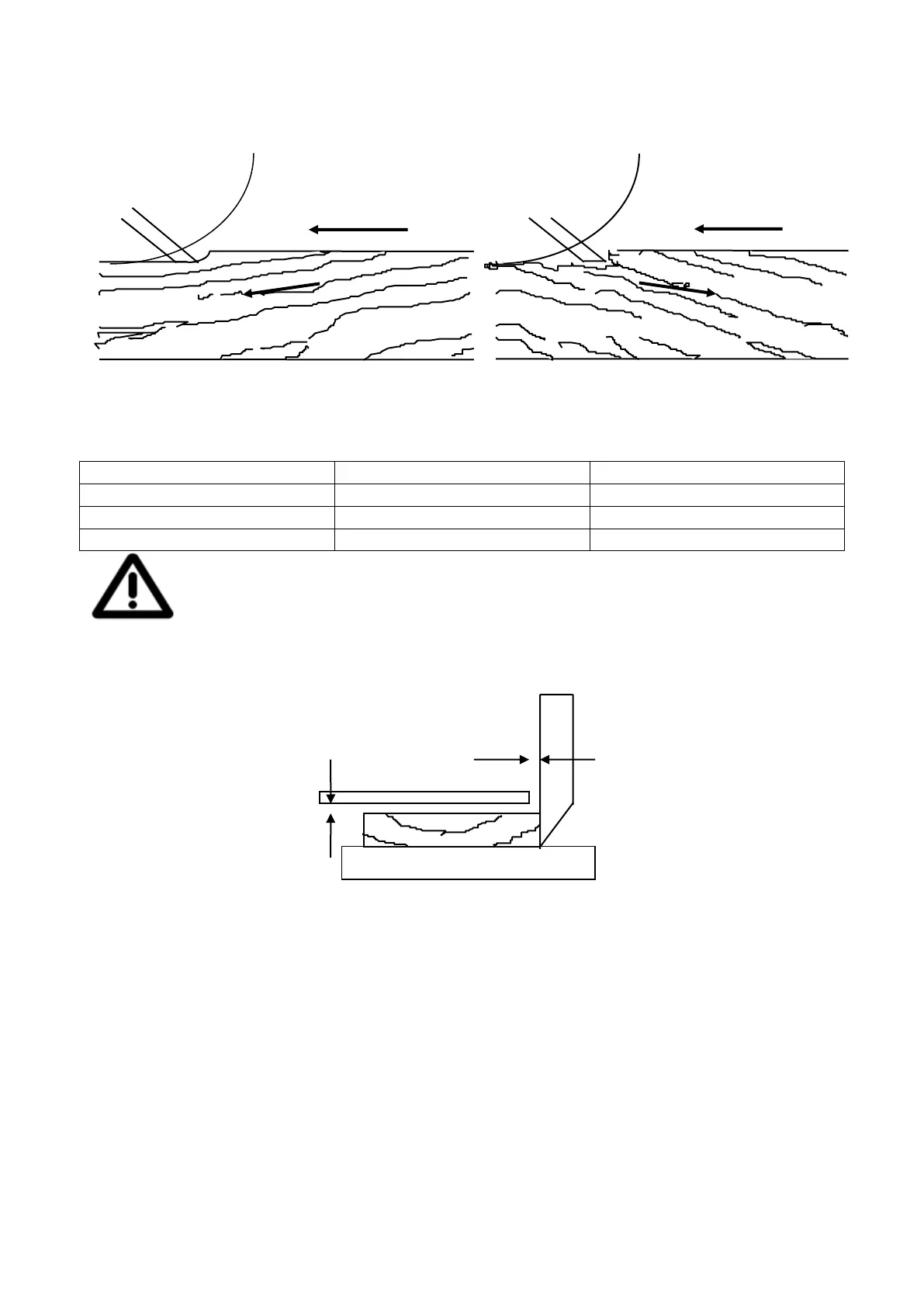

ragged finish. Always feed with the grain running down towards the front of the table when

in the planing mode, and the opposite when thicknessing.

Correct Incorrect

Feed Feed

Slope of grain

Slope of grain

9.1 Flatting

Workpiece dimensions:

Only work with a push stick

Extn rollers or 2

nd

person reqd

Max 308 (MB) or 410mm (CP)

If a workpiece is smaller than 10mm it may split if the depth of cut is too large

(4mm). The finished planed workpiece must not be thinner than 6mm.

