SP | Sheave Mountaing and Alignment | Tensioning

7

CHECK SHEAVE MOUNTING AND

ALIGNMENT

V-Belt drives do not require alignment to as close

tolerances as most other types of drives - but

unless the belts enter and leave the sheaves in a

relatively straight line, wear is accelerated.

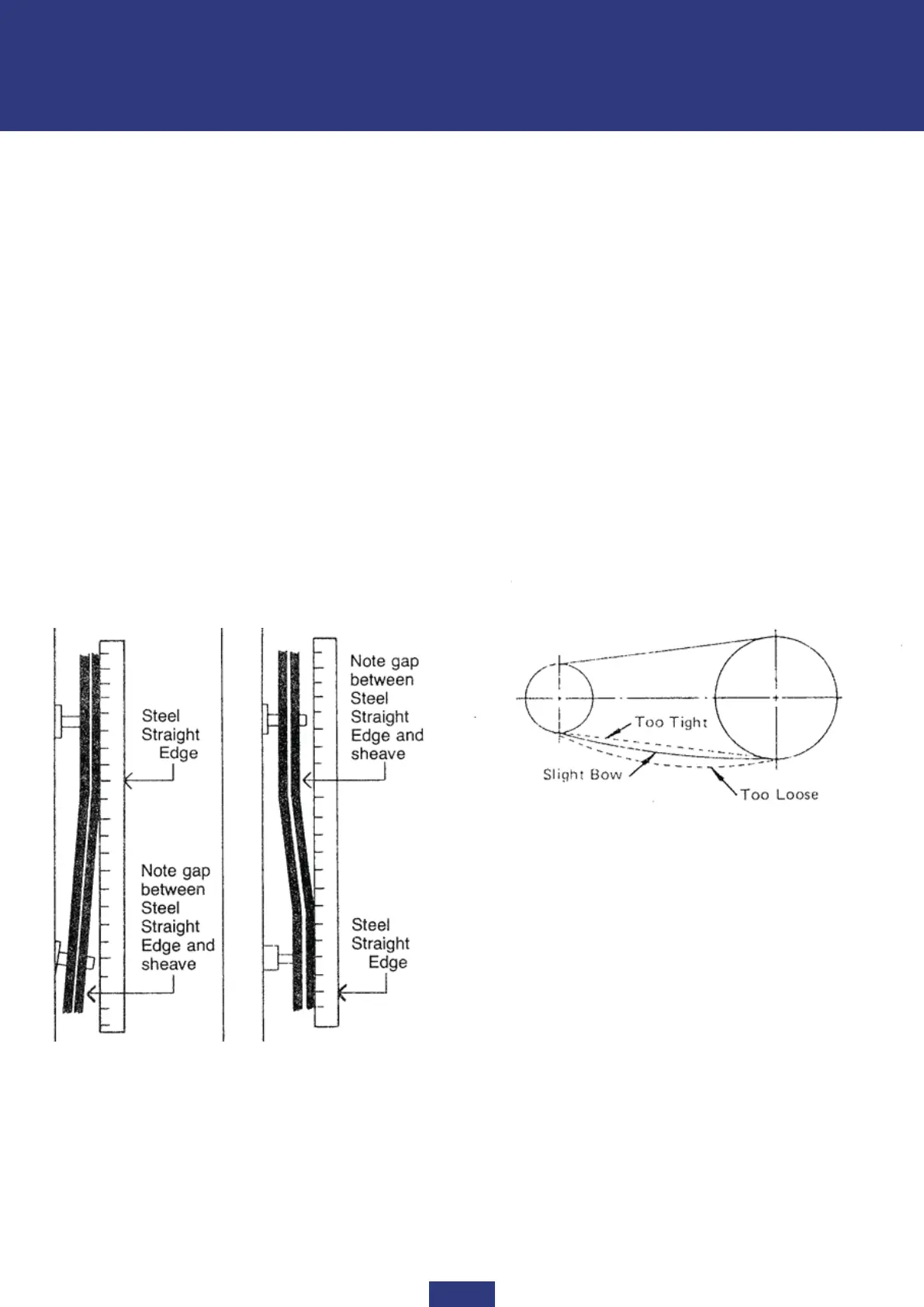

The two most common causes of misalignment are

shown: (a) the shafts of the driver and driven

machines are not parallel, and (b) the sheaves are

not located properly on the shafts. To check align-

ment, all you need is a straight edge or, for drives

with longer centres, a steel tape. If these aren't

available, you can, as a last resort, even use heavy

string. Just line the straight edge or tape along the

outside face of both sheaves as shown in the

illustration. Misalignment will show up as a gap in

between the sheave face and straight edge, or

perhaps as a "break" in the tape or string. Make

sure that the width of the outside land is equal on

both sheaves, when using this method.

