6.

0 1 L PI

VO

T POINTS

Place several drops

of

S.A.E.

30

Oil

at points where

part

.s

move

aga

inst

each

other, especia

lly

:

a.

Fro

nt

Axle

Pivot (Fig. 20).

b. Hood Hinges.

c.

Foot

Pedal

Shaft (Fig.

9).

d.

Lift

Shaft Bushings (Fig. 33).

e.

P

olyf

oam

Seal

at

Variator

Pivot

Shaft (Fig. 16) (saturate

with

oil).

f.

Polyfoam

Seal

(behind

Flat

Idler)

at

Clutch Idler Pivot

Arm

(saturate

with

oil)

{Fig. 16).

g.

Clutch

Link

and Varidrive

Link,

see

page

22

, Key No's.

45an

d47.

h. Vari

dr

i

ve

Handle P

ivot

Bushing (Fig. 33).

EVERY

~@

HOURS

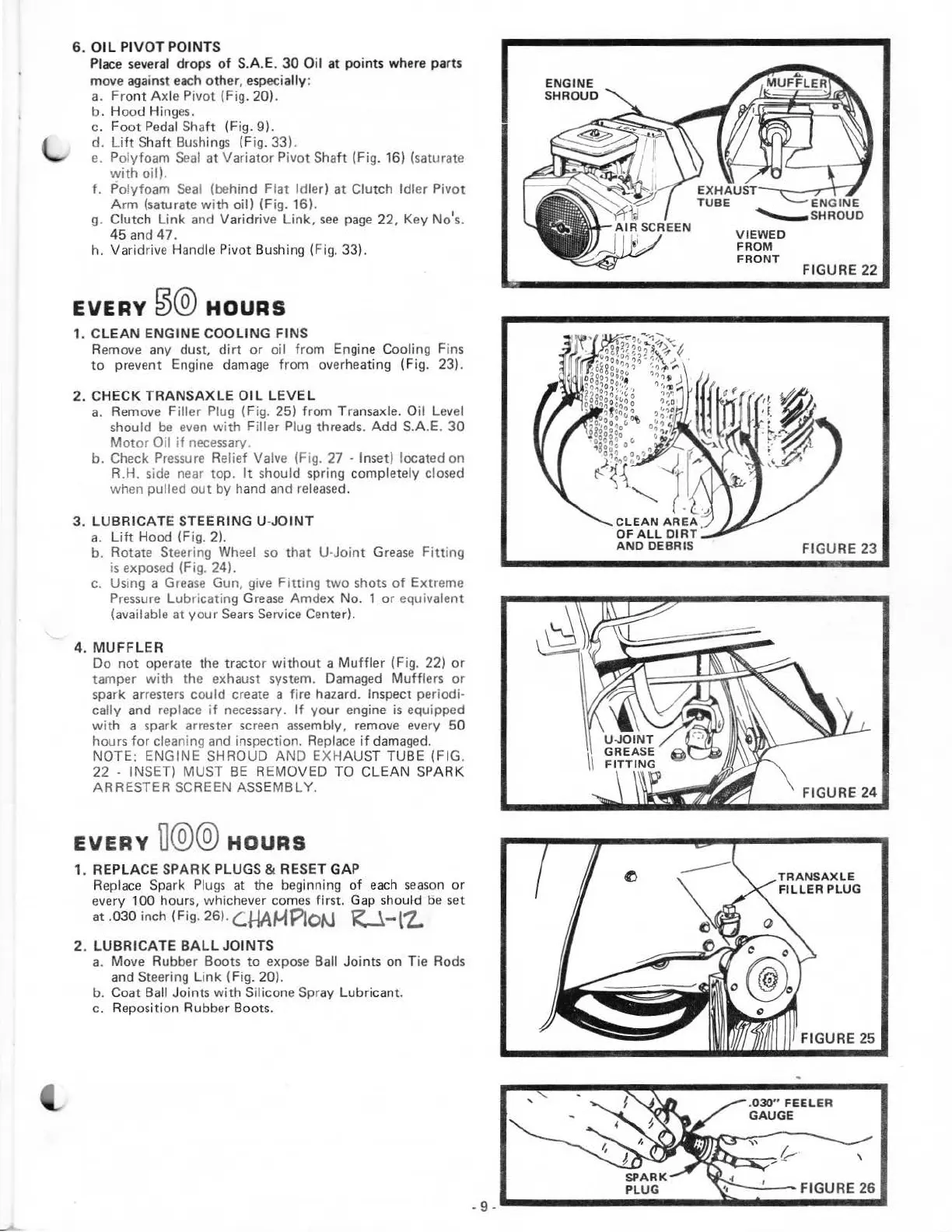

1. C

LEAN

ENGINE

COOLING

FINS

Remove any dust,

dirt

or

oil from Engine Cooling Fins

to

preve

nt

Engine d

amage

from overheating (F ig. 23).

2.

CHECK

TRANSAXLE

OIL

LEVEL

a.

Remove Filler Plug (Fig. 25) from Transaxle. Oil Level

should

be

even

with

F

ill

er Plug threads.

Add

S.A.E.

30

Motor

Oil

if

necessary.

b.

Check

Pressure

Rel

ief

Valve

(F1g.

27 · Inset) located on

R.H. side near top.

It

should spring completely closed

when pulled

out

by

hand

and

released

.

3. L

UB

RICATE

STEERING U-

JOINT

a.

Lih

Hood (Fig. 2).

b. Rotate Steering Wheel so

that

U·Joint

Greas

e

Fitting

is

exposed (Fig. 24).

c.

