– 11 –

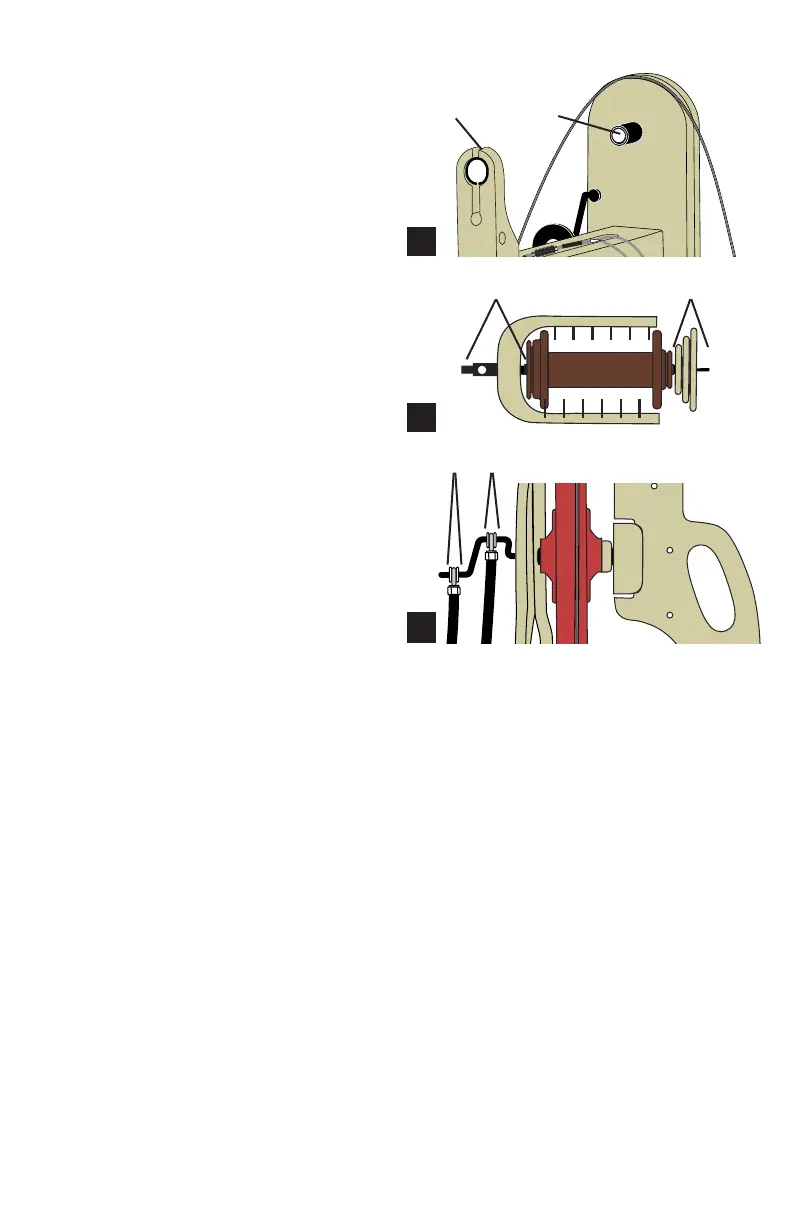

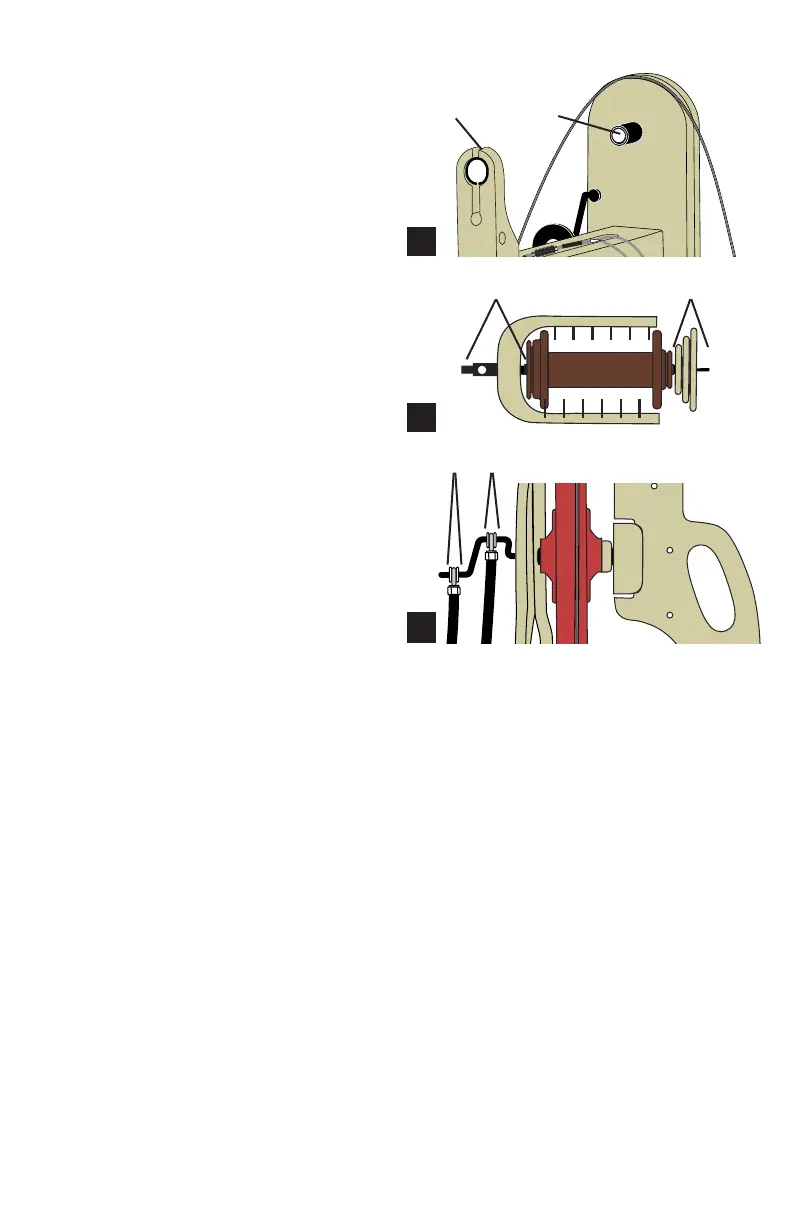

rear

bearing

front

bearing

A

footman contact points

C

FIGURE 12: OILING

B

oil here oil here

LUBRICATING MOVING PARTS

Your wheel was lubricated and tested at

the factory before it shipped, but it may

have sat unused for a while since then.

Before spinning, and for every few hours

of spinning, oil it with a medium-weight oil

such as 20- or 30-weight SAE motor oil.

Use a drop of oil

■ inside the front bearing & rear bearing

(Figure 12A)

■ on the yer shaft where it touches front

bearing, rear bearing, and bobbin ends

(Figure 12B)

Oil the footman contact points sparingly

(Figure 12C).

Never oil the spinning wheel hub or the

plastic drive wheel. If a squeak develops

elsewhere on the wheel, try a few drops of

oil in this area.

THE FINISH ON YOUR WHEEL

Your wheel has been nished with

Danish oil, which penetrates into the

wood. If you need to touch up chips or

scuffs, lightly sand the worn area and

apply a small amount of nish using a

soft, lint-free rag. Use Deft natural color

Danish oil, following the directions on the

container. Always clean and dispose of

applicators and oily rags according to the

manufacturer’s instructions.

If your wheel needs more thorough

cleaning (for example, dirty treadles),

wipe it down using mineral spirits and a

rag, then reapply Danish oil as described

above.

SERIAL NUMBER

Your wheel’s serial number is stamped

into the wood on the rear of the mother-

of-all. The rst six digits are the date of

assembly. The remaining digits are a

sequence number for wheels built that

day. •

Loading...

Loading...