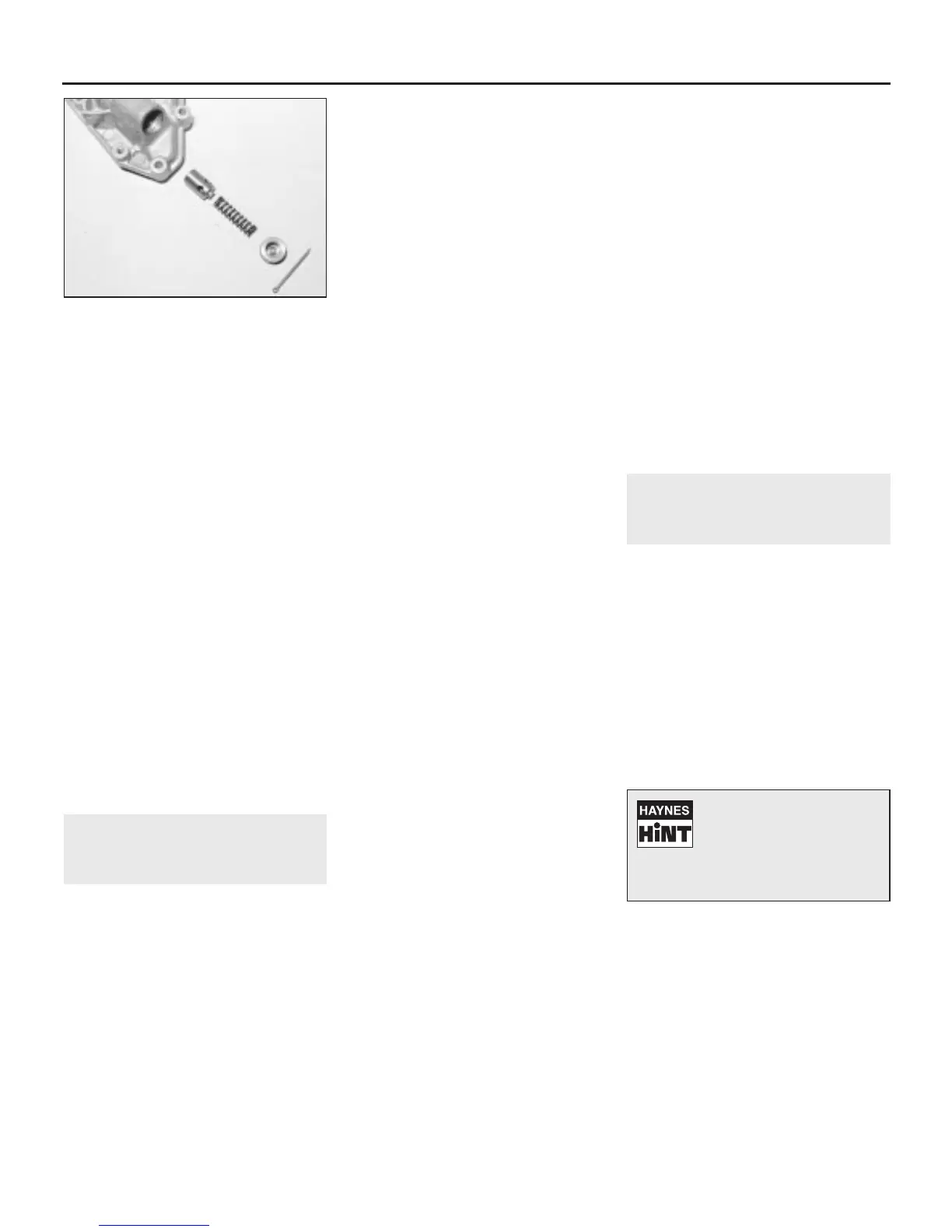

2 To remove the pressure relief valve

components, extract the split pin and

withdraw the plug cap, spring and relief valve

plunger (see illustration).

3 Using a screwdriver, prise out the

crankshaft front oil seal from the oil pump

housing.

Inspection

4 Inspect the condition of the inner and outer

rotors for visual signs of scoring or wear

ridges. Note that the pump internal parts are

not available separately, and if there is any

sign of wear, a complete new oil pump and

housing assembly must be obtained.

5 Check the plunger for scoring or wear

ridges, and renew if necessary. Also renew

the plug cap O-ring if it shows signs of

deterioration.

Reassembly

6 Liberally lubricate the pump rotors to prime

the pump, then refit the pump cover and

secure with the four Torx bolts.

7 Lubricate the relief valve components with

engine oil, then refit the plunger, spring and

plug cap. Secure the cap with a new split pin.

8 Place a new oil seal in position, and

carefully tap it home with the aid of a mallet,

block of wood and the old oil seal.

16 Crankshaft oil seals -

renewal

4

Front oil seal

1 Remove the timing belt as described in

Section 7 or 8, according to engine type.

