TB-9009 Page 2 of 6

© 2016 DESCO INDUSTRIES, INC.

Employee Owned

SCS - 926 JR Industrial Drive, Sanford, NC 27332

East: (919) 718-0000 | West: (909) 627-9634 • Website: StaticControl.com

MOUNTING TO A GAS SUPPLY

When a gas supply is close to the work area and

fitted with a U.S. standard industrial interchange quick

coupling, you may attach it to the console directly using

the included female quick connect coupling. If a U.S.

standard industrial interchange quick coupling is not

available on the gas supply, be sure to use a suitable

interconnect between the gas supply and the console.

Use a prefilter as defined in the COMPRESSED GAS

REQUIREMENTS section if necessary.

ASSEMBLY

NOTE: Protect the hose from sharp objects, abrasion

and high temperatures. Do not pull or pinch the hose

while assembling the components.

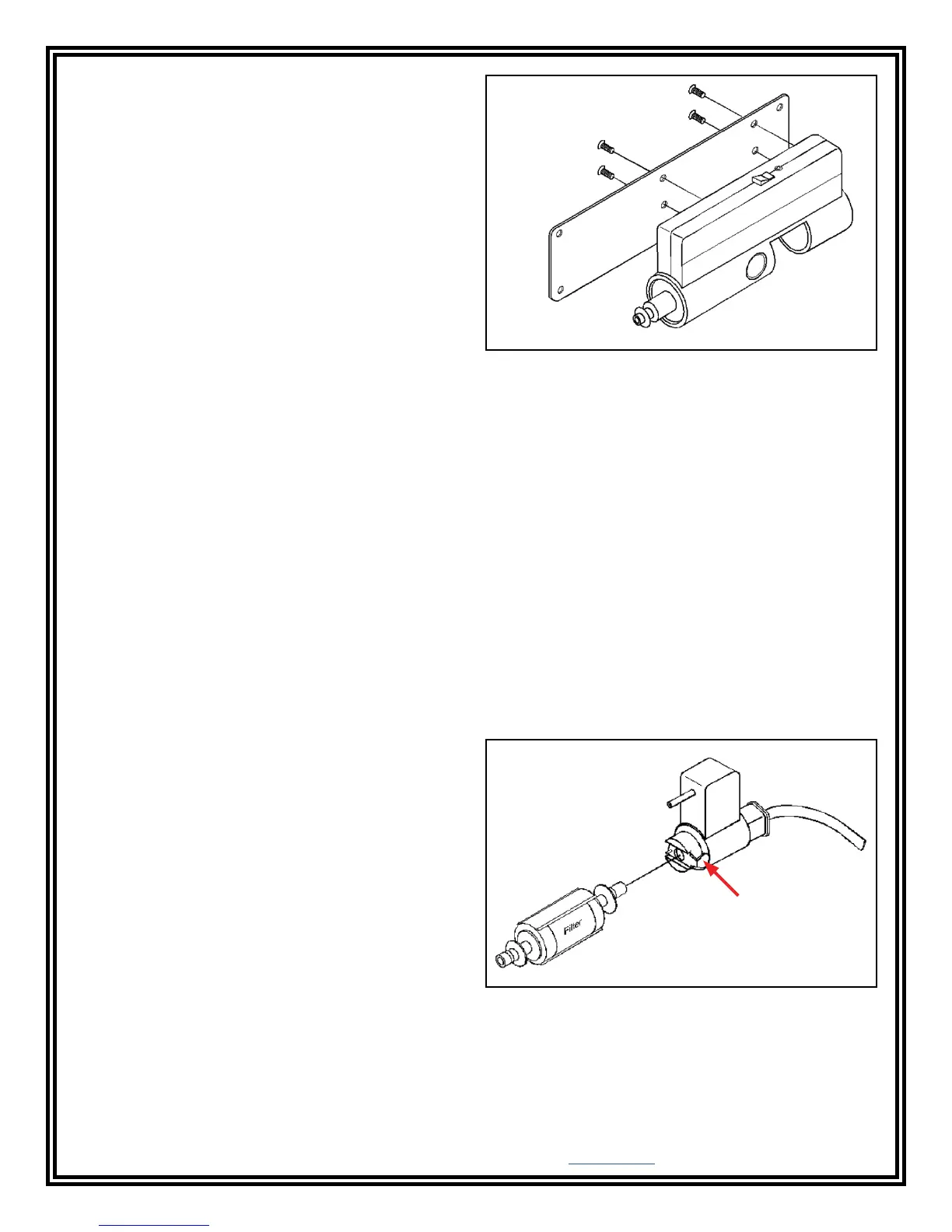

1. Insert the large end of the filter into the fitting at the

end of the flexible hose. Push the filter gently until

the metal release tab clicks and locks the filter into

place.

Installation

COMPRESSED GAS REQUIREMENTS

NOTE: Failure to use clean dry air or nitrogen may

result in damage to the Ionized Air Gun that is not

covered under the Limited Warranty.

The compressed gas supply must be clean dry air or

nitrogen supplied by a delivery system that utilizes

a refrigerated dryer or equivalent water removal to

achieve a limit of about 550 ppm water vapor at 35°F

(1.66°C) Dew Point. To prevent particles from entering

the console, a 2 micron coalescing filter or better is

recommended upstream of the gun console. Note that

the filter in the console collects small residual particles

and aerosols and does not act as a primary filter. The

console filter is rated at 0.01 micron for particulates and

is effective down to 0.008 micron for aerosols.

