WARNING! Before performing any maintenance operation,

switch off the compressor, disconnect from electricity

supply and release all air from the tank (except for 5.3.a)

5.1. Operations to be carried out after the first 50 working hours:

a) Check that all bolts/nuts are tight, particularly those

retaining the crankcase and cylinder head.

b) Replace the lubricating oil - see para 5.5.

5.2. Operations to be carried out weekly:

a) Drain condensation by opening the valve located under the

tank (fig.9). Place a container under the valve and open the

valve by turning anti-clockwise.

WARNING! Take care if there is still pressure inside the cylinder

as water could flow out with considerable force.

Recommended pressure 1 - 2bar max.

b) Check oil level and, if necessary, top up.

5.3. Operations to be carried out every 50 hours

(or more frequently, if the compressor operates in a very

dusty atmosphere):

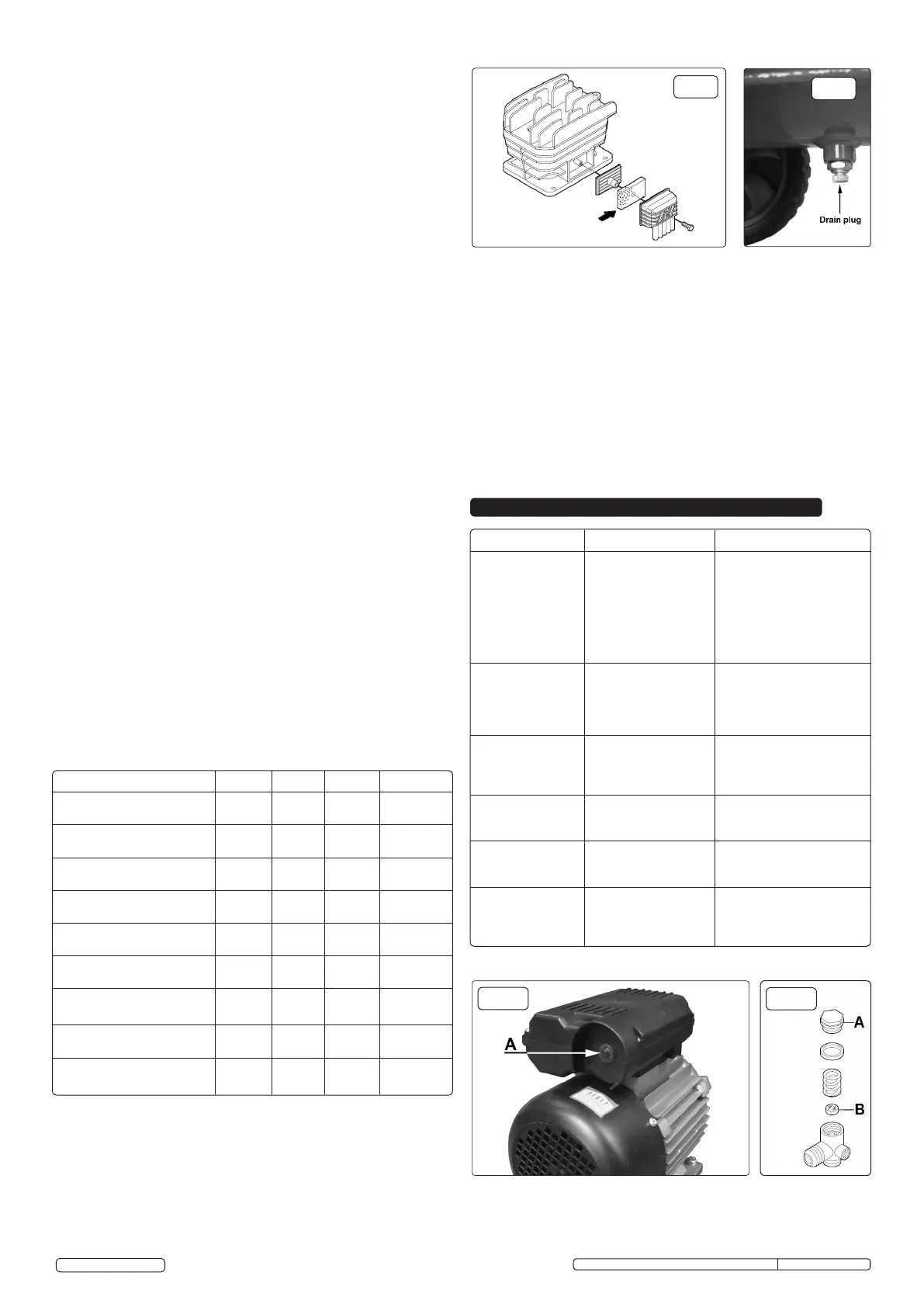

a) Remove the air filter element (fig.8). Using stored air from

the compressor's tank, clean the filter with compressed air.

(Wear eye protection and DO NOT direct air towards the

body or hands). DO NOT operate the compressor without

the filter as foreign bodies or dust could seriously damage

the pump. Replace the filter element and air filter housing.

b) Check for oil leaks.

5.4. Operations to be carried out every 100 hours:

a) Check the automatic cut-out at max. pressure and the

automatic cut-in at 2bar below.

5.5. Operations to be carried out every 400 hours:

a) Replace the lubricating oil. For oil specifications see 5.7.

Remove the filler/breather plug (see fig.4) then remove oil

drain plug, draining the oil into a container. Drain when the

compressor is hot so that the oil drains rapidly and

