5. Remove the evaporator cover then slowly

pour onto the evaporator platen the cleaning

solution. With the help of a brush dissolve the

most resistant and remote scale deposits in the

platen.

6. Set the program selector head on

CLEANING/RINSING.

The 5th YELLOW LED lights-up (Fig.9).

NOTE. With the system in CLEANING/

RINSING mode the water pump is the only

component in operation to circulate the

cleaning solution in the entire water system.

7. Let the unit to remain in the CLEANING/

RINSING mode for about 20 minutes then turn

the program selector on STAND BY again.

8. Flush out the cleaning solution from the

sump reservoir then pour onto the evaporator

cavity two or three liters of clean potable water to

rinse the mold cups and the platen.

If necessary remove the water spray bar or spray

platen to clean them separately as per steps 3

and 4 of paragraph B.

9. Turn again the program selector on

CLEANING/RINSING. The water pump is again

in operation to circulate the water in order to rinse

the entire water system.

10. Flush out the rinsing water from the sump

reservoir then turn the program selector on

RE-SET/HI TEMPERATURE position and

immediately afterward to FREEZING

OPERATION.

NOTE. By setting the selector on RE-SET

first and then to FREEZING OPERATION

the ice maker will perform the 5 minutes

WATER FILLING phase i.e. the water inlet

solenoid valve opens to allow the incoming

water to rinse again the water system and to

properly fill-up the sump reservoir for the

next freezing cycle.

Sanitation

NOTE. Sanitation of the water system is

recommended to be done once a month.

11. Prepare in a plastic container the sanitation

solution as per manufacturer dilution using warm

water (45-50 °C).

NOTE. Never mix the cleaning with the

sanitising solution.

12. Follow the procedures as per cleaning (from

item 4 to item 10) just shorting the operation of

the water pump to 10 minutes.

