TR90-Series Due to continuing product development, specications are subject to change without notice. © 2018 S&P

132104_002 Revised 8/2018 Page 3

Exhaust & Outside Air Ducts

The Exhaust Air Duct and the Outside Air Duct connect the unit to

the outside. Flexible insulated duct is typically used. See Table

under “Duct Sizes” below.

DO NOT PLACE ANY STALE AIR RETURNS IN GARAGES.

Can an ERV be used to ventilate bathrooms?

A S&P ERV can be used as a central exhaust system in place of

bathroom exhaust fans. Tie a grill in each bathroom directly

back to the ERV – see Schematic (A). A successful installation

should provide at least 50 CFM of exhaust per moisture producing

bathroom. When used for bathroom exhaust, the TR90 should

be used for only one bathroom. Install a control in the bathroom

ventilated by the ERV (see Secondary Operating Controls, below).

For houses where radon is a concern:

The rst line of defense against radon should always be techniques

that prevent the entry of radon into the home, such as under-slab

suction, vented perimeter drainage, and crack sealing. However,

if moderate levels of radon continue to be present, it is important

that the unit slightly pressurize the basement, not de-pressurize

the basement.

Installation of this unit for radon mitigation is beyond the

scope of this manual. Consult a radon mitigation professional.

Duct Minimum Sizes and Type

Exhaust Air & Outside Air

(EA & OA)

6” round insulated duct

8” round insulated duct may be

used to maintain maximum airow

Fresh Air & Stale Air

(FA & RA)

6” round or 8” oval rigid

un-insulated

All ducts from unit to house in unconditioned spaces like

attics and crawl spaces MUST BE INSULATED.

Duct Sizes

Controls

For an installation in which the ERV should run continuously in

order to provide the required ventilation rate for the home,

no controls are needed. However, in most installations, control

over the unit operation is desired and this is best provided by a

Proportional Timer.

Proportional timers (SPTL or SFM controls for TR90 or line voltage

controls for TR90G) may be located anywhere that is convenient.

A typical location for either control is next to the home’s

thermostat. Proportional timers operate the ERV to provide

regular background ventilation of the home.

TR90 installations that pull stale air from specic rooms, such as

bathrooms, should have Push-Button Lighted (SPBL) Controls in

those rooms. The secondary operating controls allow the system

to be turned on from various locations in the house.

Mounting the Unit

Unit may be installed in any orientation:

Orient the unit for the simplest duct layout and connections.

Note however that the door is equipped with slide-o hinges. For

the homeowner’s convenience it is helpful to orient the unit so

that the door does not drop o when it is unlatched.