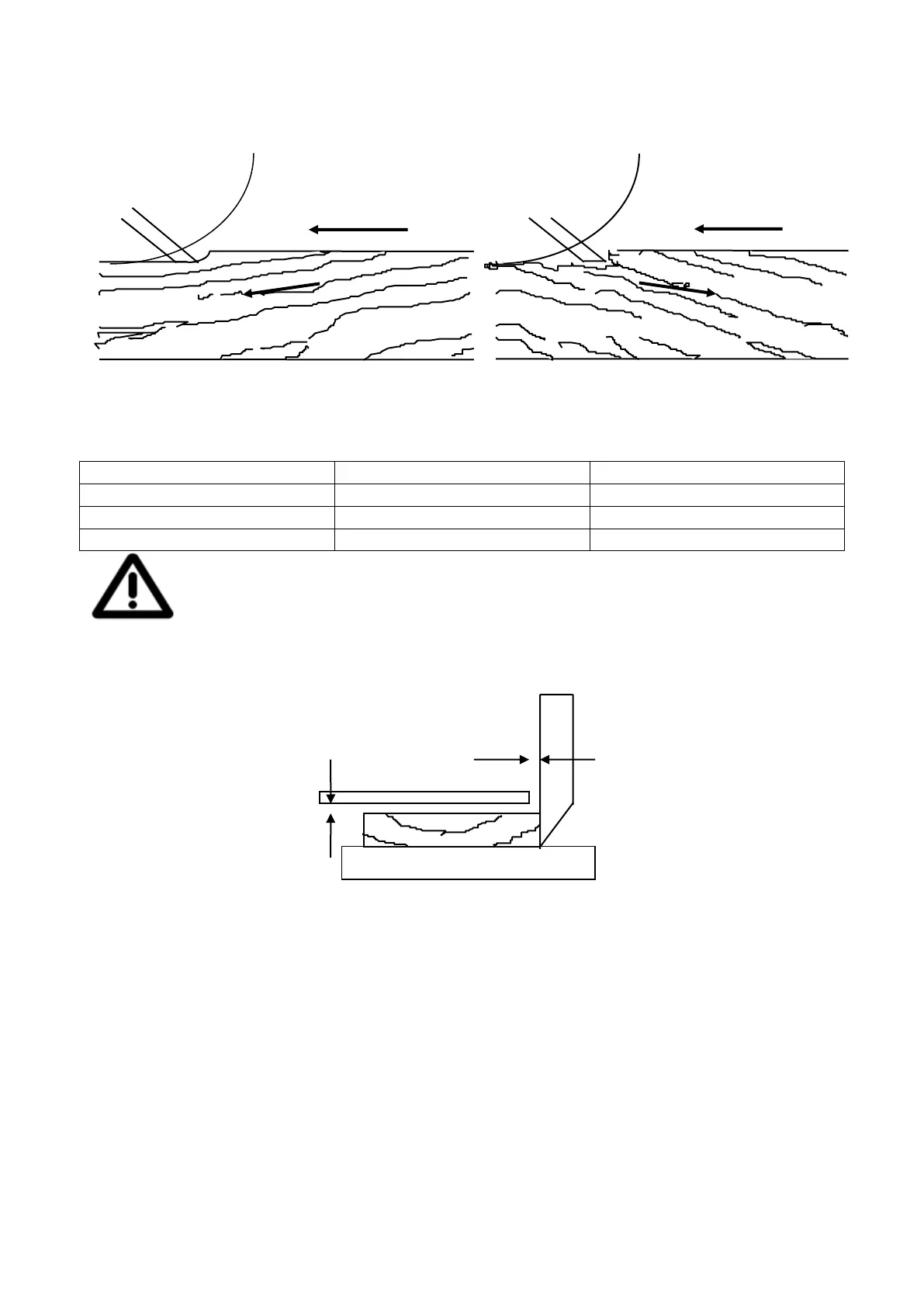

When flatting, the wood is passed below the bridge guard, which should be within 10mm of the

timber and 10mm of the fence, as shown below:

10mm

Bridge Guard

10mm

Workpieces longer than the in and out-feed surfacing tables should be supported, e.g. by

extension tables or roller supports. Unless very thick material is being planed, flatting should be

the safest of operations on a hand fed planer, provided that all necessary precautions are taken.

In an attempt to justify the incorrect use of the bridge guard (many wrongly pass the timber

between the end of the guard and the fence) machinists often assert that the left hand has to

jump the guard as the wood is passed over the cutters, the consequent interruption in the

progress of the cut preventing the production of accurate work. It is also claimed that the left

hand must exert pressure on the wood immediately over the cutterblock. Only in the case of

flatting short pieces of wood might it be necessary to pass the wood between the end of the

bridge guard and the fence in order to maintain adequate control. In this event, the wood should

be fed up and over the cutters by means of a push block as described in the relevant section of

Loading...

Loading...