Installation and operating instructions Salmson SXS / NSB-S 35

English

• Install appropriate flat gaskets between pump and counter flanges.

• Tighten the flange bolts across diagonals in two steps to the prescribed tight-

ening torque (see Table 7.1.2).

• Step 1: 0.5 x permissible tightening torque

• Step 2: 1.0 x permissible tightening torque

• Check the flange connections for leaks.

7.2 Electrical connection

DANGER! Danger of death!

Improper electrical connections pose a risk of fatal injury due to electric shock.

• Only allow the electrical connection and all associated activities to be made

by an electrician approved by the local electricity supplier and in accordance

with the local regulations in force.

• Before working on the pump, all poles of the power supply must be discon-

nected. Because voltages hazardous to persons persist for some time

(in capacitors), no work may be commenced on the module until 5 minutes

have elapsed (applies only to 1~ systems). Check to ensure all connections

(including potential-free contacts) are voltage-free.

• If the module/terminal box is damaged, do not operate the pump.

• If the setting and operating elements on the module/terminal box are unduly

removed, there is a danger of electric shock by touching the electrical com-

ponents located inside.

CAUTION! Risk of damage!

An incorrect electrical connection can cause damage to property.

If the wrong voltage is applied, the motor can be damaged!

• The current type and voltage of the mains connection must correspond to the

specifications on the name plate.

• The electrical connection must be established via a fixed connection line

equipped with a connector device or an all-pole switch with a contact opening

width of at least 3 mm.

