3

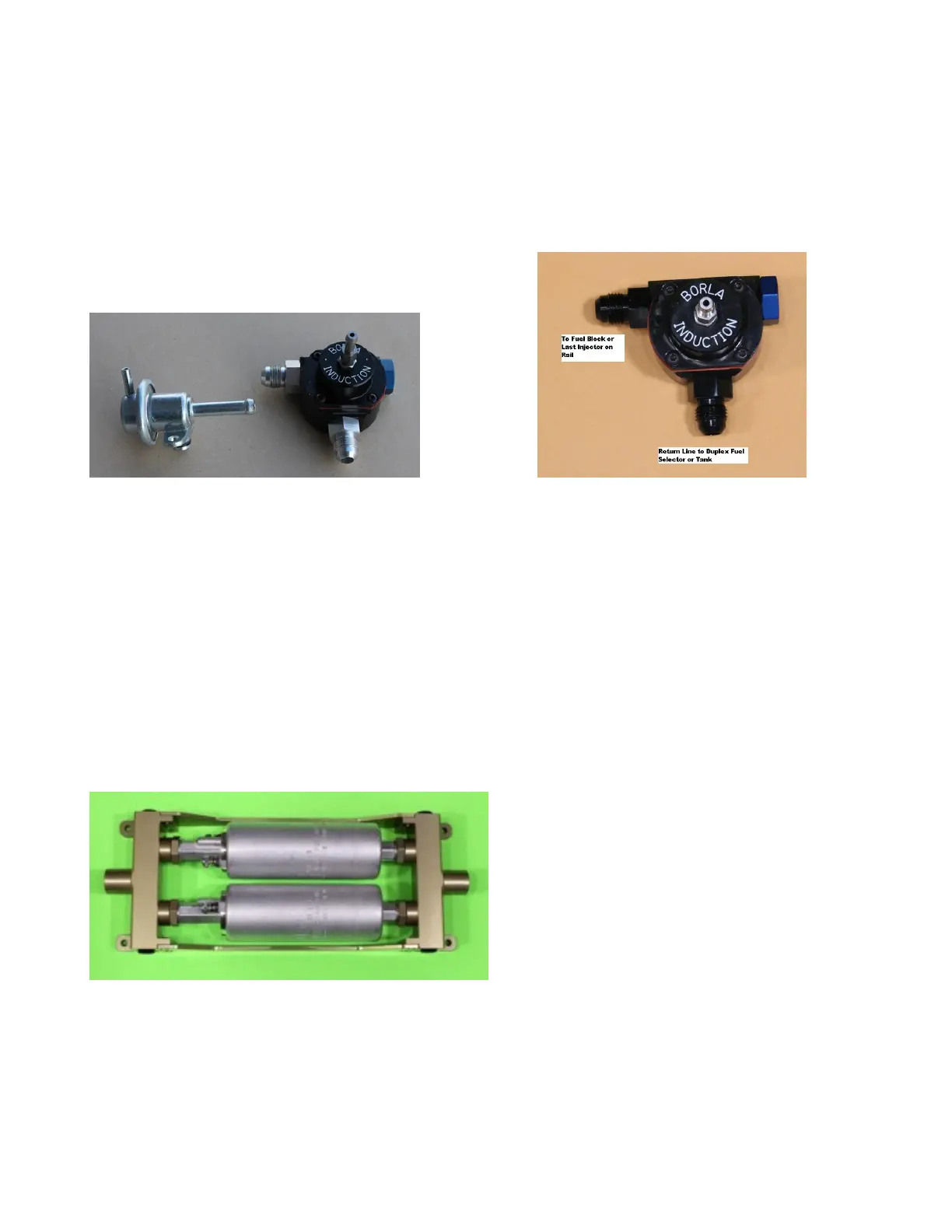

Fuel Pressure Regulator

We supply either an adjustable Borla regulator with AN-6 fuel fittings or a non-adjustable OEM type

with O-ring sealed inlet and either barb outlet or 1/8 or ¼ female NPT outlet fitting. We recommend

the adjustable type have its fuel pressure set to 45-50 psi using the adjusting screw on the top of

the regulator with the engine not running. Both regulator types have a MAP reference hose port for

connection to intake manifold vacuum. Using other unproven regulators is not recommended as

failure can cause partial or complete power loss. The adjustable regulator should be rigidly

mounted to the firewall.