An adequate filter that can be recommended for the inlet

of the Ionized Air Gun would be a Finite Filter Grade 10

Media Specification. This provides a 95% coalescing

efficiency for aerosols with a 0.7 micron (and greater)

particle retention. This removes gross amounts of

particles, water and/or oil and aerosols.

A Grade 6 Media provides 99.98% efficiency when

almost total removal of liquid aerosols and particles are

required in all pressure ranges down to 0.01 microns.

Fine filters need to be changed more often.

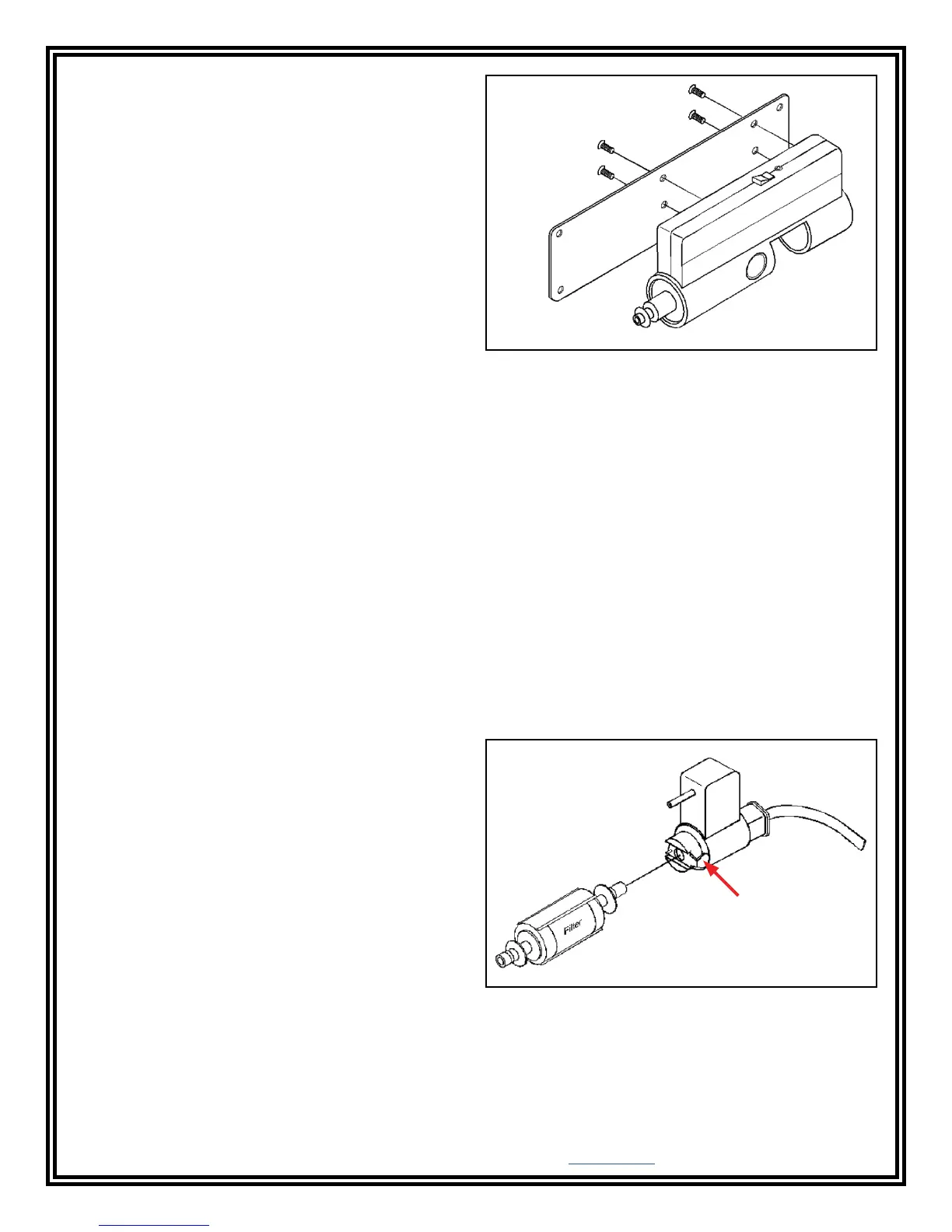

MOUNTING THE CONSOLE

Choose a location convenient to the work area and gas

supply. The console takes up very little space and is

adaptable to a variety of permanent or non-permanent

installations. To minimize bends in the Ionized Air

Gun’s hose, orient the console so that the open end

that accepts the filtered air hose to the hand unit points

toward the work area, and the male connector points

toward the gas supply.

Prior to mounting, plug the RJ-11 cable from the power

supply into the jack located on the back of the console.

Use the included screws to attach the mounting plate

to the threaded holes on the back of the console. Use

suitable screws and fasteners to attach the mounting

plate to a flat surface such as a wall or the back of a

workbench. When mounting to a hollow wall, be sure

to use adequate screws and wall anchors to ensure

stability of the installation.

Figure 2. Securing the console to the mounting plate

Point this end to

the gas supply

Figure 3. Connecting the air filter to the hose assembly

Metal release tab

Loading...

Loading...