4

Never place fuel pumps close to any hot engine parts unless they have proper heat shielding/

cooling.

Fuel Lines

Fuel lines from the fuel tanks to fuel selector and pumps may be rigid aluminum or steel tubing or

Teflon lined, stainless steel braided flexible hoses. Flexible hoses must have a conductive inner

liner designed to limit static electricity buildup when carrying gasolines.

Fuel lines between the airframe and engine must be flexible types of at least medium pressure rating

(over 100 psi burst strength). Never use rigid line between the airframe and engine which can

lead to vibration breakages and fire hazard. Never place fuel lines close to any hot engine

parts unless they have proper heat shielding.

Some installations will route fuel from the pumps to a fuel block, then use separate braided hoses to

connect to each injector boss. In this case, fuel from the pump enters on end of the block and return

fuel exits the regulator on the other end of the block. Other installations will use a rail or loop type

system where each injector is linked in series to each other. In this case, fuel from the pump enters

the first injector and Tee fittings on each injector boss routes fuel to each remaining injector in turn.

The regulator is placed after the last injector in the loop and fuel is returned to the selected tank

through a Duplex fuel selector.

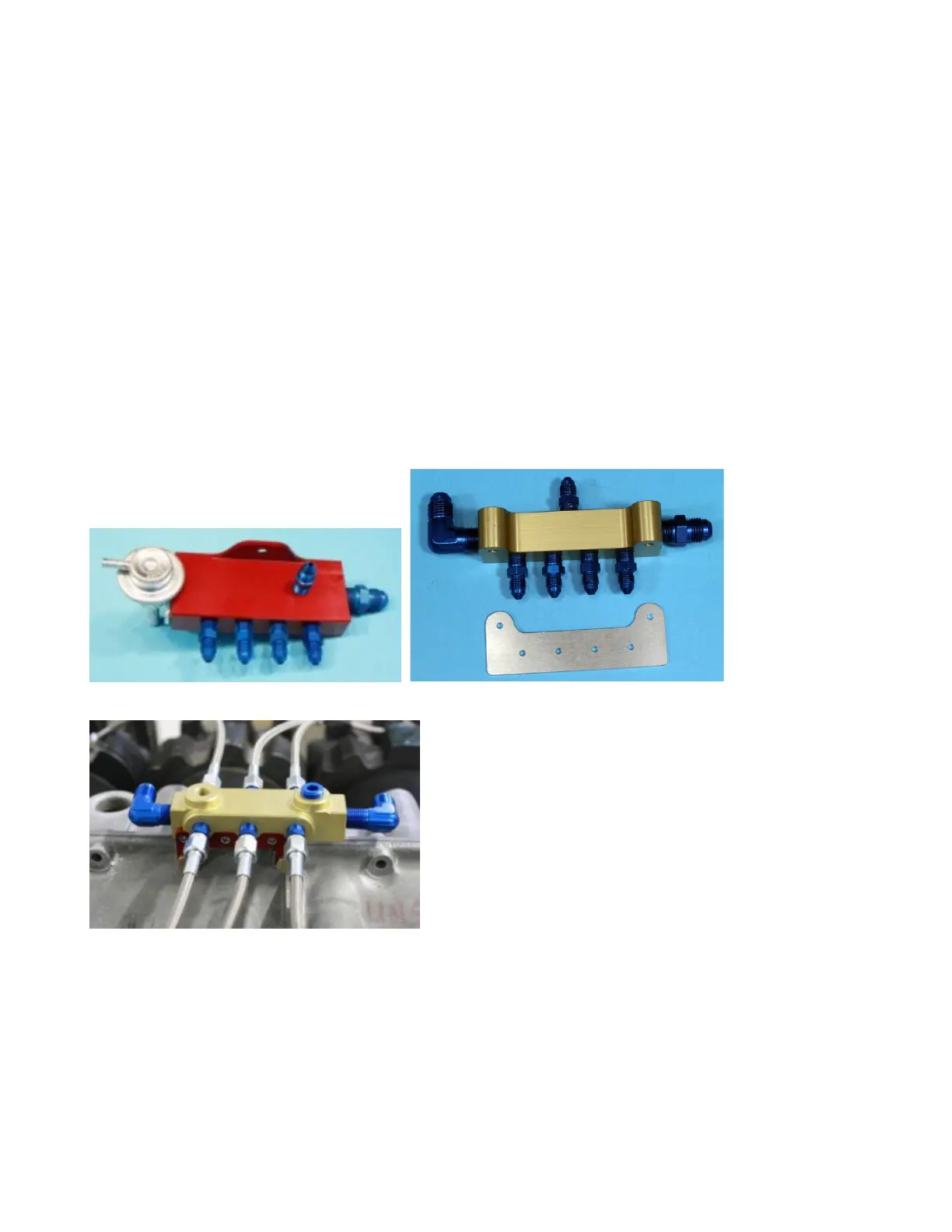

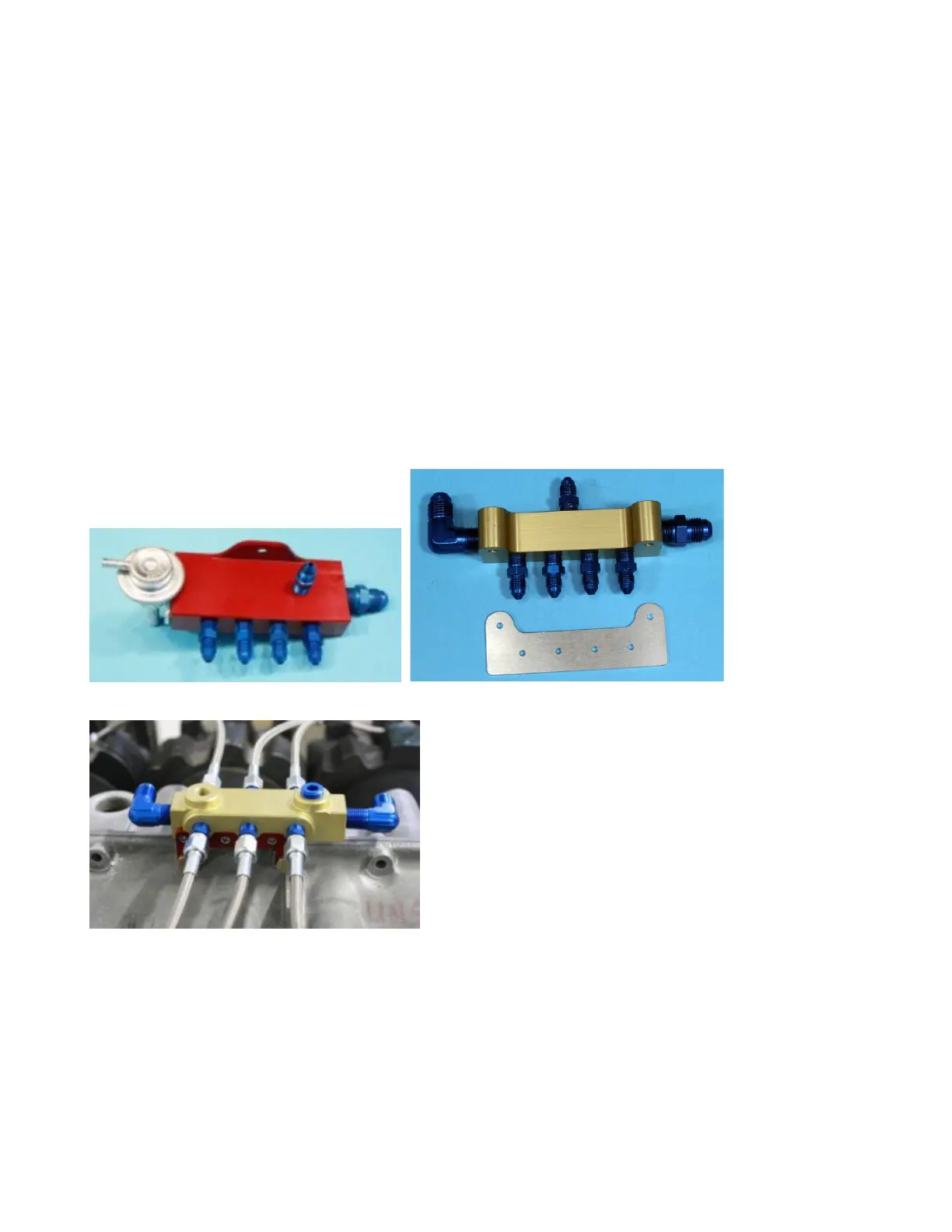

Fuel block with non-adjustable regulator Fuel block and template for rear baffle mounting

Top engine mount fuel block

You must use fuel return lines with SDS EFI. Fuel return lines have little or no pressure present.

Return fuel should enter the tank(s) at least 4 inches from where the fuel feed exits. Installation of

return lines into many tanks can be made in the access/ sender cover plate. Bulkhead fittings sealed

with Earls Stat-o-Seals on both sides can make installation easier in many cases. We recommend 3/8

or AN-6 return fittings and lines.

Loading...

Loading...