Using a

Grease

Gun, give

Fitting

two

shots

of

Extreme

Pressure

Lubricating

Grease

Amdex No. 1

or

equivalent

(available at

your

Sears

Service Center).

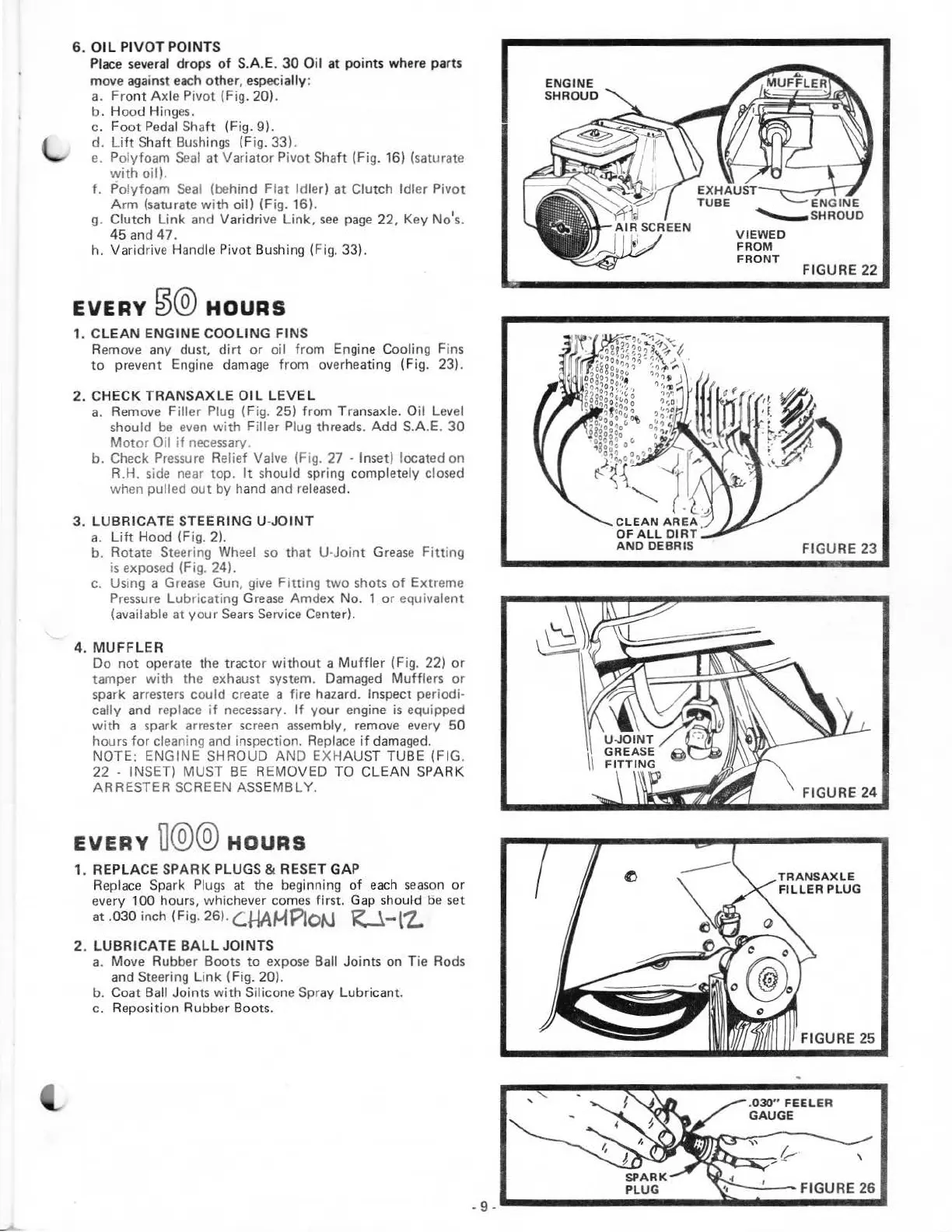

4.

MUFFLER

Do

not

operate the tractor

without

a

Muffler

(Fig. 22)

or

tamper

with

the exhaust system. Damaged

Muff

lers

or

spark arresters could create a fire hazard. Inspect periodi·

cally and replace

if

necessary.

If

your

engine

is

equipped

with

a spark arrester screen assembly, remove every 50

hours

for

cleaning and inspection. Replace

if

damaged.

NOTE: ENGINE SHROUD

AND

EXHAUS

T TUBE (FIG.

22

· INSET) MUST

BE

REMOVED TO

CLEAN

SPARK

ARRESTER SCREEN ASSEMBLY.

EVERY

D@@

HOURS

1. REPLACE

SPARK

PLUGS & RESET GAP

Rep

l

ace

Spark

Plugs

at the beginning

of

each

season

or

every 100 hours, whichever comes first. Gap should be set

at

.030 inch (Fig. 26).

C.HA~Plo~

R-.1-l'Z.

2.

LUBRICATE

BALL

JOINTS

a.

Move Rubber Boots

to

expose Ball Joints on T

ie

Rods

and Steering L

ink

(Fig. 20).

b. Coat Ball Joints with Silicone Spray Lubricant.

c.

Rep

os

ition Rubber Boots.

ENGINE

SHROUD

VIEWED

FROM

FRONT

FIGURE

22

FIGURE

23

FIGURE

24

TRANSAXLE

FIL

LER PLUG

FIGURE

25

another free manual from www.searstractormanuals.com

Loading...

Loading...