completely. Incline compressor to ensure complete

drainage. Replace oil drain plug and refill through the filler/

breather aperture. Do not overfill. Replace plug.

WARNING! Never mix different oils and do not use non-

detergent/low quality oils as the compressor may be

damaged.

WARNING! Dispose of waste oil only in accordance with

local authority requirements.

b) Replace air filter. (See fig.8)

c) Check all tube fittings and electrical connections.

d) Inspect pressure tank inside and out for damage or corrosion.

5.6. Maintenance Schedule

fig.9

Maintenance Operations Weekly 50hrs 100hrs 400hrs

Drain condensation

•

Check oil level

•

Clean intake filter

•

Check for oil leaks

•

Replace oil

•

Check cut-out

•

General cleaning of

compressor

•

Replace air filter

•

Check tube fittings and

electrical connections

•

5.7. Recommended oils

Synthetic oil suitable for temperatures ranging from -5°C to 45°C:

viscosity 5W50. We do not recommend using mineral oil in these

compressors.

Part No. Qty Description

FSO1 1ltr x 12 Compressor oil fully synthetic

FSO1S 1ltr x 1 Compressor oil fully synthetic

FSO5 5ltr x 1 Compressor oil fully synthetic

5.8. IMPORTANT WARNING - Air contaminants taken into the

compressor will affect optimum performance. Example: Body

filler dust or paint overspray will clog the pump intake filter and

may cause internal damage to pump/motor components. Please

note that any parts damaged by any type of contamination will

not be covered by warranty.

6. TROUBLE SHOOTING

Fault Cause Remedy

Pressure drop in the

tank.

Air leaks at

connections.

Run compressor to max.

pressure, switch off.

Brush soap solution over

connections and look for

bubbles. Tighten connections

showing leaks. If problem

persists contact Authorised

Service Agent.

