removal but refer to the relevant Sections

and Chapters for adjustment details as

necessary.

Multi-point fuel injection

engines

Removal

34 Carry out the operations described in

Paragraphs 1 to 8.

35 On turbocharged engines remove the

exhaust manifold as described in the relevant

part of Chapter 4.

36 Slacken the clip and disconnect the

heater hose at the other end of the bypass

pipe.

37 Undo the bolts securing the bypass pipe

to the exhaust manifold, cylinder head and

main coolant pipe, and remove the bypass

pipe.

38 Slacken the clips and disconnect the two

coolant hoses from the underside of the

throttle housing.

39 At the rear of the engine, disconnect the

wiring multiplugs and leads at the crankshaft

sensor, knock sensor, oil pressure switch and

oil pressure transducer.

40 Disconnect the main engine wiring loom

multiplug(s) on the right-hand side valance as

necessary, to enable part of the loom to be

removed with the cylinder head.

41 Check that all the wiring likely to impede

removal of the cylinder head and its ancillaries

has been disconnected, and the harness

moved clear. It may be necessary to

disconnect additional wiring, depending on

options or additional equipment fitted.

42 Disconnect the breather hoses from the

oil separator.

43 Open the throttle fully by hand, and slip

the accelerator inner cable end out of the slot

on the throttle lever.

44 Slacken the outer cable locknuts, and

unscrew the outer locknut, nearest to the

cable end, fully. Remove the washer and

rubber bush, then withdraw the cable from the

support bracket.

45 On automatic transmission models,

disconnect the kickdown cable, using the

same procedure as for the accelerator cable.

46 Place absorbent rags around the fuel filter

outlet union banjo bolt on the left-hand side of

the filter, then slowly unscrew the bleed screw

in the centre of the bolt to release the fuel

system pressure. Tighten the bleed screw

when the pressure has been released. Undo

the outlet union banjo bolt, and recover the

two copper washers. Tape over the filter

orifice, and banjo union to prevent fuel loss

and dirt entry.

47 Unscrew the union nut and disconnect the

fuel return hose at the fuel pressure regulator,

on the left-hand side of the inlet manifold.

48 Remove the dipstick from the dipstick

tube.

49 On cars fitted with a rear-mounted power

steering pump, extract the circlip from the end

of the power steering pump drivebelt tension

adjuster bolt. Slide the adjuster rearwards,

and undo all the accessible bolts securing the

adjuster bracket to the cylinder head. Now

move the adjuster the other way, and undo

the remaining bolts, then remove the adjuster

assembly complete.

50 Progressively slacken all the cylinder head

retaining bolts, in the reverse sequence to that

shown (see illustration 12.32c). Remove the

bolts when all have been slackened.

51 With the help of an assistant, lift the

cylinder head, complete with manifolds, off

the engine. If the head is stuck, it can be

carefully levered up using a large screwdriver

between the cylinder block and the protruding

cylinder head flanges. Do not insert the

screwdriver under the head-to-block mating

face. Place the head on blocks on the bench

to protect the valves.

52 Remove the cylinder head gasket from the

block.

53 Prior to refitting, ensure that the cylinder

block and head mating faces are thoroughly

clean and dry, with all traces of old gasket

removed. Clean the threads of the retaining

bolts, and remove any oil, water and thread

sealer from the bolt holes.

Refitting

54 Locate a new gasket over the dowels on

the cylinder block.

55 Check that the crankshaft is still

positioned at the 90º BTDC position, and that

the timing marks on the camshaft sprockets

are aligned.

56 Lower the cylinder head assembly onto

the gasket, and refit the retaining bolts.

Working in the sequence shown, tighten the

retaining bolts in stages, to the specified

torque and angle settings given in the Specifi-

cations (see illustration 12.32c).

57 The remainder of refitting is a reversal of

removal but refer to the relevant Sections

and Chapters for adjustment details as

necessary.

13 Sump -

removal and refitting

1

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

2 Apply the handbrake, jack up the front of

the car and support it on axle stands.

3 Drain the engine oil as described in Chapter

1.

4 Remove the exhaust front section with

reference to the appropriate Part of Chap-

ter 4.

5 Undo the bolts securing the longitudinal

support member to the underbody

beneath the engine, and remove the

member.

6 Disconnect the crankcase breather

hose from the pipe stub on the side of the

sump.

7 Where applicable, release the turbocharger

oil return hose from the sump.