Page 40

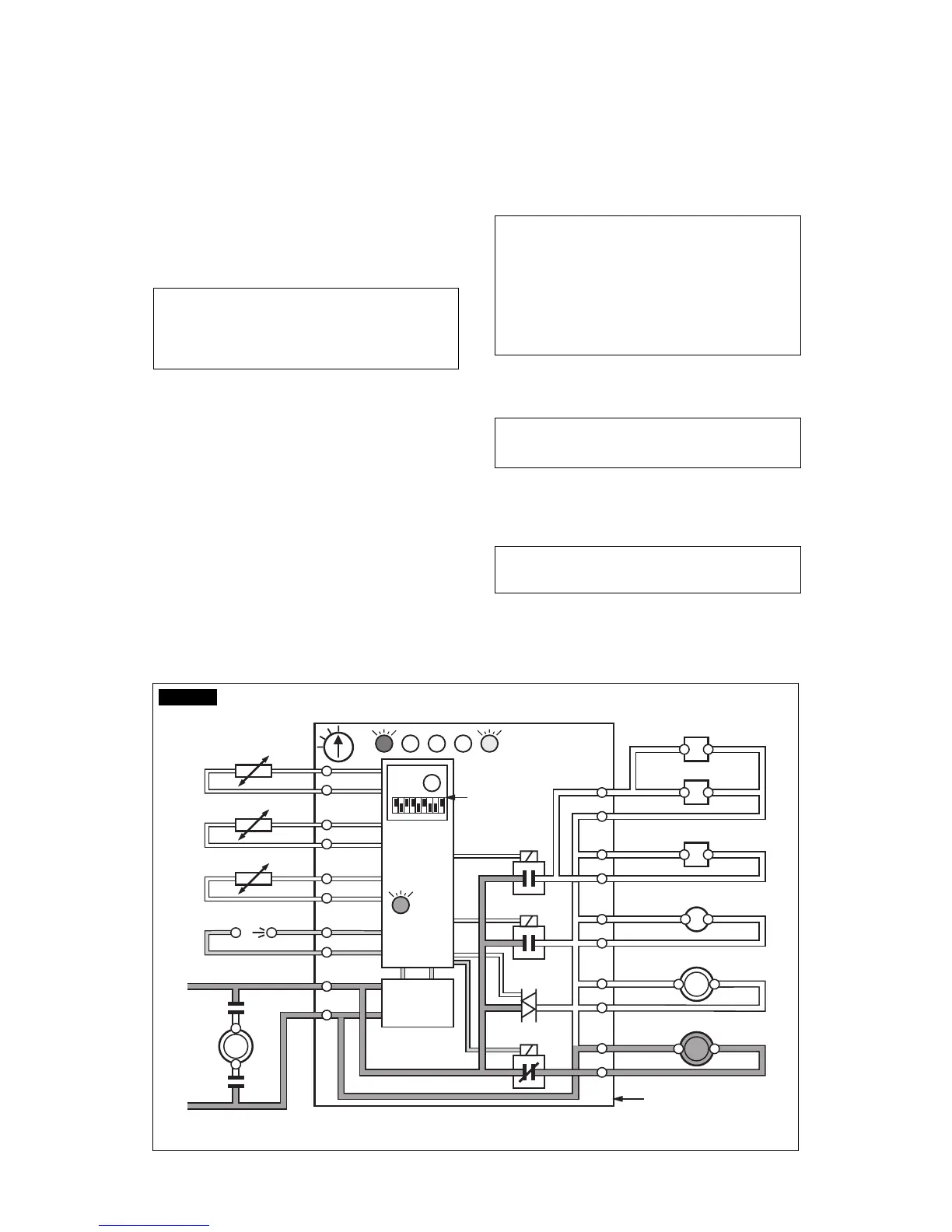

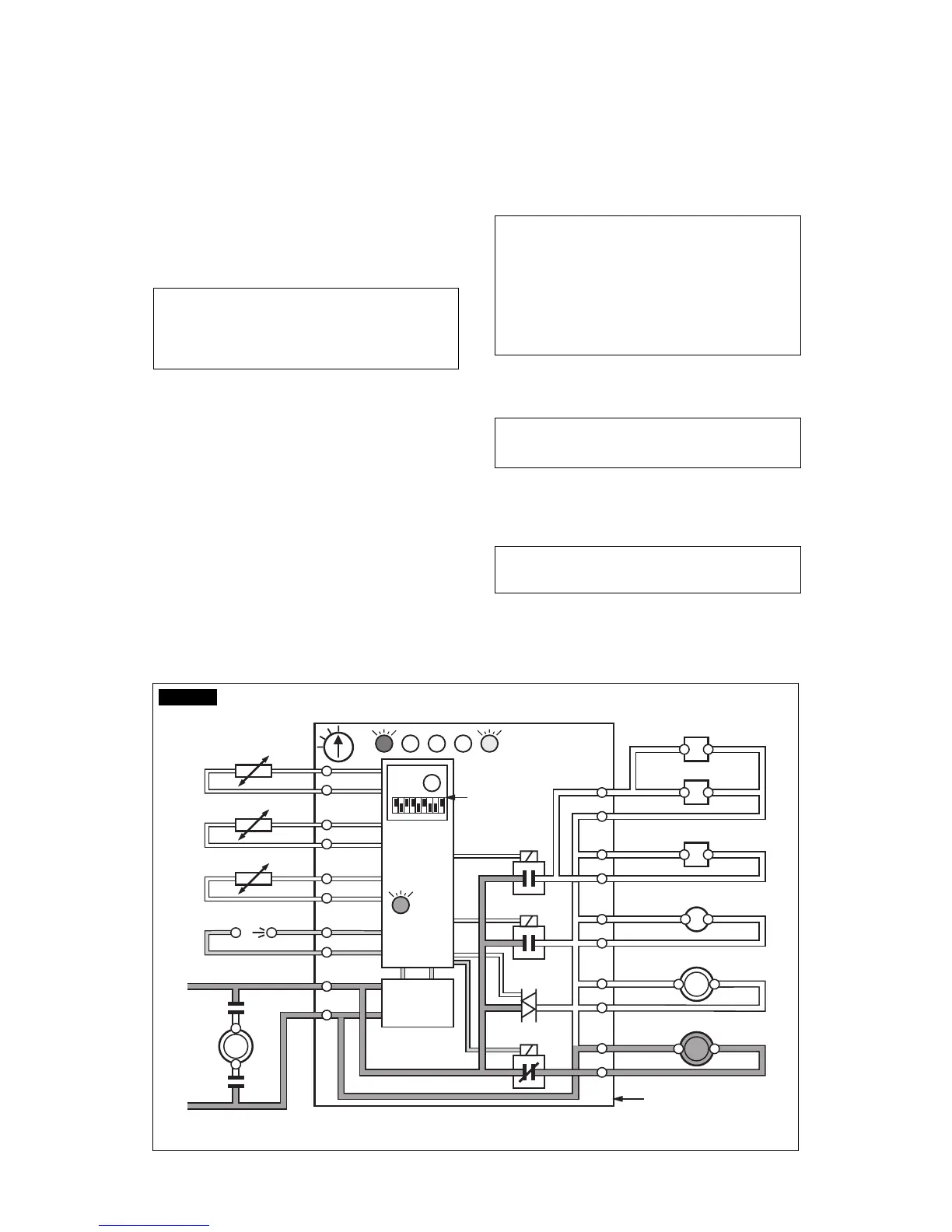

16

15

14

13

2

1

7

8

9

10

3

4

5

6

11

Rx Tx

WATER IN VALVE

HOT GAS VALVE

FAN MOTOR

WATER PUMP

- EVAPORATOR

- AMBIENT

- CONDENSER

TEMPERATURE SENSORSBINCOMPRESSOR

TRANSF.

DATA

PROCESSOR

ELECTR.

TIMER

DIP

SWITCH

ELECTRONIC CARD

L

N

RELAYS

RELAY

TRIAC

WATER DRAIN VALVE

CONTACTOR COIL

12

FIG. 8

Loading...

Loading...