Wheel changing

155

Changing a wheel

Before raising the vehicle, ensure that all the

precautions listed at the beginning of this

section have been observed.

Also, ensure that the wheel chocks are

correctly positioned (as described previously)

and that the air suspension system is ’locked’

at Standard or High ride height.

WARNING

To prevent any accidental change in the ride

height or automatic levelling of the

suspension, the air suspension system must

remain inhibited during the WHOLE wheel

changing process - to achieve this, ALWAYS

remove the key from the starter switch and

ensure that the tailgate remains open and

the hazard lights are operating throughout.

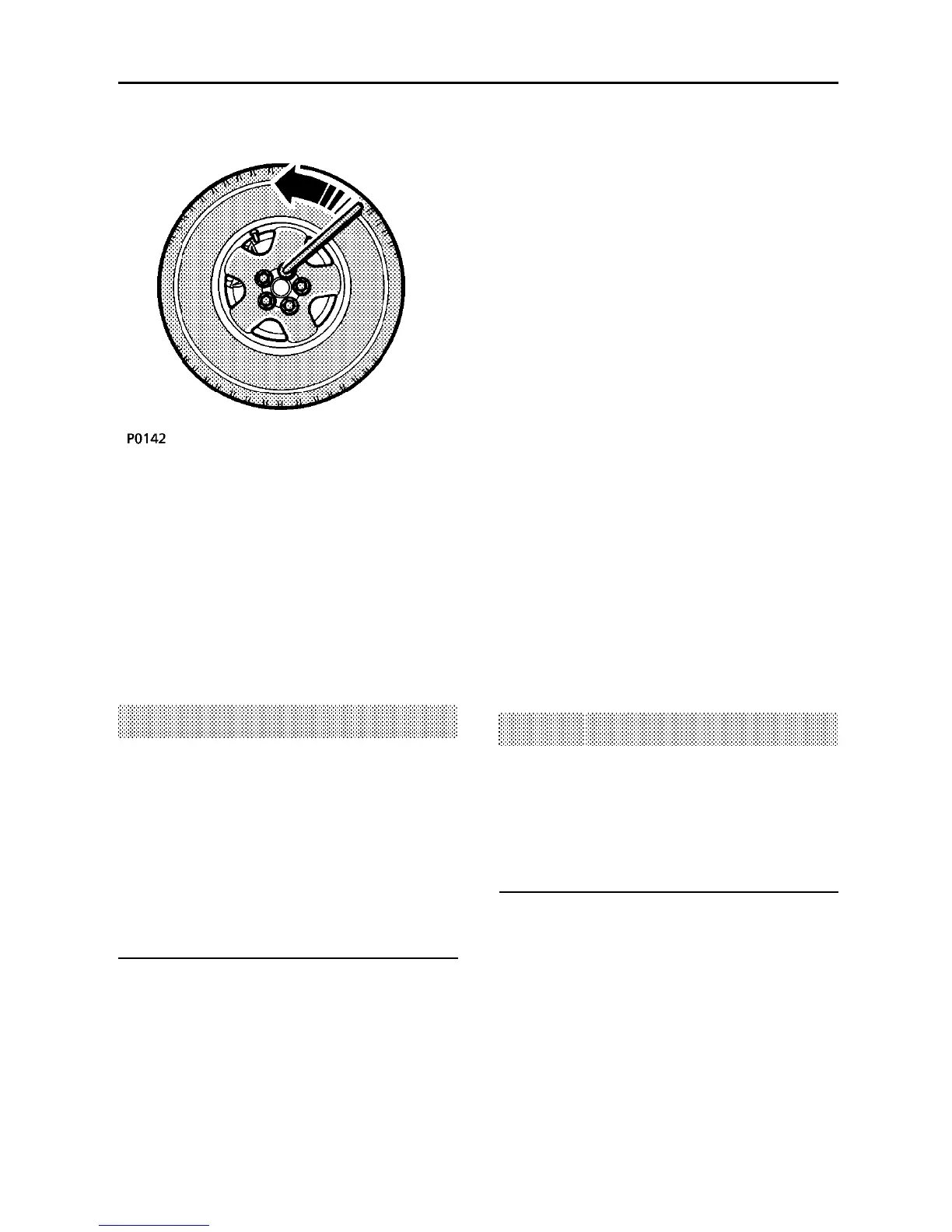

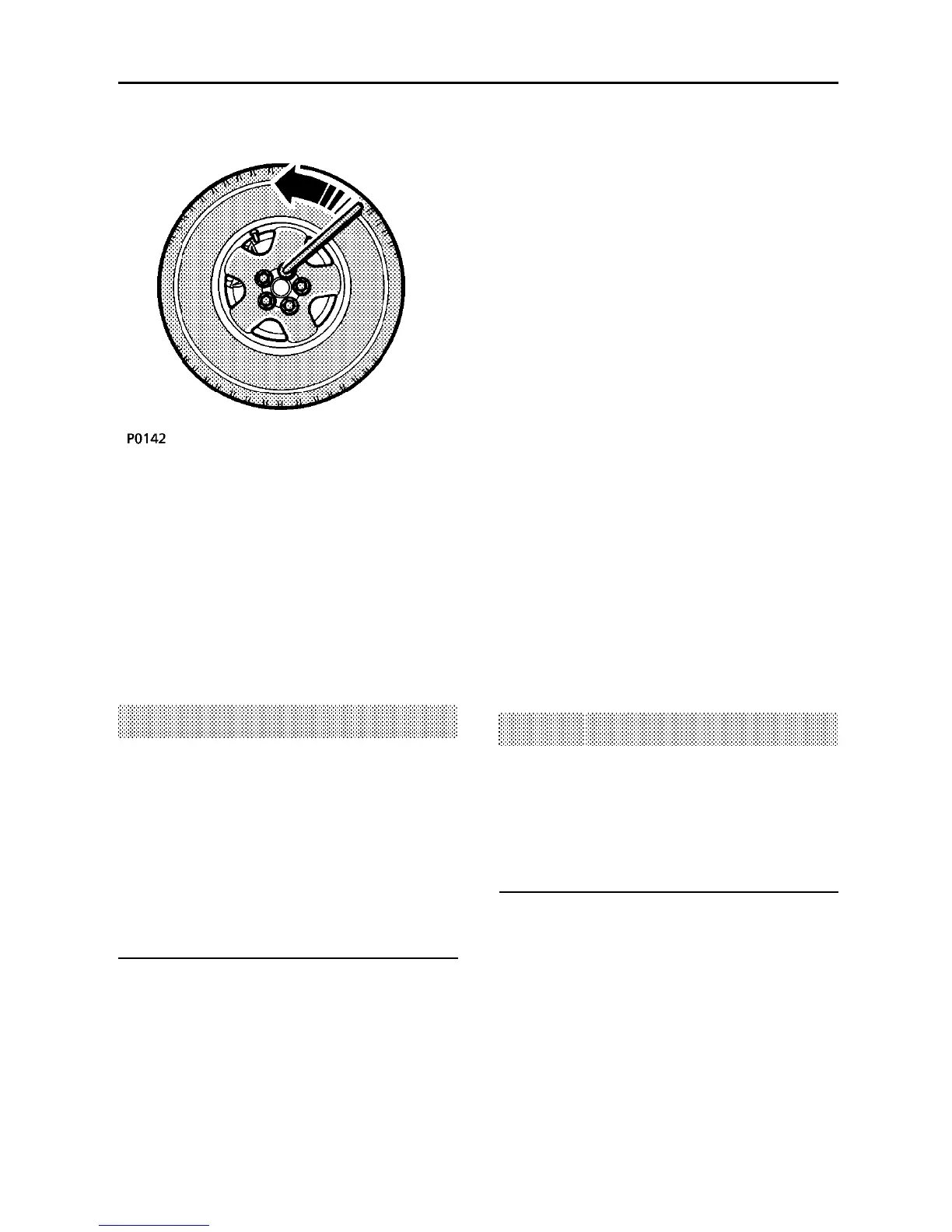

• Use the wheel brace to slacken the wheel

nuts half a turn anti-clockwise.

• Raise the vehicle until the tyre is clear of

the ground and remove the wheel nuts

and wheel (DO NOT damage the surface of

alloy wheels by placing them face down on

the road).

• Use an approved anti-seize compound to

treat the wheel-mounting spigot to

minimise the tendency for adhesion

between the wheel and the spigot. Ensure

that no oil or compound comes into

contact with the brake components. If, due

to an emergency situation, this treatment

is not practicable; refit the spare wheel for

the time being, but remove and treat the

wheel at the earliest opportunity.

• Fit the spare wheel and tighten the wheel

nuts, ensuring they are firmly seated. DO

NOT fully tighten whilst the tyre is clear of

the ground.

WARNING

When fitting a wheel, ensure that the mating

faces of the hub and wheel are clean and

free from rust - an accumulation of dirt or

rust could cause the wheel nuts to become

loose and result in an accident.

Loading...

Loading...