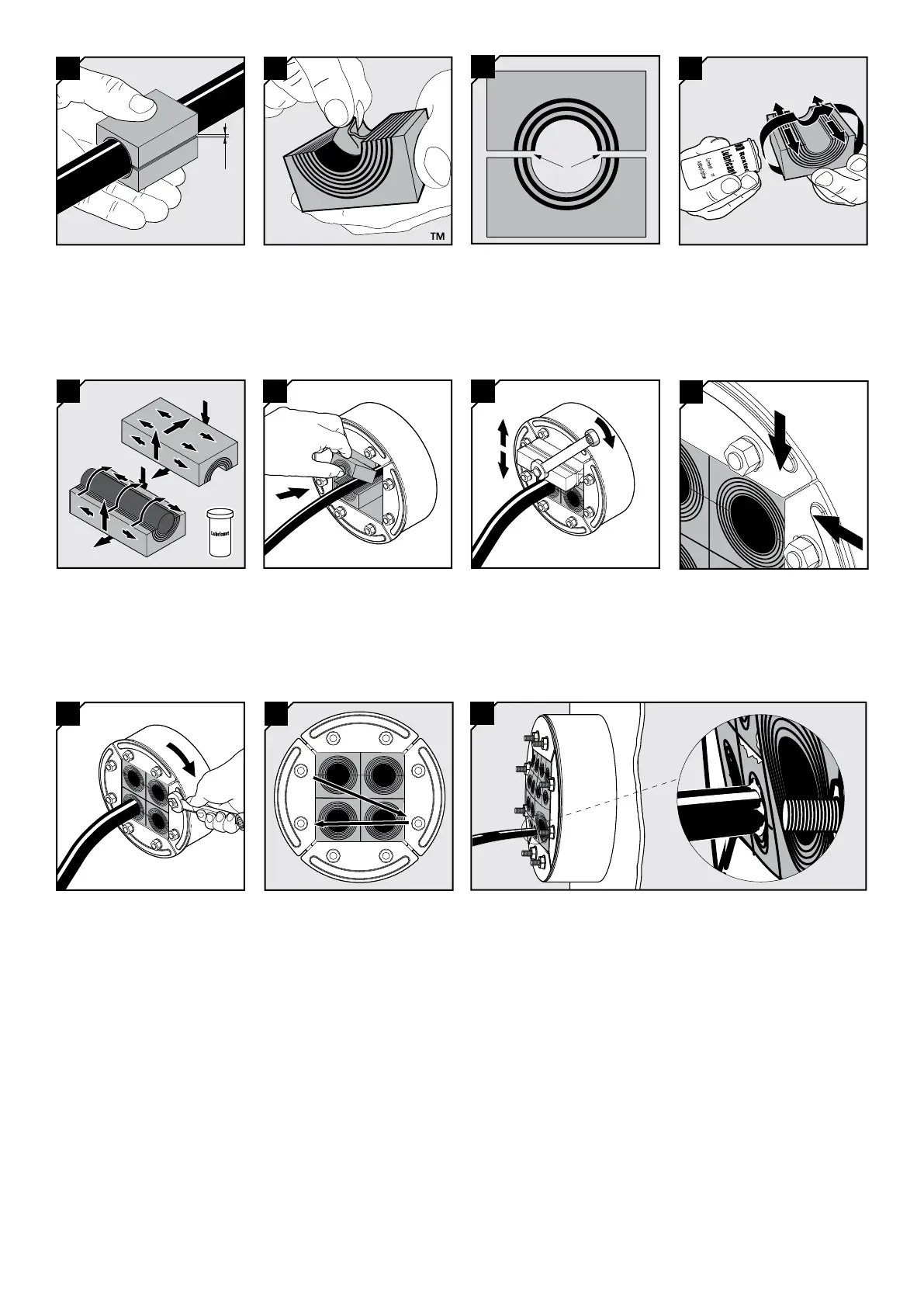

10

Adapt the modules by peeling

off layers.

11

The number of layers may not

differ (A) by more than one

between the corresponding

module halves.

12

Lubricate all sealing surfaces on

the modules.

9

Achieve a 0.1-1.0 mm (A) gap

between the two halves when

held against the cable/pipe.