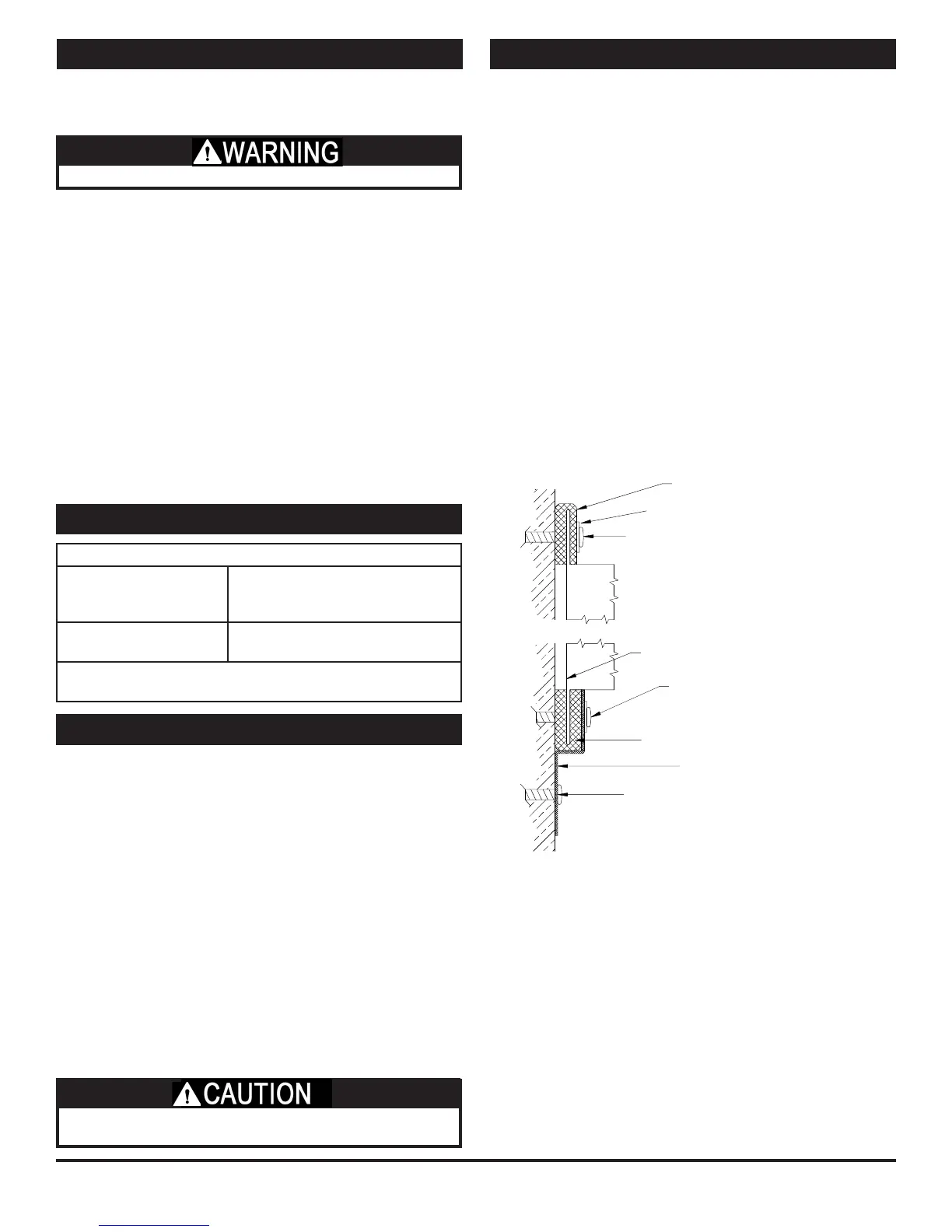

Mounting the TR90 on a concrete foundation wall:

Mount hanging bracket to the wall with appropriate concrete

anchors. Use pre-cut foam tape from small parts bag. Remove

backing and apply two pieces of foam tape equally spaced along

the unit’s mounting ange to be held by the hanging bracket. Apply

the other two pieces of foam over two holes that will be used for

fastening, on the other ange. The tape should be applied in a “U”

shape to cushion both the front and back of the integral anges.

Lift unit and slide unit ange into the hanging bracket. Using metal

at washers, fasten ange opposite hanging bracket to structure.

Safety screws should similarly be installed passing through the

hanging bracket and ange. Make sure the screws, which you must

supply, are properly selected for the loads and substrate involved.

Mounting the TR90 to a stud wall:

Mount unit using supplied hanging bracket kit as described for

mounting to concrete foundation wall. Note that the hole layout

on the integral mounting anges and the hanging bracket are

spaced for 16” on-center framing patterns.

Foam Tape

Foam Tape

Metal Washer

Lag Screw or Concrete Anchor

(provided by others)

Lag Screw or Concrete Anchor

(provided by others)

Unit Flange

Optional Washer and Screw

(provided by others)

Hanging Bracket

* TR90 only.

Suspending the TR90 from oor joists or trusses:

The unit may be screwed directly to joists or trusses using the

hanging bracket and integral ange. Mount as described for

mounting to concrete foundation wall. Note that the hole layout

on the hanging bracket is spaced for 16”on-center layouts.

Mounting the TR90G:

The TR90G can be mounted similar to the TR90 however, the

TR90G does not come with a hanging bracket. Using at washers

provided install screws through the holes in the anges of the

unit. Make sure the screws, which you must supply, are properly

selected for the loads and substrate involved.

RISK OF INJURY WHEN LIFTING UNIT AND INSTALLING UNIT

OVERHEAD. GET A HELPER AND WEAR EYE PROTECTION.

Loading...

Loading...