Quick Reference Guide

Tissue-Tek® Glas™ g2

QRG | Glas g2 | 2010 | V-5 page 5 | 11

Coverslipping Operation

Cover slipping slides

Pre-operational checks

1. Turn on POWER.

2. Remove the loading station lid.

3. Check the solvent volume level in anti-drying

bottle and dispensing pump reservoir.

4. Clean any possibly spilled mounting medium.

5. Place receiving racks in the unloading area.

6. Confirm there is no basket in the carousel.

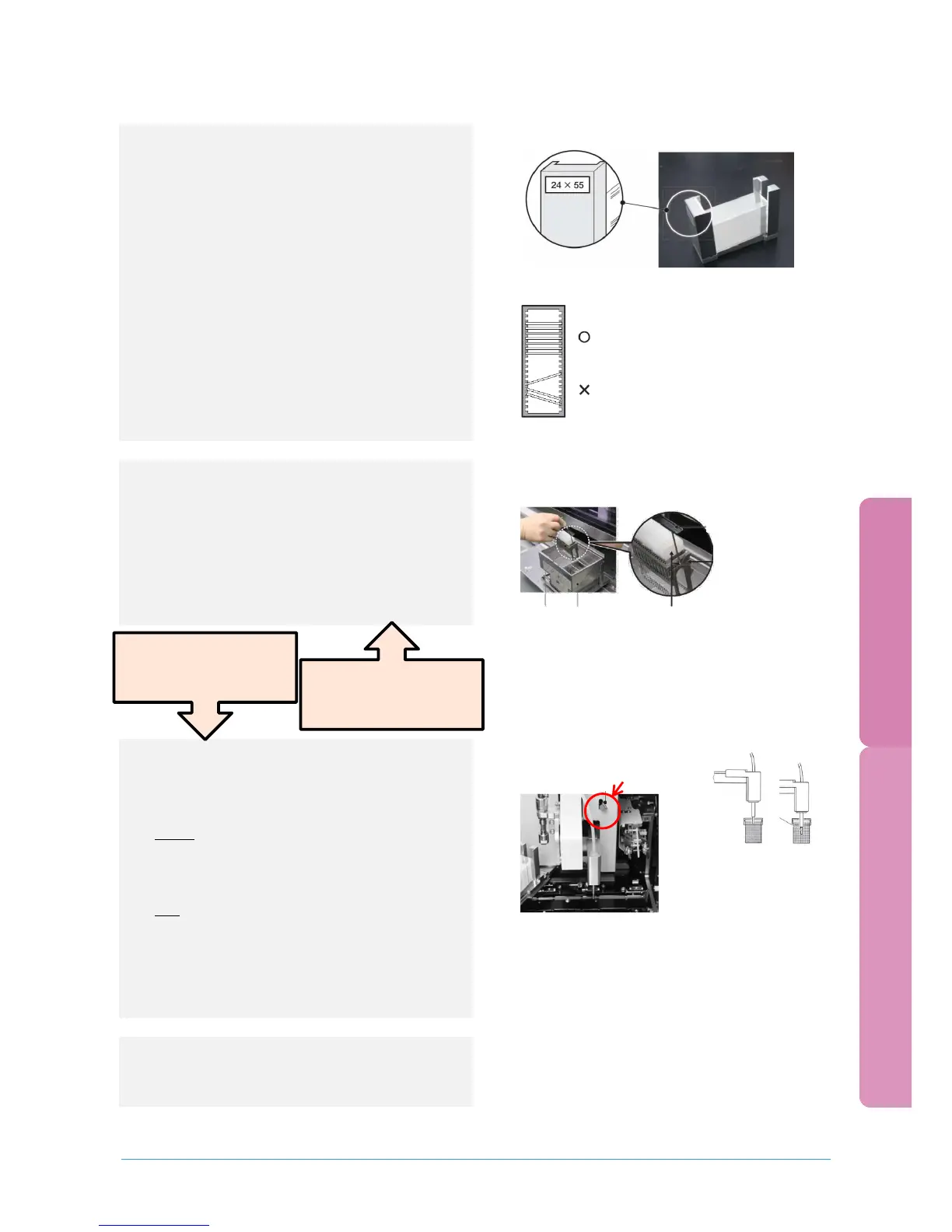

7. Put coverglass holders in place and fill with

coverglasses, or refill the coverglass holder

with the correct coverglasses.

8. Check if CG size on screen matches CG in

holder.

9. Check the volume level of mounting medium.

Start of operation

1. Check coverglass size, coverslipping speed and

volume of mounting medium.

