Plumbing:

Thisbilgepumphasbeendesignedtobeusedwithexiblehose.Rigidpipingortubing

maydamagethepumporthepump’sdischarge.

Factorsthatreducetheowofabilgepumpmayincludebutarenotlimitedtothe

following:

• Thelengthofdischargepiping(longerrunsreduceow)

• The number or radius of bends

• Theroughnessoftheinteriorsurfacesofpipingandttings(smoothborehoseisbest)

• The reduction (hose restriction) in cross-sectional area of discharge system

components such as check valves and thru-hulls

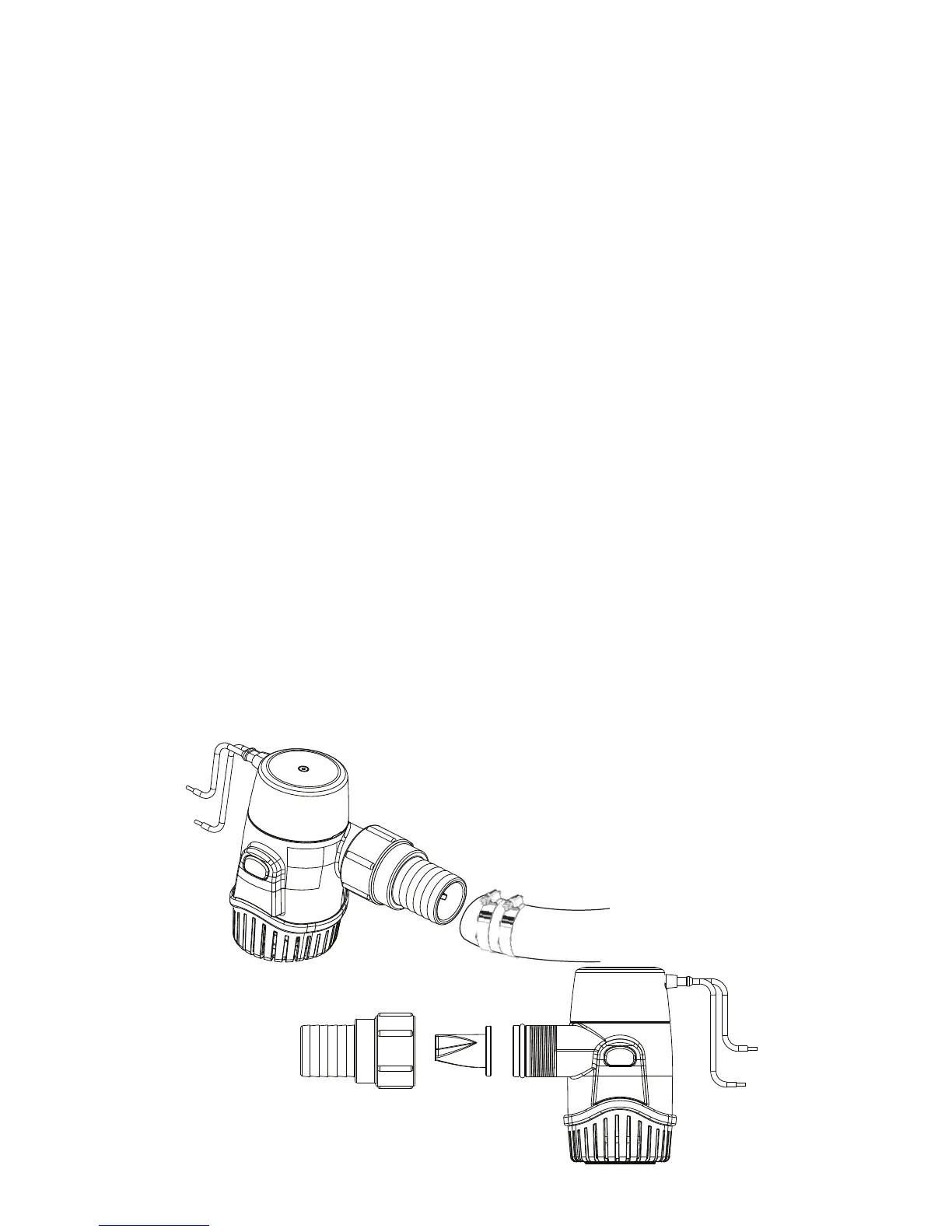

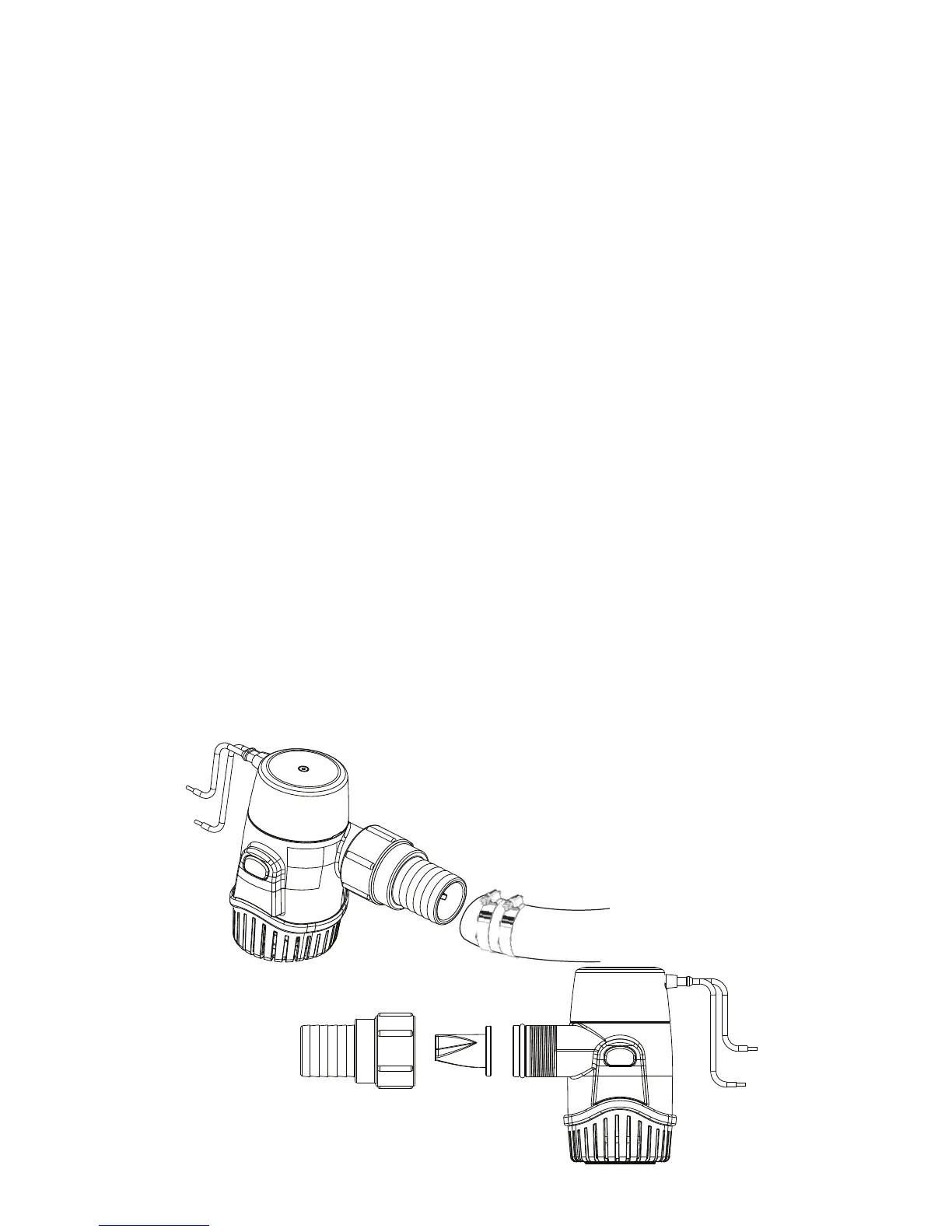

Attach the discharge hose to the hose barb using stainless steel hose clamps.

Thethru-hulldischargettingshouldbemountedatleast8”(20.3cm)abovethe

heeled water line to prevent water siphoning in from outside the vessel or the

discharge may be located below the maximum heeled waterline if the discharge

line is provided with both of the following:

• A seacock installed in accordance with the requirements of ABYC H-27, Seacocks,

Thru-Hull Connections, and Drain Plugs, and

• A vented loop or other means to prevent siphoning into the boat. A check valve

shall not be used for this purpose.

If the discharges of several pumps are manifolded to discharge through a single

thru-hulltting,thesystemshallbedesignedsothattheoperationofonepump

will not back feed another pump, and the simultaneous operation of each pump will

not diminish the pumping capacity of the system. A check valve shall not be used in

the discharge manifold system.

Best practice: Use two stainless steel hose

clamps to attach hose to hose barb.

A check valve may be used only when necessary to prevent an automatic bilge pump

fromcyclingonandoffduetobackowfromthedischargeline.

Hose connections shall be secured with a non-corrosive type of clamp, or be

mechanically fastened with permanently-attached end ttings, such as swaged

sleeve. Threaded inserts shall be attached with corrosion resistant metallic clamps.

6

During the winterization of a vessel, it’s

recommended that you remove the check

valve (if equipped) and drain any residual

water from the plumbing.

Periodically remove, clean and inspect bilge pump,

check valve and its surroundings for damage or

debris that may reduce the performance of the pump.

Loading...

Loading...