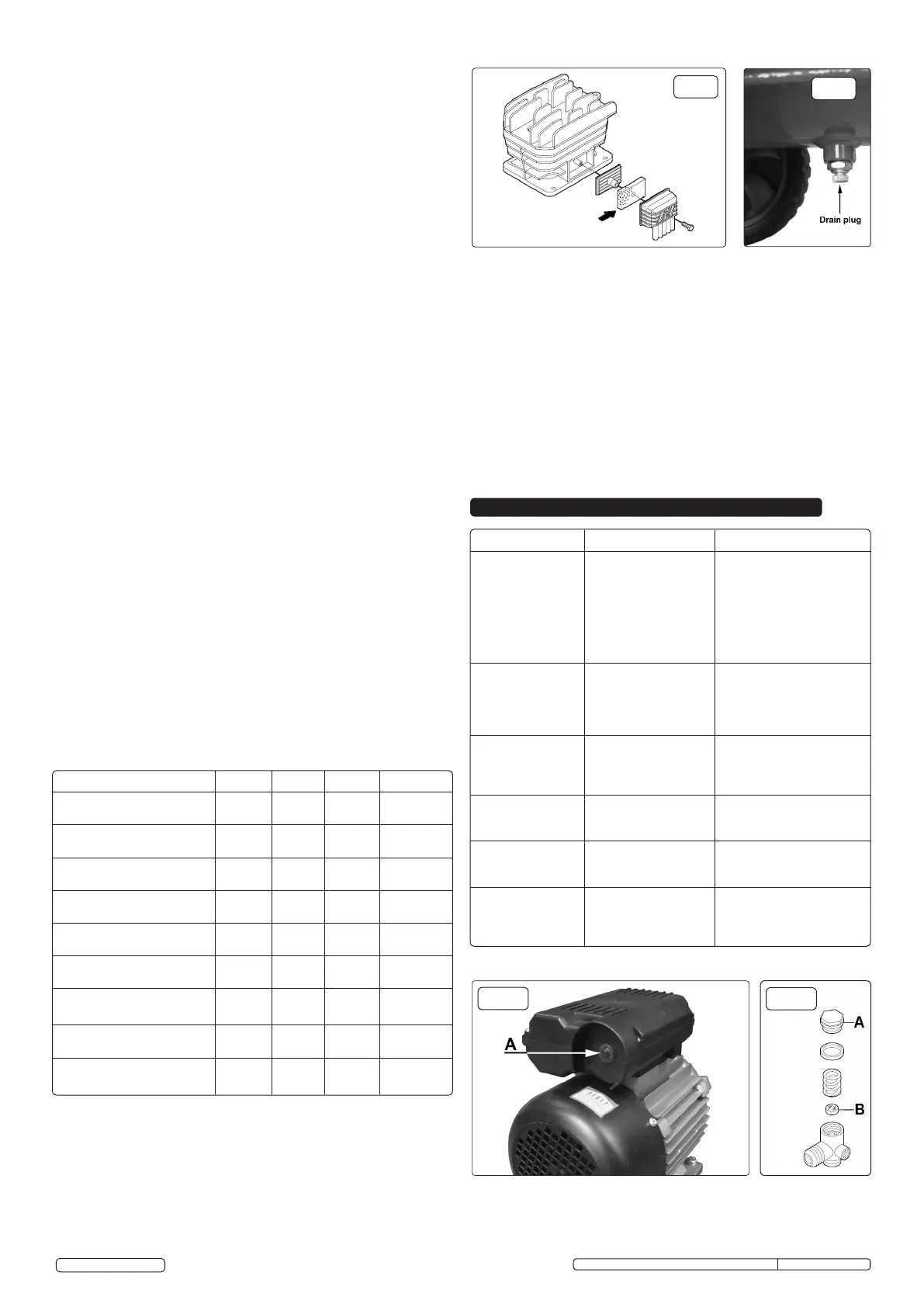

Pressure switch

valve leaks when

compressor is idle.

Non-return valve seal

defective.

Discharge all tank pressure.

Referring to fig.11, unscrew

valve cap 'A'. Clean rubber

disc 'B' and its seat. Refit all

parts accurately.

Compressor stops

and does not restart.

Power failure.

Motor failure.

Check electricity supply and

fuse.

Contact Authorised Service

Agent.

Compressor does

not stop at max

pressure.

Pressure switch fault. Contact Authorised Service

Agent.

Compressor does

not reach max

pressure.

Filter clogged.

Head gasket or valve

fault.

Replace filter element.

Contact Authorised Service

Agent.

Compressor noisy

with metallic knock.

Low oil level.

Bearing or piston

damage.

Turn off and top up oil

immediately.

Contact Authorised Service

Agent.

fig.8

fig.10

fig.11

Inspection of pressure tank both inside and out.

Under the PRESSURE SYSTEMS SAFETY REGULATIONS 2000 it is

the responsibility of the owner of the compressor to initiate a system of

inspection that both denes the frequency of the inspection and appoints

a person who has specic responsibility for carrying out the inspection.

Original Language Version

SAC2103B.V2, SAC2153B.V2, SAC2203B.V2 Issue: 1 - 30/10/13

© Jack Sealey Limited

Loading...

Loading...