11 — English

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts could create a hazard or cause

product damage.

TROUBLESHOOTING

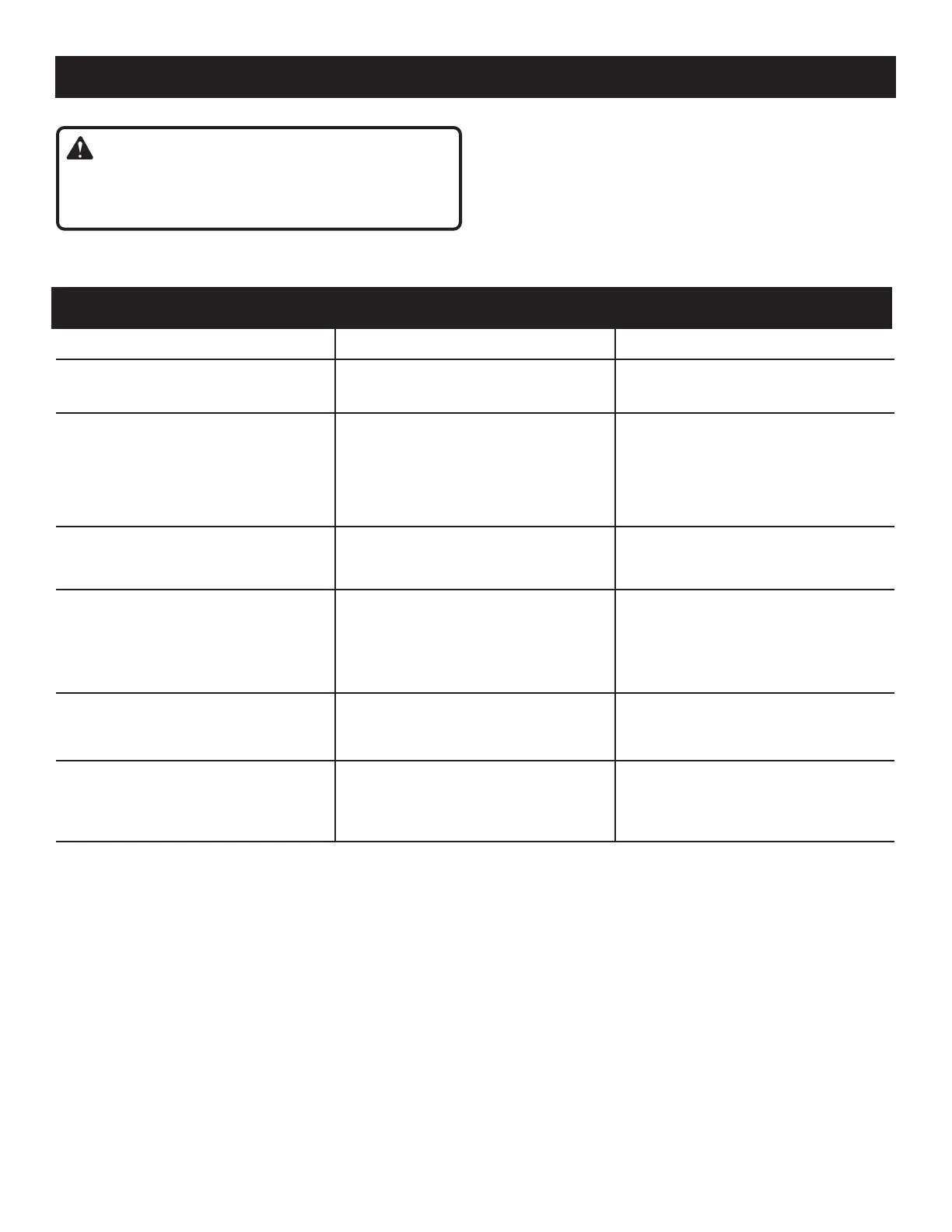

PROBLEM POSSIBLE CAUSE SOLUTION

Work-contacting element does not

depress fully - tool does not operate.

Low staples

Work-contacting element is jammed

Replenish staples

Remove battery and clear debris

Tool operates properly, but fasteners do

not drive fully

Air pressure is too low

Depth of drive isn’t deep enough

Staple is too long for wood hardness

Trigger released too soon.

Increase air pressure

Adjust depth of drive

Use staple length that is appropriate

for wood

Hold trigger until fastener is driven.

Tool operates properly, but fasteners are

driven too deep

Air pressure is too high

Depth of drive is too deep

Decrease air pressure

Adjust depth of drive

Tool jams frequently Incorrect staples

Damaged staples

Loose magazine

Dirty magazine

Verify that staples are the correct size

Replace staples

Tighten screws

Clean magazine

Tool stops and LED flashes rapidly. Battery is low or has no charge

Tool is hot

Recharge battery

Allow tool to cool

The tool has charged battery and LED

is slowly flashing or LED does not turn

off after approximately ten seconds of

non-use.

Tool has malfunctioned Take tool to nearest authorized repair

center

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

NOTE: ILLUSTRATIONS START ON PAGE 12

AFTER FRENCH AND SPANISH LANGUAGE SECTIONS.

Loading...

Loading...