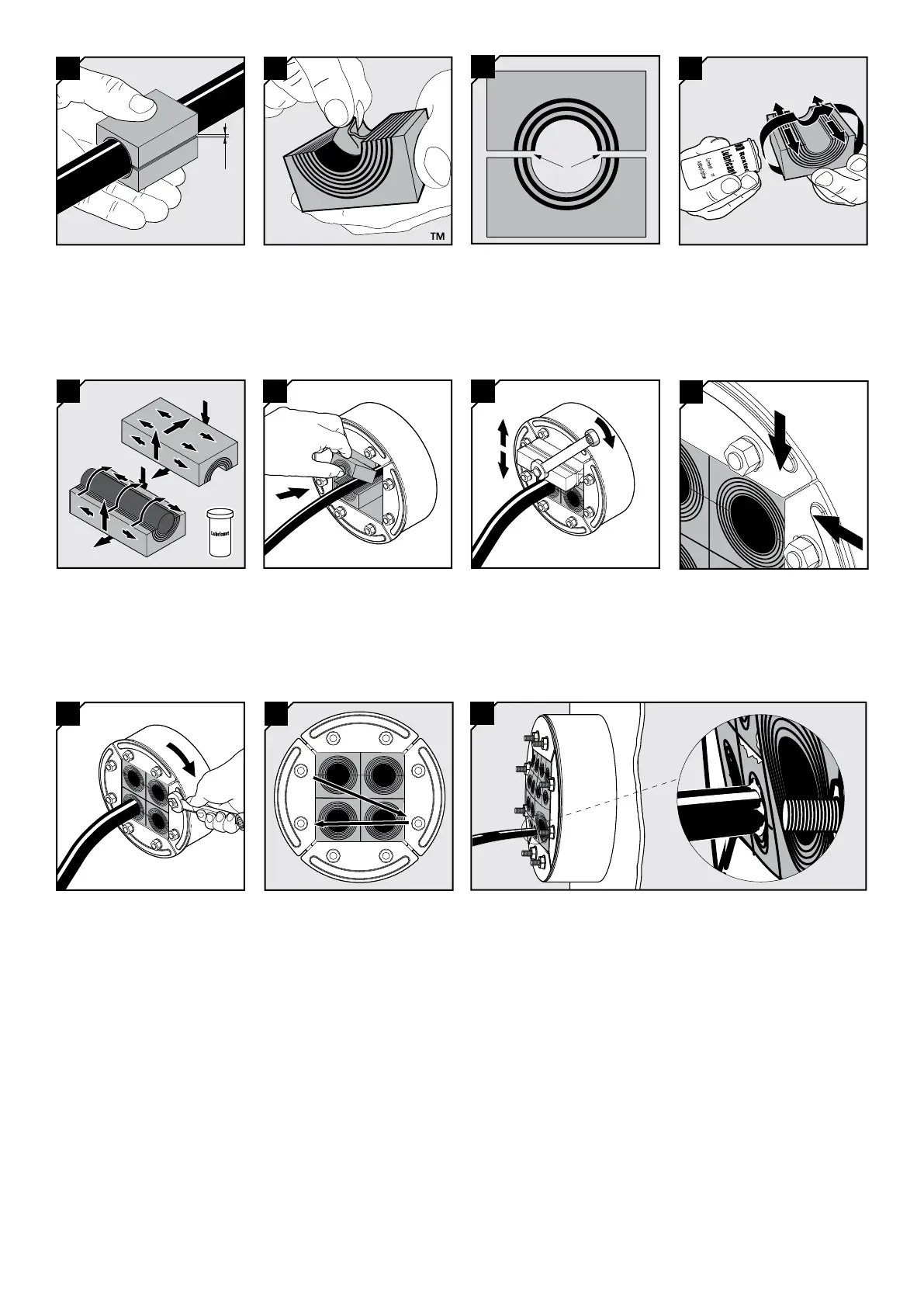

14

Insert the modules and cables/

pipes according to your packing

plan.

13

Lubricate the sealing surfaces

of the spare modules. Do not

remove the core.

17

Tighten the nuts crosswise in

small steps.

16

Push the front fittings back

towards the center.

15

A Roxtec pre-compression tool

can be used to make room

for the final module row, if

necessary.

Signs of good compression are: The bolts are tightened similarly.

Excessive lubricant is visible directly after installation. The rubber

surfaces bulge and show convexity.

19

18

Example of a crosswise

tightening pattern.

Note

O For optimum reliability, wait 24 hours or longer after installation before exposing the cables/pipes to strain or pressure.

O To be used with: RM modules.

O Cables/pipes shall be parallel to the sleeve/aperture.

O Cable/pipe with a considerable weight needs to be supported to prevent damage or subsidence to the seal.

O Approvals or certificates may include amendments or limitations related to this application.

O The latest version of this and related documents are found at roxtec.com.

Loading...

Loading...