2 On early “M” series engines, remove the

starter motor as described in Chapter 5. Using

a socket and long handle, slacken the

crankshaft pulley centre retaining bolt. Lock

the flywheel ring gear, through the starter

motor aperture, using a large screwdriver or

similar tool to prevent the crankshaft rotating

as the pulley bolt is undone. Remove the bolt

and withdraw the pulley.

3 On later “M” series engines and all “T”

series engines, withdraw the sprocket from

the crankshaft.

4 Remove the Woodruff key from the slot in

the crankshaft.

5 Punch or drill two small holes opposite

each other in the seal. Screw a self-tapping

screw into each, and pull on the screws with

pliers to extract the seal.

6 Clean the seal housing, and polish off any

burrs or raised edges, which may have

caused the seal to fail in the first place.

7 Lubricate the lips of the new seal with clean

engine oil and carefully locate the seal over

the crankshaft and into the housing.

8 Using a tubular drift which bears on the

hard outer edge of the seal, drive the seal into

the housing until it is flush with the housing

face.

9 Refit the Woodruff key to the crankshaft.

10 On later “M” series engines and all “T”

series engines, refit the sprocket to the

crankshaft.

11 On early “M” series engines, refit the

crankshaft pulley and tighten the retaining bolt

to the specified torque. Prevent the crankshaft

rotating using the same method as used for

removal when tightening the bolt. Refit the

starter motor as described in Chapter 5.

12 Refit the timing belt as described in

Section 7 or 8 as applicable.

Rear oil seal

13 Remove the flywheel/driveplate as

described in Section 17.

“M” series engines

14 Punch or drill two small holes opposite

each other in the seal. Screw a self-tapping

screw into each, and pull on the screws with

pliers to extract the seal.

15 Clean the seal housing, and polish off any

burrs or raised edges, which may have

caused the seal to fail in the first place.

16 Lubricate the lips of the new seal with

clean engine oil and carefully locate the seal

on the end of the crankshaft.

17 Using a tubular drift which bears on the

hard outer edge of the seal, drive the seal into

the housing until it is flush with the housing

face.

18 Clean off any surplus oil then refit the

flywheel/driveplate as described in Sec-

tion 17.

“T” series engines

19 Drain the engine oil as described in

Chapter 1.

20 Slacken all the sump securing bolts in a

progressive sequence, but do not slacken the

three at the timing belt end.

21 Completely remove the two bolts at the

other end, securing the sump to the oil seal

carrier.

22 Undo the five bolts and carefully remove

the oil seal carrier from the cylinder block

dowels and crankshaft. Take great care not to

damage the sump gasket as the carrier is

removed.

23 Note that the oil seal carrier and the oil

seal itself, are supplied as an assembly; the

seal is not available separately.

24 Before refitting, inspect the sump gasket;

if it was damaged in any way during removal it

must be renewed.

25 Clean the end of the crankshaft, and

polish off any burrs or raised edges, which

may have caused the seal to fail in the first

place.

26 Lubricate the lips of the new seal with

clean engine oil and carefully locate the seal

on the end of the crankshaft.

27 Push the oil seal carrier into position over

the locating dowels and refit the retaining

bolts. Progressively tighten the carrier bolts to

the specified torque, starting with the two at

the bottom, then the two in the centre, and

finally the one at the top.

28 Tighten the sump bolts to the specified

torque, in the correct sequence (see Sec-

tion 13).

29 Refit the flywheel/driveplate as described

in Section 17. Refill the engine with oil on

completion of refitting, and check for leaks

around the sump flange when the engine is

run.

17 Flywheel/driveplate -

removal, inspection and

refitting

3

Removal

1 With the engine removed from the car and

separated from the transmission, or with the

transmission removed as described in

Chapter 7, remove the clutch assembly

(manual transmission) as described in Chapter

6.

2 Where fitted, knock back the tabs of the

locking plate, using a screwdriver or small

chisel, and undo the six flywheel/driveplate

retaining bolts. Note that the retaining bolts

are of the encapsulated type, incorporating a

locking compound in their threads, and new

bolts must be obtained for reassembly.

3 Lift off the locking plate, then withdraw the

flywheel/driveplate from the crankshaft. On

automatic transmission models, recover the

spacer from the end of the crankshaft.

Inspection

4 Inspect the starter ring gear on the flywheel

or driveplate for wear or broken teeth. If

evident, the ring gear should be renewed. On

automatic transmission models, the ring gear

is bolted to the driveplate, and renewal is

straightforward. On manual transmission

models however, the ring gear is a shrink fit

on the flywheel, and renewal entails drilling

2A•16 4-cylinder engine – in-car engine repair procedures

15.2 Oil pressure relief valve

components

1380 Rover 800 Series Remake

To prevent the flywheel

turning, lock the ring gear

teeth using a small strip of

angle iron engaged in the

teeth and against the adaptor plate

dowel.

Loading...

Loading...