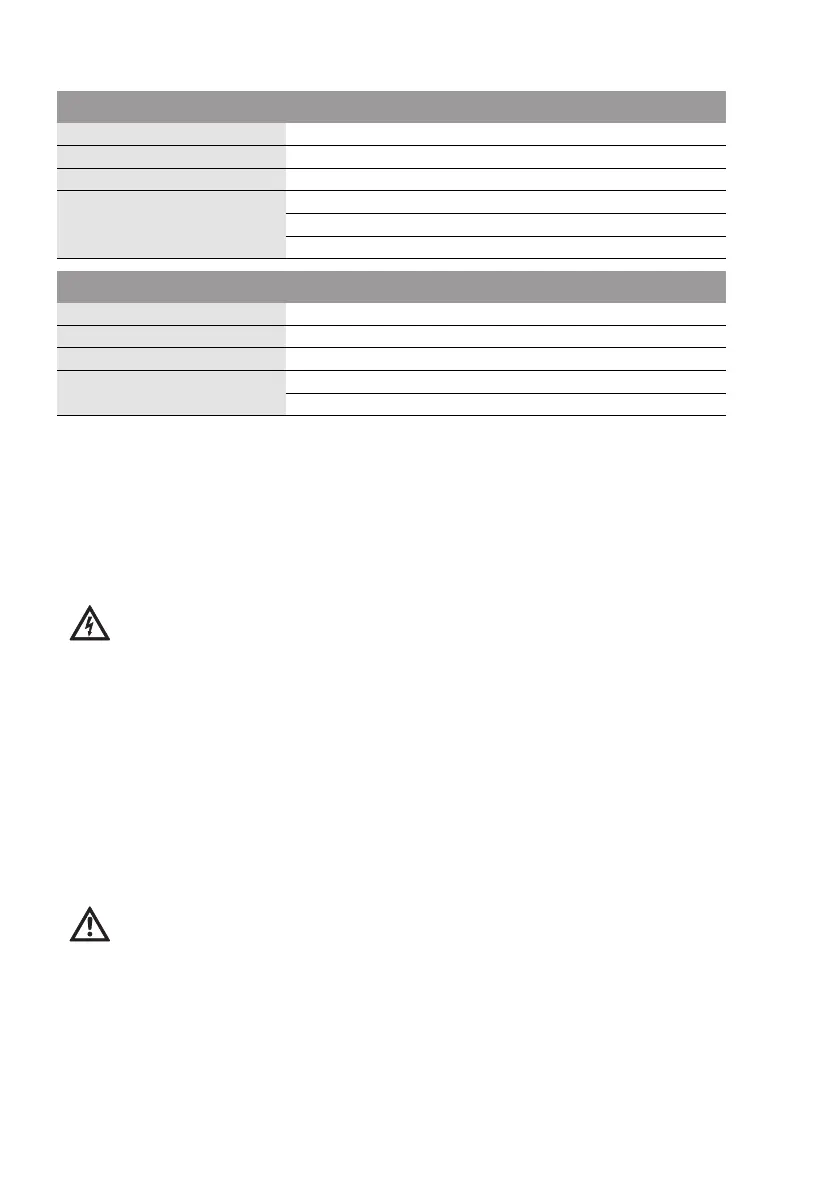

DN 40, 50, 65 Rated pressure PN 6 Rated pressure PN 10/16

Screw diameter M12 M16

Tensile strength class ≥ 4.6 ≥ 4.6

Permitted tightening torque 40 Nm 95 Nm

Min. screw length for

• DN 40 55 mm 60 mm

• DN 50/DN 65 60 mm 65 mm

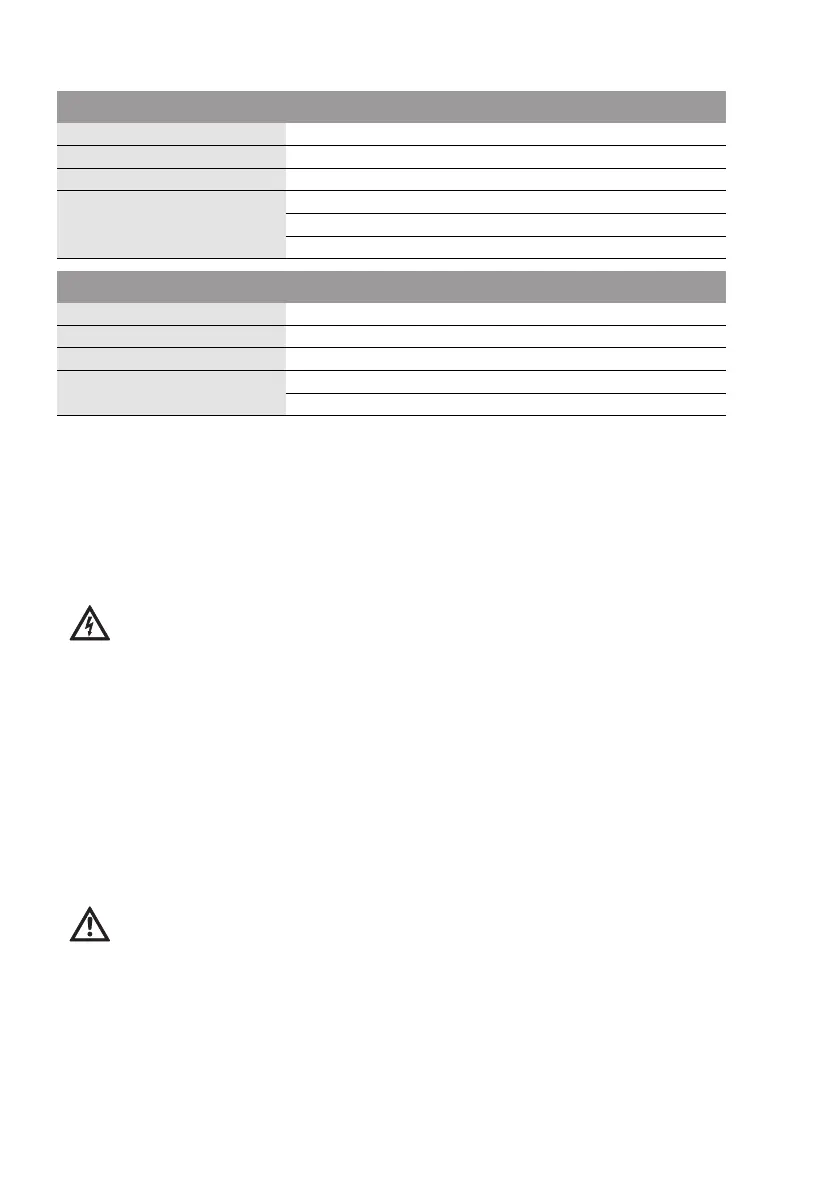

DN 80 Rated pressure PN 6 Rated pressure PN 10/16

Screw diameter M16 M16

Tensile strength class ≥ 4.6 ≥ 4.6

Permitted tightening torque 95 Nm 95 Nm

Min. screw length for

• DN 80

65 mm 65 mm

Loading...

Loading...