Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

008831 en 2022.02

103/175

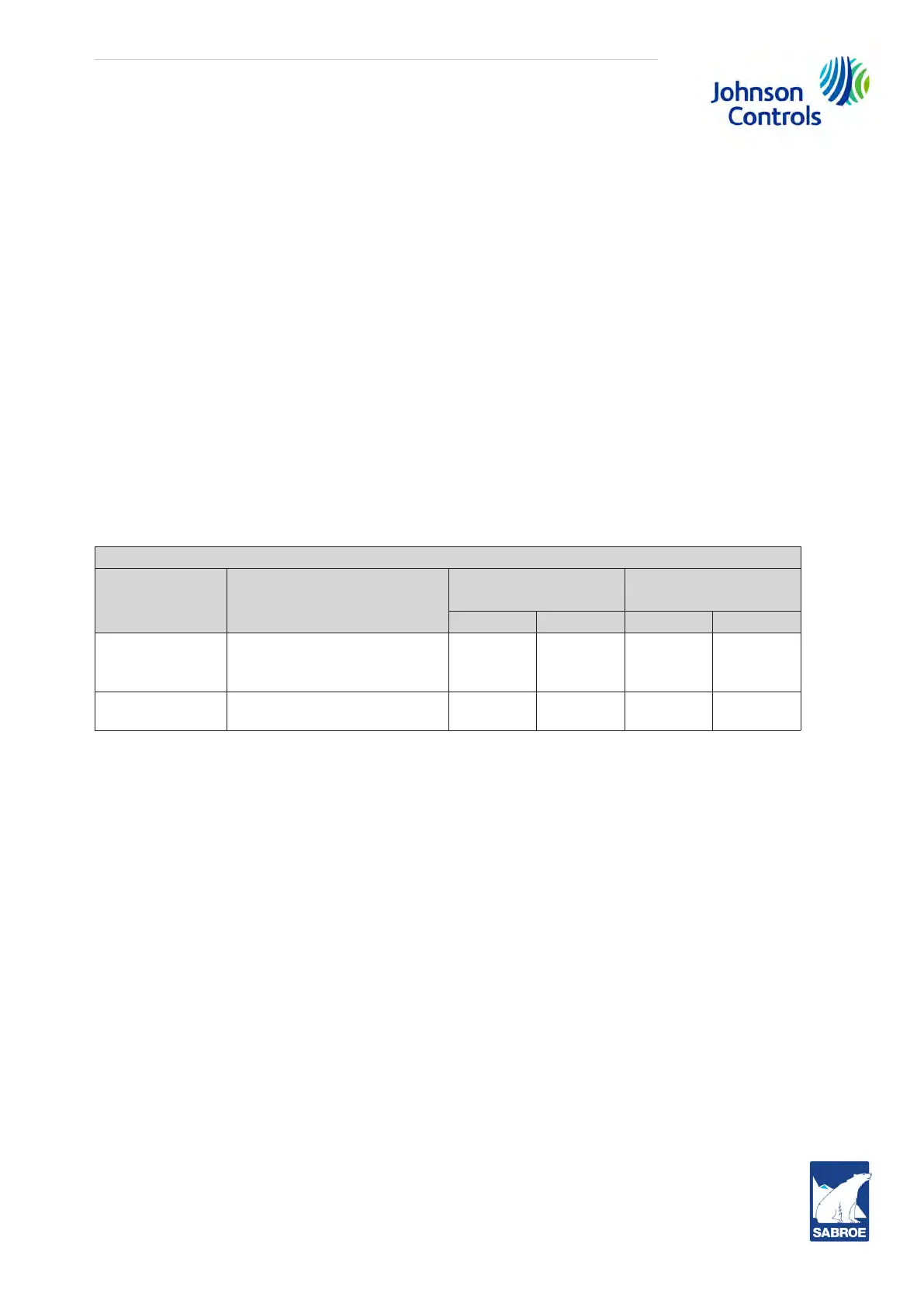

Technical data

6.15.2 Test pressure levels for standard compressors and components

All components for refrigeration plants which are under the influence of gas pressure must be

pressure tested to prove their strength and tightness.

The approving authorities determine the test pressure levels on the basis of various criteria.

However, the test pressure requirements can be summarised into a number of standard pres-

sure levels which in practice meet the requirements set up, and which can therefore be ap-

proved by all authorities involved.

Table 25 shows the standard pressure levels used by Johnson Controls Denmark. For specific

applications the authorities may, however, demand a higher test pressure level. Such require-

ments can be met, within certain limits, for Sabroe compressors at an additional price. Please

contact your local sales representative for further information.

When pressure testing compressors and vessels, components must first prove their strength

by resisting the test pressure of the strength test. This test is carried out with air.

Afterwards, the leak test is carried out, also with air, at the prescribed pressure for 30 minutes.

Units consist of components which have been pressure tested as described in the following ta-

ble. This means that it is only necessary to leak test the unit. Dwelling time is 20 minutes. Leak

testing is carried out with pressurised air at the pressure stated in the table. All weldings and

connections are covered with a frothing liquid which will start foaming in case of a leak.

Standard test pressure levels

Compressor

type

Compressor side

Strength

Testing

Leak testing with

pressurised air

bar [psi] bar [psi]

SAB 193

SAB 233

SAB 283

The entire compressor block

40.3

[566]

28

[377]

Compressor

unit

All types

The entire unit

40.3

[566]

28

[377]

Table 25: Test pressure levels

Loading...

Loading...