10 Undo the bolt securing the stay bar to the

inlet manifold, below the heater hose.

11 Slacken the clips and disconnect the

heater bypass hose at the thermostat

housing.

12 Slacken the clip and disconnect the

heater hose at the other end of the bypass

pipe.

13 Undo the bolts securing the bypass pipe

to the exhaust manifold, cylinder head and

main coolant pipe, release the clips securing

the wiring harness, and remove the bypass

pipe from the engine (see illustration).

14 Slacken the clip and disconnect the

coolant hose at the left-hand end of the inlet

manifold.

15 Disconnect the vacuum hoses from the

inlet manifold, adjacent to the coolant hose.

Mark the location of each hose as it is

disconnected.

16 Undo the bolt securing the support

bracket to the inlet manifold, below the

vacuum hoses.

17 At the rear of the engine below the inlet

manifold, release the wire clip and detach the

breather hose from the top of the oil

separator. Also detach the hose from the

crankcase ventilation system diverter valve

(see illustration).

18 Disconnect the two wires to the inlet

manifold heater temperature sensor, on the

underside of the manifold, and the single lead

to the manifold heater at the wiring connector.

19 Slacken the accelerator cable locknuts,

and unscrew the lower locknut off the outer

cable end. Open the throttle at the throttle

cam, slip the cable end out of the cam slot,

and remove the cable from the support

bracket. Release the cable from the camshaft

cover support bracket, and place it clear of

the engine.

20 On automatic transmission models,

disconnect the kickdown cable, using the

same procedure as for the accelerator cable.

21 Disconnect the wiring multiplugs at the

idle speed stepper motor, the fuel injector,

and the throttle potentiometer. Move the

wiring harness clear of the cylinder head.

22 Place absorbent rags around the fuel filter

outlet union banjo bolt on the left-hand side of

the filter, then slowly unscrew the bolt to

release the fuel system pressure. Remove the

bolt and recover the two copper washers after

the pressure has been released. Tape over the

filter orifice and banjo union to prevent fuel

loss and dirt ingress.

23 Disconnect the fuel return hose at the

pipe below the fuel filter.

24 Remove the dipstick from the dipstick

tube.

25 On cars fitted with a rear-mounted power

steering pump, extract the circlip from the end

of the power steering pump drivebelt tension

adjuster bolt. Slide the adjuster rearwards,

and undo all the accessible bolts securing the

adjuster bracket to the cylinder head. Now

move the adjuster the other way, and undo

the remaining bolts, then remove the adjuster

assembly complete.

26 Progressively slacken all the cylinder head

retaining bolts, in the reverse sequence to that

shown (see illustration 12.32c). Remove the

bolts when all have been slackened.

27 With the help of an assistant, lift the

cylinder head, complete with manifolds, off

the engine. If the head is stuck, it can be

carefully levered up using a large screwdriver

between the cylinder block and the protruding

cylinder head flanges. Do not insert the

screwdriver under the head-to-block mating

face. Place the head on blocks on the bench

to protect the valves.

28 Remove the cylinder head gasket from the

block.

29 Prior to refitting, ensure that the cylinder

block and head mating faces are thoroughly

clean and dry, with all traces of old gasket

removed. Clean the threads of the retaining

bolts, and remove any oil, water and thread

sealer from the bolt holes.

Refitting

30 Locate a new gasket over the dowels on

the cylinder block (see illustration).

31 Check that the crankshaft is still

positioned at the 90º BTDC position, and that

the timing marks on the camshaft sprockets

are aligned.

32 Lower the cylinder head assembly onto

the gasket, and refit the retaining bolts.

Working in the sequence shown, tighten the

retaining bolts in stages, to the specified

torque and angle settings given in the Specifi-

cations (see illustrations).

