7

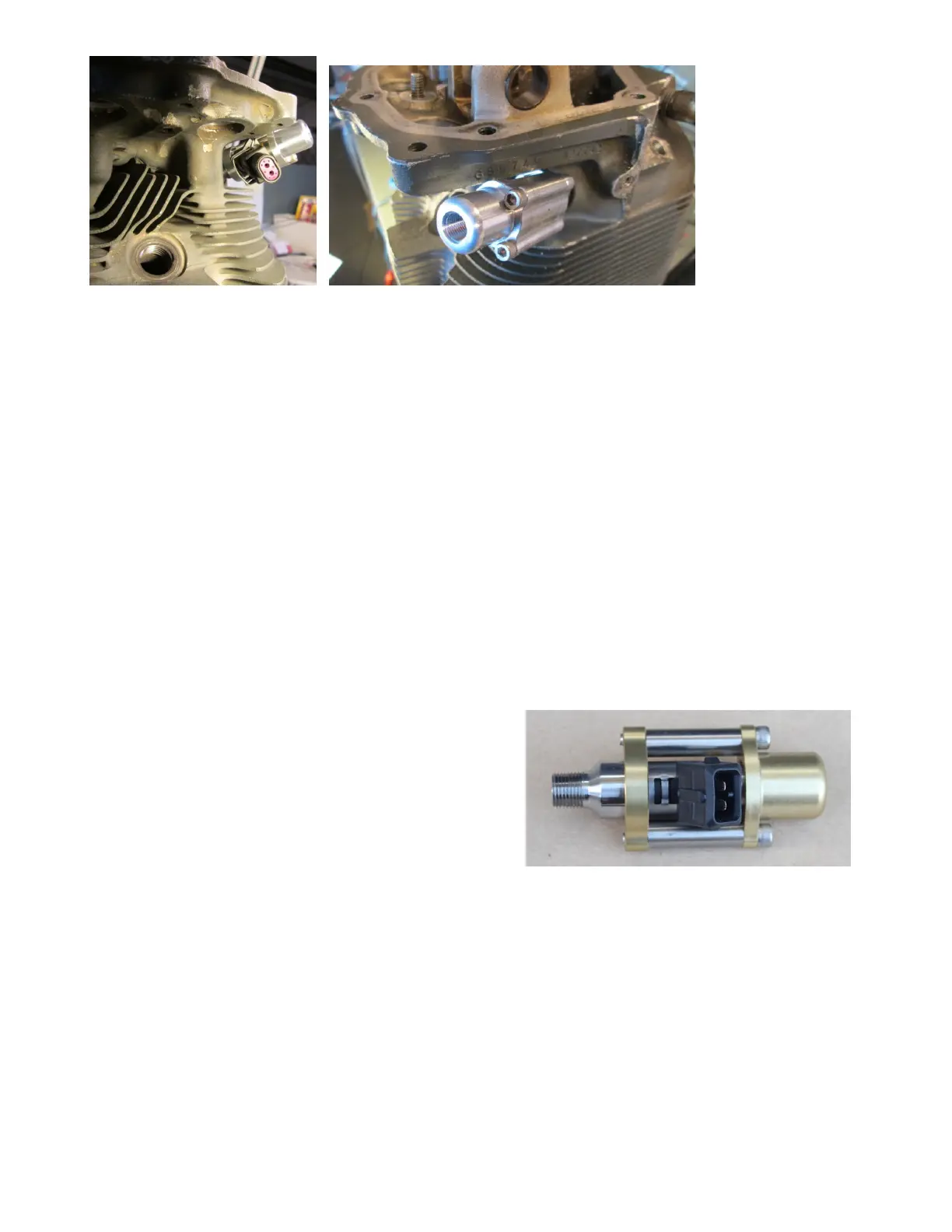

To mount these, remove the 1/8 NPT plugs from the injector ports (heat may be required). Slide the

gold flange over the lower silver adapter from below. Apply Loctite 246 to the threads on the silver

part and thread by hand into the injector port. Thread in until finger tight then tighten 1 to 1 ½ more

turns (approx 40-60 inch lbs.). You should get about 4.5 turns of thread engagement. Be careful here,

stripping the threads will be a very expensive exercise! Lubricate the lower injector O-ring and slide

the injector into the adapter. Rotate the injector so that the electrical plug faces towards the spark

plug. Lubricate the upper O-ring and slide the gold cap over the injector. Apply Loctite 246 on the

two 8/32 Stainless socket head cap screws as shown above and tighten in place.