2. Select coverslipping program.

3. Press and hold [prime] key for 3 seconds.

4. Pull out the loading station and set baskets.

Close loading station door and [start]

coverslipping.

End of Operation

1. Remove empty receiving racks.

2. Remove empty baskets.

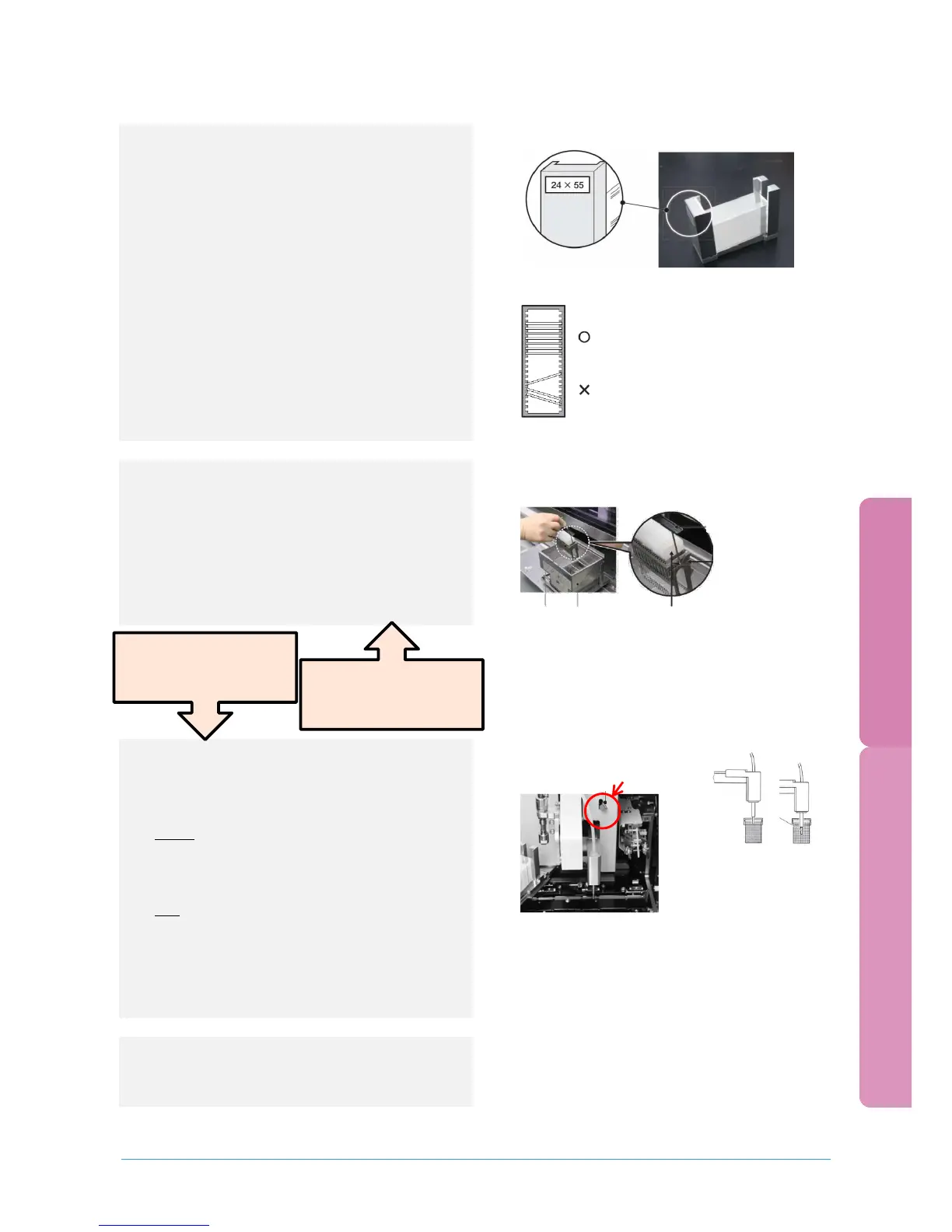

3. Place dispensing nozzle in the anti-drying bottle

above the xylene, to keep the nozzle in a

xylene vapor (normal state). Only if the

instrument is not used for an extended period

of time (one week or more) the nozzle is placed

into the xylene by tilting the lever at the rear of

the nozzle. If coverslipping is resumed after the

nozzle has been soaked in xylene, press the

PRIME key to discharge mounting medium

that has been mixed with xylene from the

nozzle.

Power off

1. Turn off power and place the lid on the loading

station.

Insert slides in parallel

Set by making sure

the “UP SIDE” marks are

If coverslipping is to be

continued, return to the

standby screen and add

Loading...

Loading...