33 The remainder of refitting is a reversal of

4-cylinder engine – in-car engine repair procedures 2A•13

12.30 Locate a new cylinder head gasket

over the dowels

12.17 Detach the hose from the diverter

valve (arrowed)

12.13 Release the wiring harness clips

from the bypass pipe

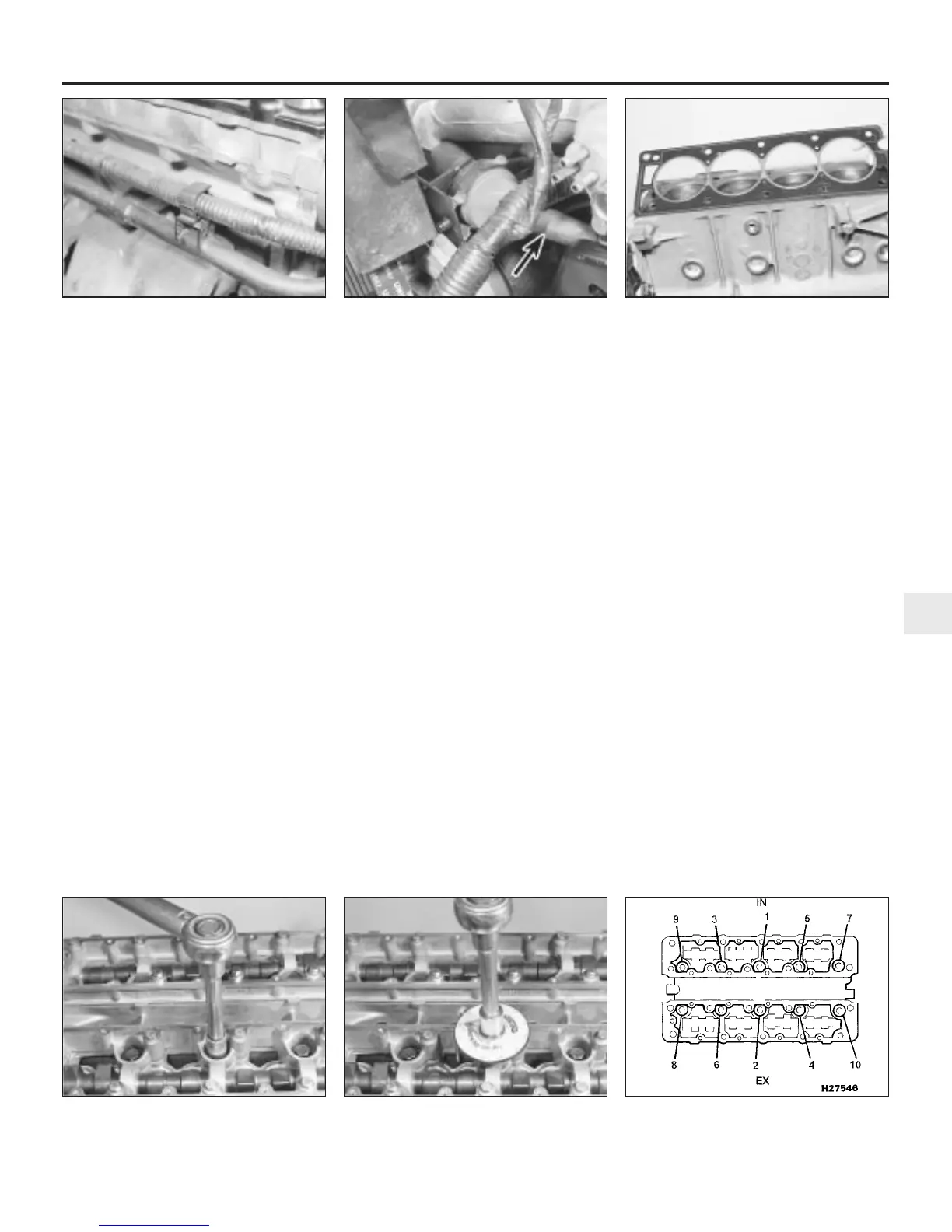

12.32b . . . then angle-tighten the bolts to

the specified angular setting

12.32a Tighten the cylinder head bolts to

the specified torque . . .

2A

1380 Rover 800 Series Remake

12.32c Cylinder head bolt tightening

sequence

Loading...

Loading...