The 8th DIP SWITCH key allows to make a rapid

check up of the P.C. BOARD output connections

(compressor, water pump, fan motor, water inlet

and hot gas solenoid valves) energizing them in

rapid sequence (2 seconds) one by one.

DURING THE AUTOMATIC OPERATION OF

THE ICE MAKER THIS KEY MUST BE SET IN

OFF POSITION.

ATTENTION. The check up of the

P.C.BOARD output must be performed in

a very short time in order to avoid frequent

start and stop (every few seconds) of the

electrical components which may damage

them specially the compressor.

The 9th key allows the operation of the water

pump even during the defrost cycle, as required

when it is necessary to drain out the remaining

water from the sump.

The 10th key is used to supply power to the water

pump for the first 15 seconds of the defrost cycle

(ACM 85, AC 125 & AC 175) - position OFF - and

for the first 30 seconds - position ON (AC 225).

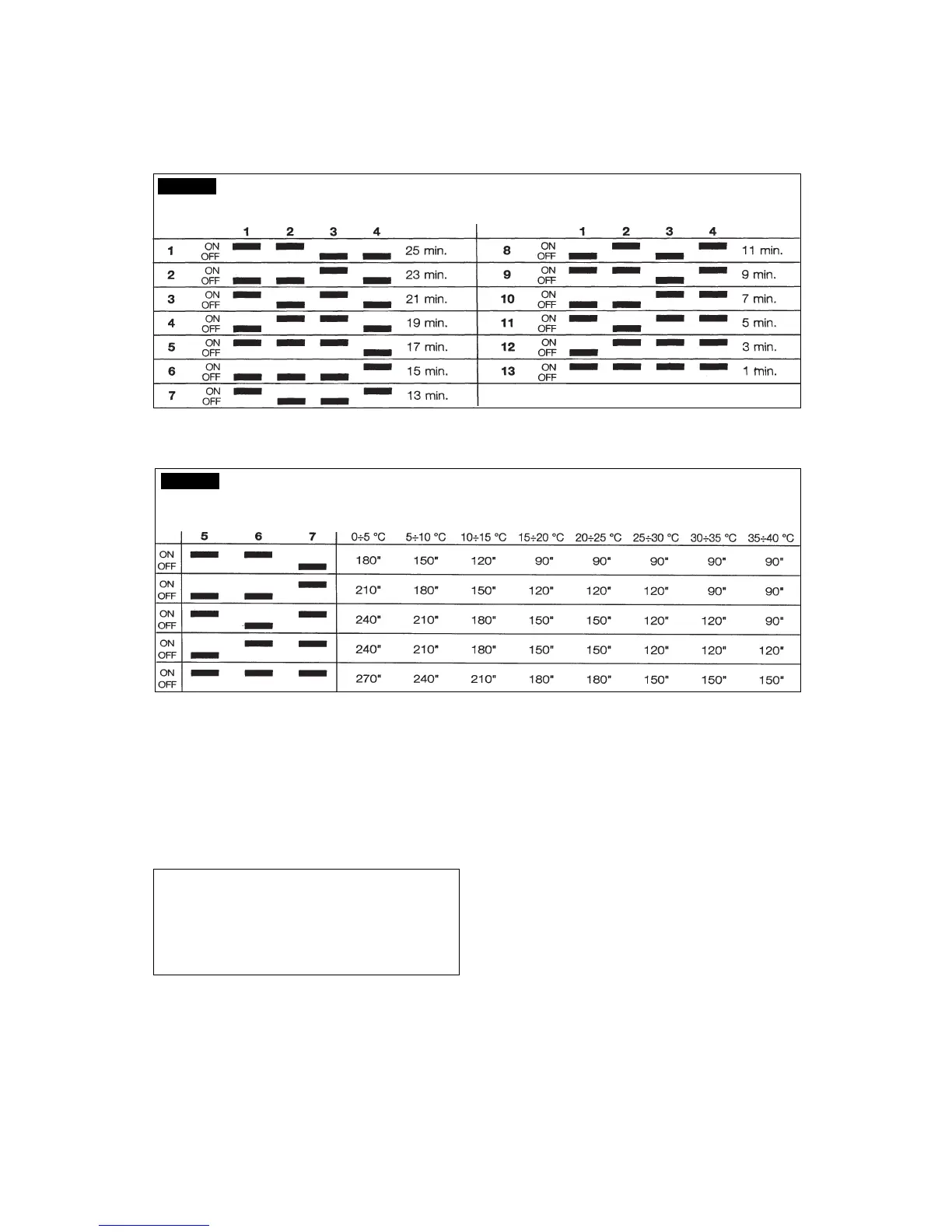

LENGTH OF TIMED PORTION OF FREEZING CYCLE ACCORDING TO THE

DIP SWITCH SETTING COMBINATIONS

The DIP SWITCH first four keys setting

determines the length of the 2nd phase of

freezing cycle (controlled by the electronic

timer) as detailed in the table B.