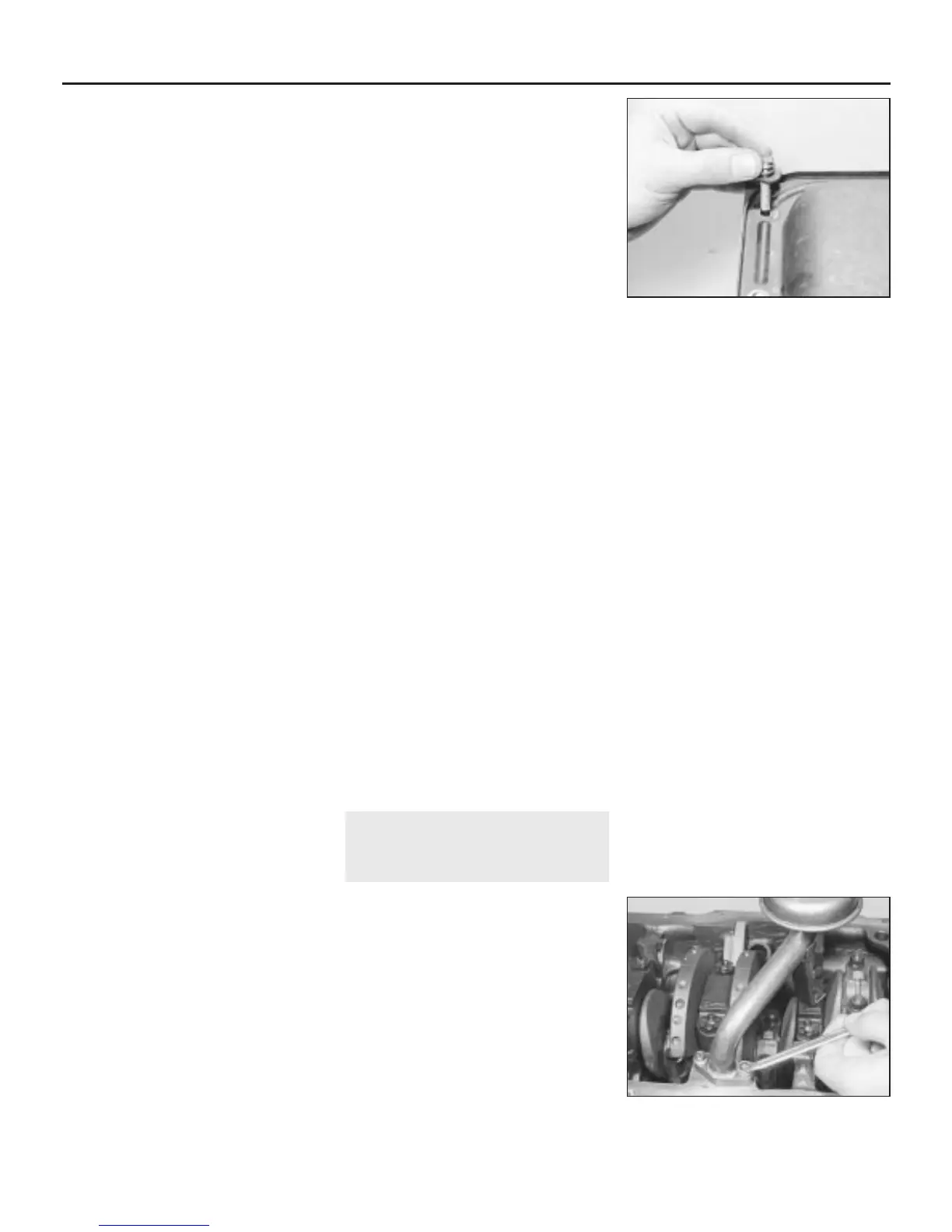

8 Slacken, then remove, the sump retaining

bolts, noting that the corner bolt on the drain

plug side at the flywheel end is longer than the

rest, and has a flat washer and elongated

washer in addition to the normal spring

washer (see illustration).

9 Withdraw the sump from the crankcase,

tapping it from side to side with a hide or

plastic mallet if it is stuck. Recover the sump

gasket.

10 If the oil pick-up tube and strainer are to

be removed, undo the two bolts securing the

tube flange to the crankcase, and the single

bolt securing the support bracket to the main

bearing cap (see illustration).

11 Slide the support bracket from under the

crankcase breather oil return pipe, and

remove the pick-up pipe and tube from the

crankcase. Recover the O-ring from the pick-

up pipe flange.

12 Clean the sump thoroughly, and remove

all traces of old gasket and sealant from the

mating faces of the sump and crankcase.

13 If removed, clean the pick-up pipe, and

the filter gauze in the strainer.

Refitting

14 Place a new O-ring seal on the pick-up

pipe flange, fit the pipe and strainer assembly,

and secure with the retaining bolts,

2A•14 4-cylinder engine – in-car engine repair procedures

13.8 Sump special retaining bolt

location

1380 Rover 800 Series Remake

13.10 Undo the two pick-up pipe-to-

crankcase bolts

Loading...

Loading...