the old ring then splitting it with a chisel. The

new ring must then be heated so that it

expands slightly, and allowed to cool when in

position on the flywheel. As it cools, it

contracts to a smaller diameter than the

flywheel so as to provide a tight interference

fit. The temperatures involved in this operation

are critical to avoid damaging the ring gear,

and the work should be carried out by a Rover

dealer or motor engineering works.

5 The clutch friction surface on the flywheel

should be checked for grooving or cracks, the

latter being caused by overheating. If these

conditions are evident, renewal of the flywheel

is necessary.

6 On manual and automatic transmission

models, check the condition of the reluctor

ring teeth. If any are bent, broken. or in any

way damaged, renew the ring, which is bolted

to the flywheel or driveplate.

Refitting

7 Refitting is a reversal of removal. Tighten

the new bolts to the specified torque,

then bend over the tabs of a new locking

plate.

18 Engine/transmission

mountings -

inspection and renewal

1

Inspection

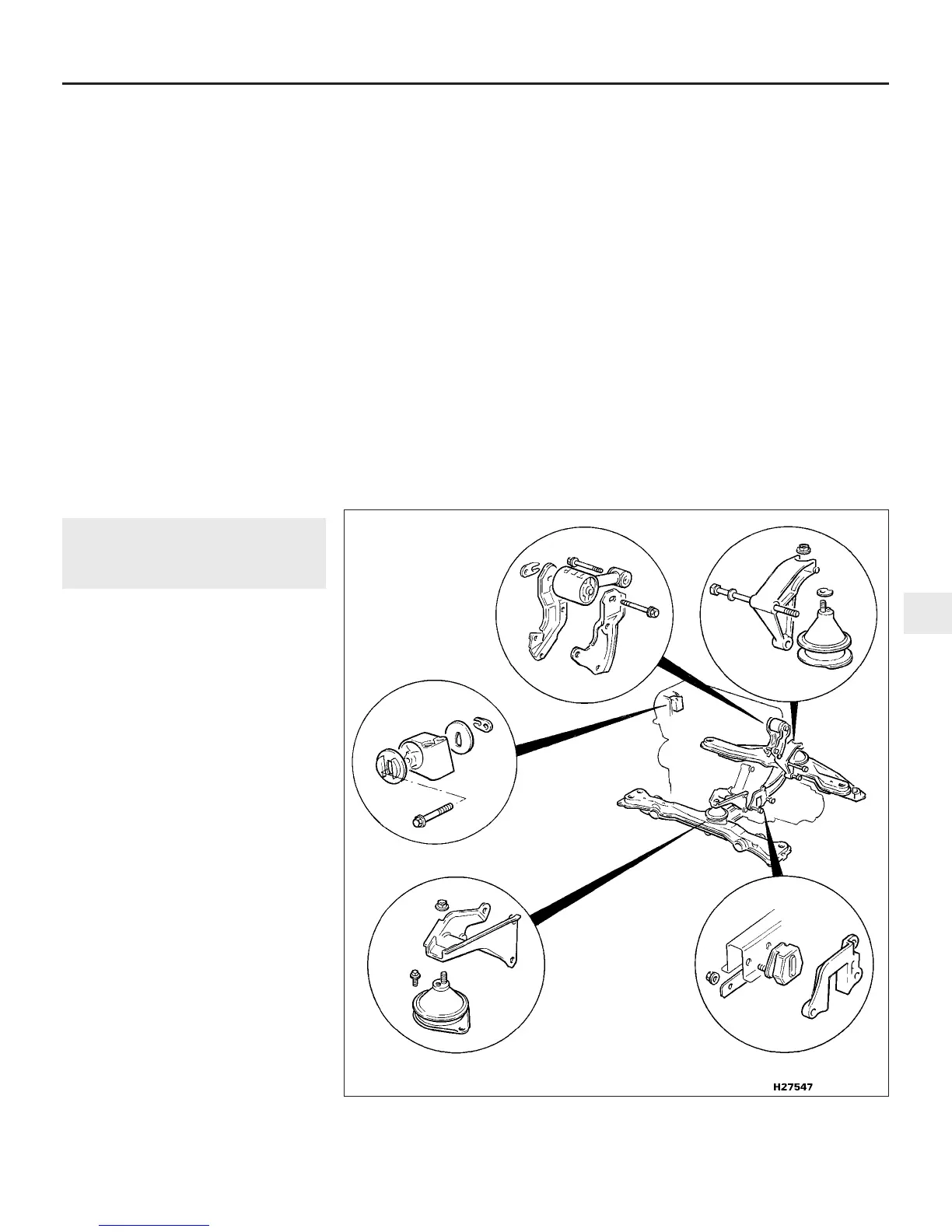

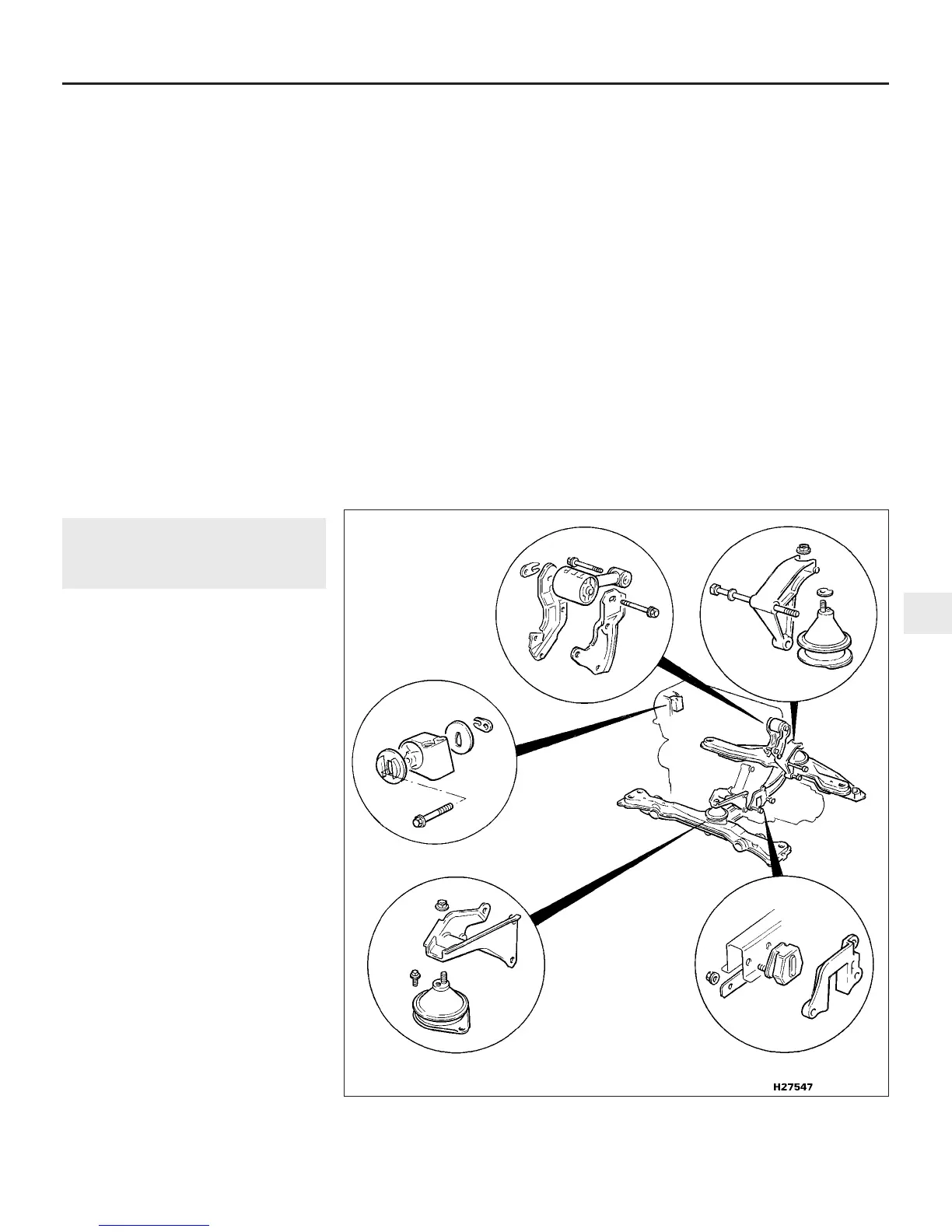

1 The engine/transmission mountings seldom

require attention, but broken or deteriorated

mountings should be renewed immediately, or

the added strain placed on the driveline

components may cause damage or wear (see

illustration).

2 During the check, the engine/transmission

unit must be raised slightly, to remove its

weight from the mountings.

3 Raise the front of the vehicle, and support it

securely on axle stands. Position a jack under

the sump, with a large block of wood between

the jack head and the sump, then carefully

raise the engine/transmission just enough to

take the weight off the mountings.

4 Check the mountings to see if the rubber is

cracked, hardened or separated from the

metal components. Sometimes the rubber will

split right down the centre.

5 Check for relative movement between each

mounting’s brackets and the engine/

transmission or body (use a large screwdriver

or lever to attempt to move the mountings). If

movement is noted, lower the engine and

check-tighten the mounting fasteners.

Renewal

Front mounting

6 Remove the battery as described in