Non-adjustable and AN6 adjustable fuel pressure regulators

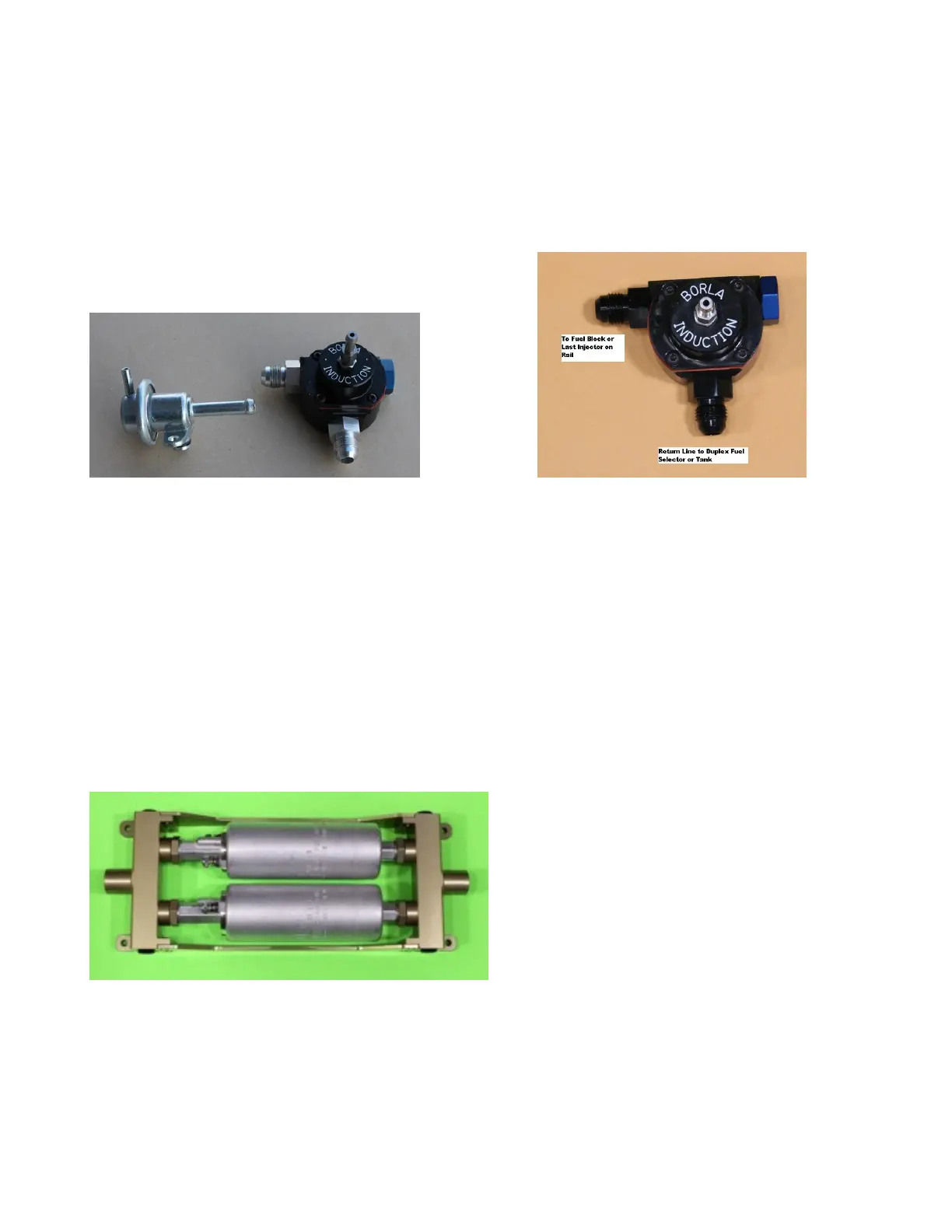

Fuel Pumps

We recommend using only the supplied/ recommended genuine Walbro pumps to ensure maximum

reliability and safety with regards to re-priming in the event of a dry tank condition and to be sure they

are properly matched to the hp of your engine. The use of other brands is not recommended as

failure can cause a partial or complete power loss condition.

We can supply either a single pump or dual pumps mounted in a module to allow easier plumbing and

mounting. Be sure to follow the safety/ assembly instructions that come with the pump

modules. Improper fitting assembly can cause line or pump blockage, leading to a partial or

complete power loss. Dual pumps should have separate power feeds, breakers and ground points

for maximum redundancy. Fuse each pump with a 15 amp fuse or breaker. Nominal current draw is

between 4.5 to 5.5 amps each at 14V, running at 45 psi pressure, depending on pump model.

Dual fuel pump module

On low wing aircraft, we recommend the pumps be mounted as low as possible on the floor,

preferably parallel to the floor. If you must mount the pumps vertically, mount them with the

outlets facing UP, never down. Inlet lines to the pumps should be 3/8 inch or AN6 with a minimum

number of fittings used. We recommend not using any 90 degree fittings if possible on the pump

inlets. Pump inlets should preferably be flooded by fuel at all times.

Loading...

Loading...