We recommend –3 Stainless steel braided hoses to join the injector tops to the fuel blocks. The top

cap is threaded 1/8 NPT female. Apply pipe sealant (not Teflon tape) sparingly to the fitting (either

steel or aluminum) only, making sure not to get sealant on the first thread. Screw the fittings in at

least a ½ turn past finger tight to get it orientated towards the fuel block fittings. Never turn the fitting

backwards once you start screwing it in. Tighten the braided line swivel fitting in place being sure

that they do not touch any other parts and are supported from vibration at least on one point.

Lycoming Angle Valve Engines

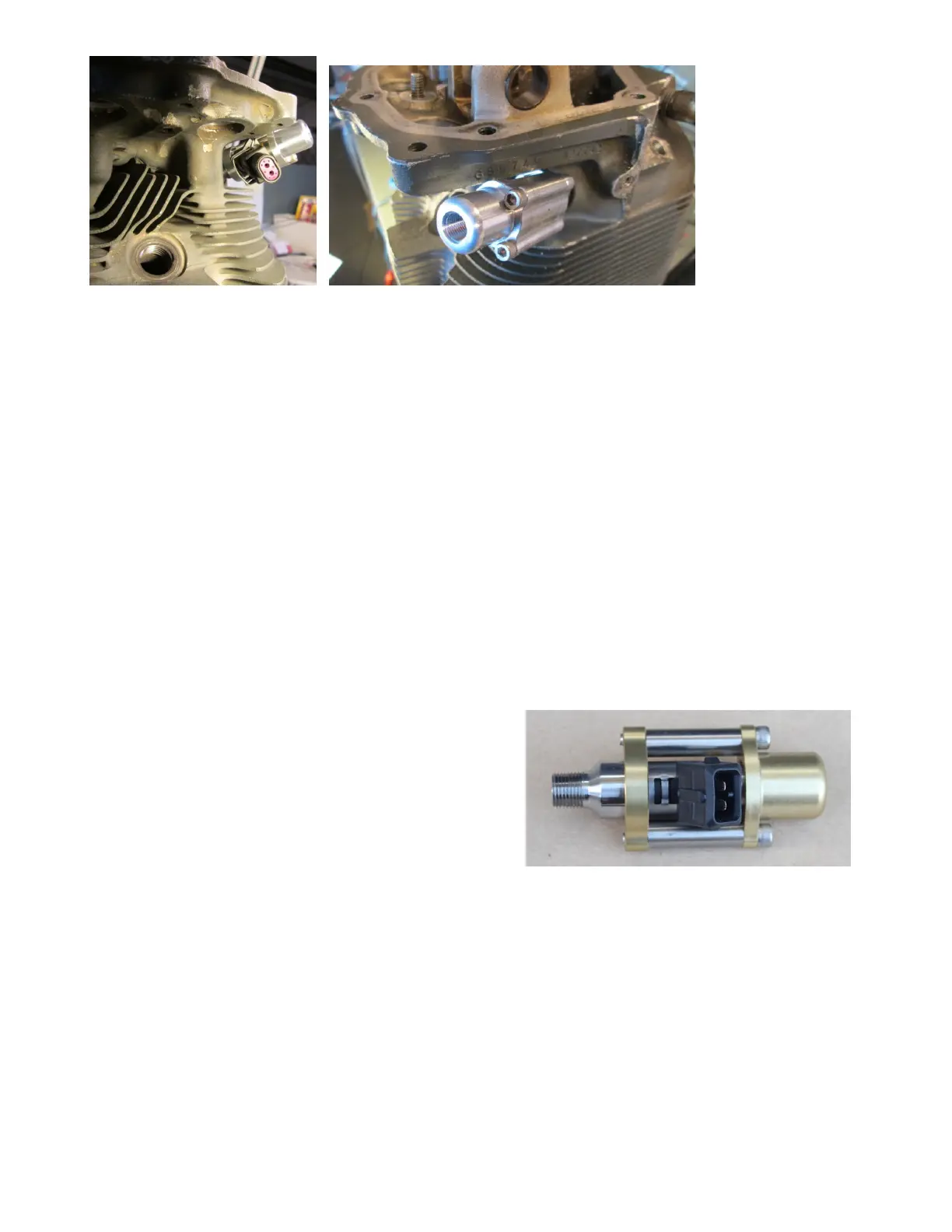

We supply a different adapter for AV engines but the threaded silver base and gold ring are installed

using the same procedure as above.

Once the base and ring are installed, lubricate the top

and bottom injector O-rings and slide the injector into

the lower base. We recommend you install 45 degree

AN fittings into the gold top cap prior to installing the

cap since you will not be able to tighten the fitting once

the cap is installed. Use pipe sealant on the fitting

threads as described above. Tighten and clock the

fitting so it’s perpendicular to the top cap flange holes

as shown below before installing the top cap assembly

to the injector.

Loading...

Loading...