V-BELT DRIVE TENSIONING METHOD

Before attempting to tension any drive it is

important that the sheaves be properly installed

and aligned. The V-belts should be placed over the

sheaves and in the grooves without forcing them

over the sides of the grooves.

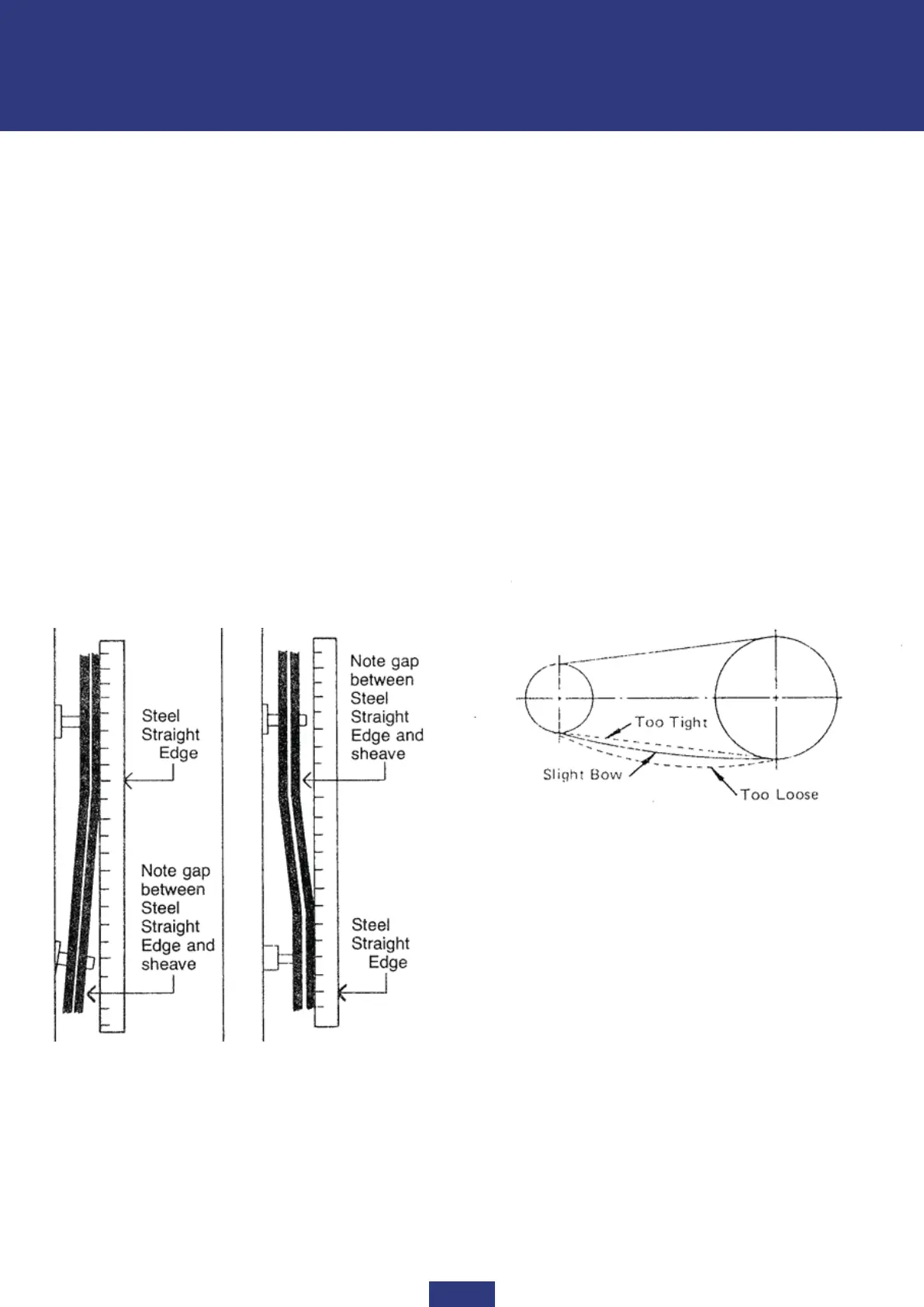

Step 1: With all belts in their proper groove, adjust

the centres to take up all slack and until the belts

are fairly tight.

Step 2: Start the drive and continue to adjust until

the belts have only a slight bow on the slack side

of the drive while operating under load. See

sketch.

Step 3: After a few days of operation, the belts will

seat themselves in the sheave grooves and it may

become necessary to readjust so that the drive

again shows a slight "bow" in the slack side.

The drive is now properly tensioned and should

operate satisfactorily with only an occasional

readjustment to compensate for belt and groove

wear.

Loading...

Loading...