Chapter 5, then undo the retaining bolts and

remove the battery tray.

7 Remove the air cleaner assembly as

described in the relevant part of Chapter 4.

8 Undo the nut securing the mounting to the

engine mounting bracket, and the two bolts

securing the mounting to the front chassis

member.

9 Using a jack and interposed block of wood,

raise the engine slightly until the mounting

stud can be withdrawn from the bracket, then

remove the mounting from the car.

10 Renew the mounting if it shows any sign

of damage, contamination or separation of the

rubber-to-metal bond.

11 Refitting is a reversal of removal, but

ensure that the small peg on the mounting top

face engages with the hole in the bracket, and

tighten the bolts and nut to the specified

torque (Chapter 2, Part C).

Rear mounting

12 Remove the air cleaner assembly and air

intake trunking as described in the relevant

part of Chapter 4.

13 Jack up the front of the car and support it

on axle stands.

14 Undo the bolts and remove the

longitudinal support member from beneath

the engine.

15 Support the engine and transmission

assembly on a jack with interposed block of

wood.

16 Undo and remove all the nuts and bolts

securing the mounting to its mounting bracket

and chassis member, and the mounting

bracket to the engine.

17 Withdraw the mounting bracket from

below, followed by the mounting. If there is a

spacer located between the mounting and

mounting bracket, retain this for refitting with

the existing mounting, but discard it if the

mounting is being renewed.

18 Renew the mounting if it shows any sign

of damage, contamination or separation of the

rubber-to-metal bond.

19 Refitting is a reversal of removal, but

ensure that the small peg on the mounting top

face engages with the hole in the bracket, and

tighten the bolts and nut to the specified

torque (Chapter 2, Part C).

Right-hand mounting

20 Position a jack and interposed block of

wood under the sump, and just take the

weight of the engine.

21 Undo the bolts securing the power

steering pipe support brackets, and move the

4-cylinder engine – in-car engine repair procedures 2A•17

18.1 Engine mounting components (manual transmission shown - automatic

transmission similar)

2A

1380 Rover 800 Series Remake

Loading...

Loading...