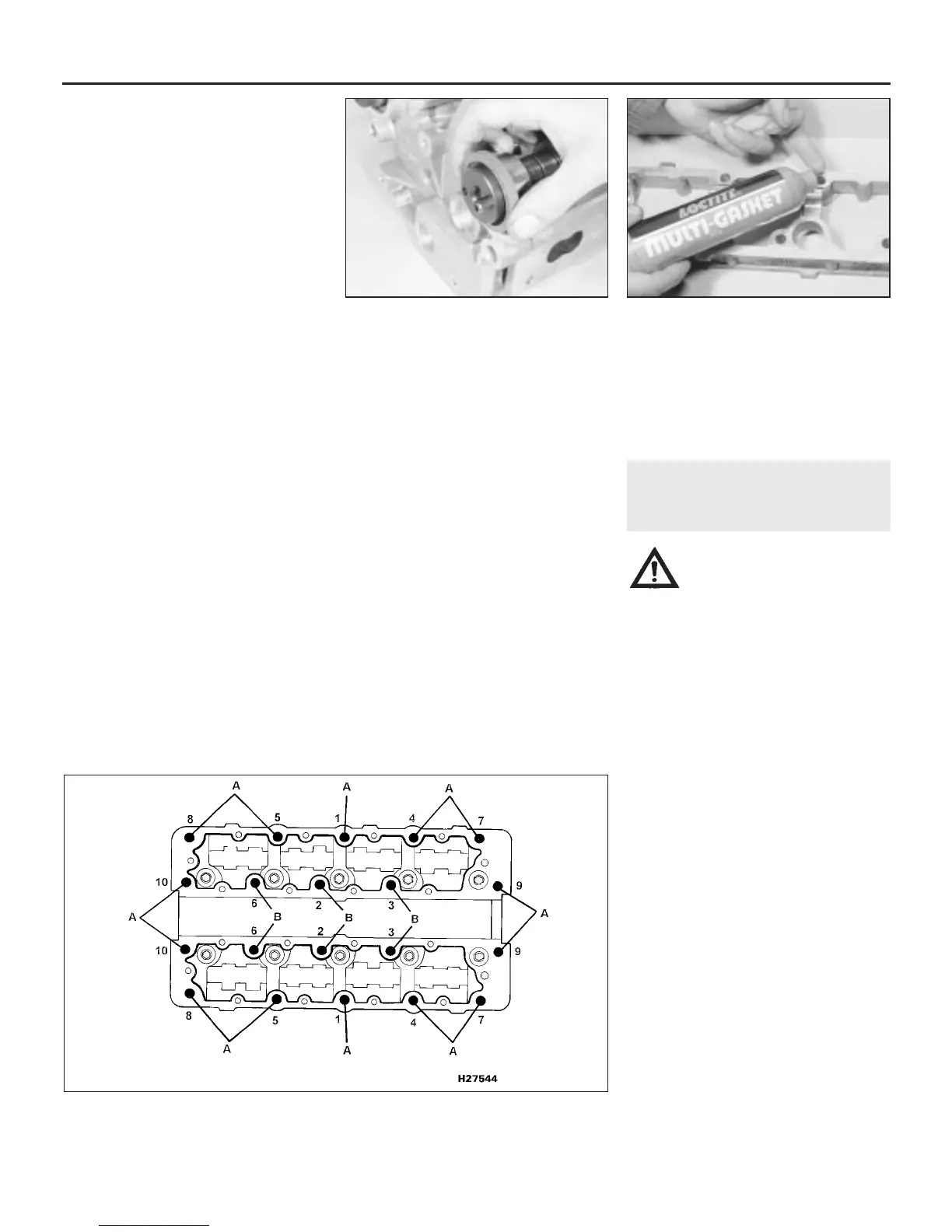

27 Fit new housing retaining bolts (3 plain

bolts and 7 patch bolts for each housing) and

tighten them in the order shown (see

illustration). Note the locations of the two

types of bolt.

28 The remainder of refitting is a reversal of

removal. When the engine is finally started, be

prepared for a considerable rattle from the

tappets until they completely fill with oil. This

may take a few minutes, and will be more

pronounced if any of the tappets have been

renewed.

12 Cylinder head -

removal and refitting

4

Warning: Petrol is extremely

flammable, so take extra

precautions when disconnecting

any part of the fuel system.

Don’t smoke, or allow naked flames or

bare light bulbs in or near the work area.

Don’t work in a garage where a natural

gas appliance (such as a clothes dryer or

water heater) is installed. If you spill petrol

on your skin, rinse it off immediately. Have

a fire extinguisher rated for petrol fires

handy, and know how to use it.

Single-point fuel injection

engines

Removal

1 Drain the cooling system as described in

Chapter 1.

2 Remove the air cleaner, air box and intake

trunking as described in Chapter 4A.

3 Remove the timing belt as described in

Section 7 or 8, according to engine type.

4 Remove the camshaft covers as described

in Section 4.

5 Undo the nuts and separate the exhaust

front pipe from the manifold flange. Recover

the gasket.

6 Slacken the clips and disconnect the

radiator top hose, and the expansion tank

hose at the thermostat housing.

7 Disconnect the wiring multiplug at the

coolant temperature sensor.

8 Undo the brake servo vacuum hose banjo

union bolt on the right-hand side of the inlet

manifold, and recover the two copper

washers.

9 Slacken the clip and disconnect the heater

hose at the inlet manifold, behind the brake

servo vacuum hose.

2A•12 4-cylinder engine – in-car engine repair procedures

11.26 Apply sealant to the camshaft

housing mating face

11.25 Fitting the camshaft oil seals

1380 Rover 800 Series Remake

11.27 Camshaft housing retaining bolt identification and tightening sequence

A Patch bolt locations B Plain bolt locations

Loading...

Loading...