TAB. B

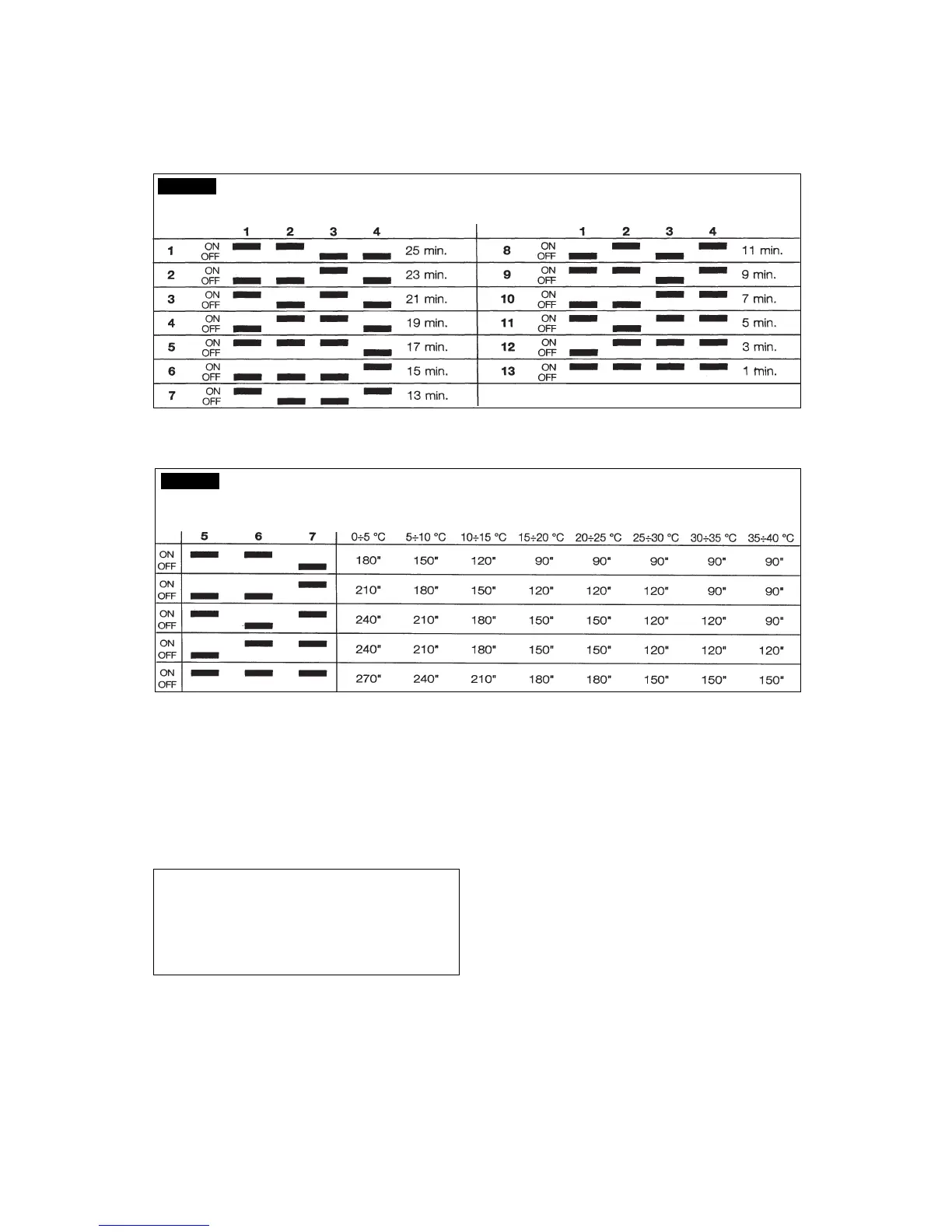

The DIP SWITCH keys 5, 6 and 7 setting

determines the length of the defrost cycle

according to the ambient temperature sensor as

specified in table C.

LENGTH OF DEFROST CYCLE (IN SEC.) ACCORDING TO THE

AMBIENT TEMPERATURE AND TO THE DIP SWITCH SETTING COMBINATIONS

TAB. C

G. WATER SPRAY SYSTEM

Through its nozzles, the water pumped, is sprayed

in each individual cup to be frozen into ice.

It consists of one spray platform on model

ACM 85 and two separated spray platforms on

AC 125-175 which have six spray nozzles each.

On the AC 225 the spray bar is self rotating being

propelled by a stream of water passing through

an hole located in one arm of the spray bar.

H. WATER PUMP

The water pump operates continually throughout

the freezing cycle and on the first 15 or 30

seconds of the defrost cycle so to such the

remaining water from the sump tank (reach in

mineral salts) and drain it out.

During the freezing cycle the pump primes the

water from the sump to the spray system and

through the spray nozzles sprays it into the

inverted cup molds to be frozen into crystal clear

ice cubes.

It is recommended that the pump motor bearings

be checked at least every six months.

Page 25

Loading...

Loading...