12.1 Noise

Noise levels can vary widely from machine to machine depending on conditions of use. Persons

exposed to high noise levels, even for a short time, may experience temporary partial hearing

loss and continuous exposure to high levels can result in permanent hearing damage. The

Woodworking Machines Regulations require employers to take reasonably practicable measures

to reduce noise levels where any person is likely to be exposed to a continuous equivalent noise

level of 90 dB(A) or more over an 8 hour working day. Additionally, suitable ear protectors must

be provided, maintained and worn.

Machines identified as generating unhealthy noise levels should be appropriately marked with a

warning of the need to wear hearing protection and it may be necessary to designate particular

areas of the workplace as ‘Ear Protection Zones’. Suitable warning signs are specified in the

Safety Signs Regulations 1995. It may be necessary to construct a suitable enclosure, in which

professional advice should be sought.

Further information and references to practical guidance are contained in free leaflets available

from The Health & Safety Executive.

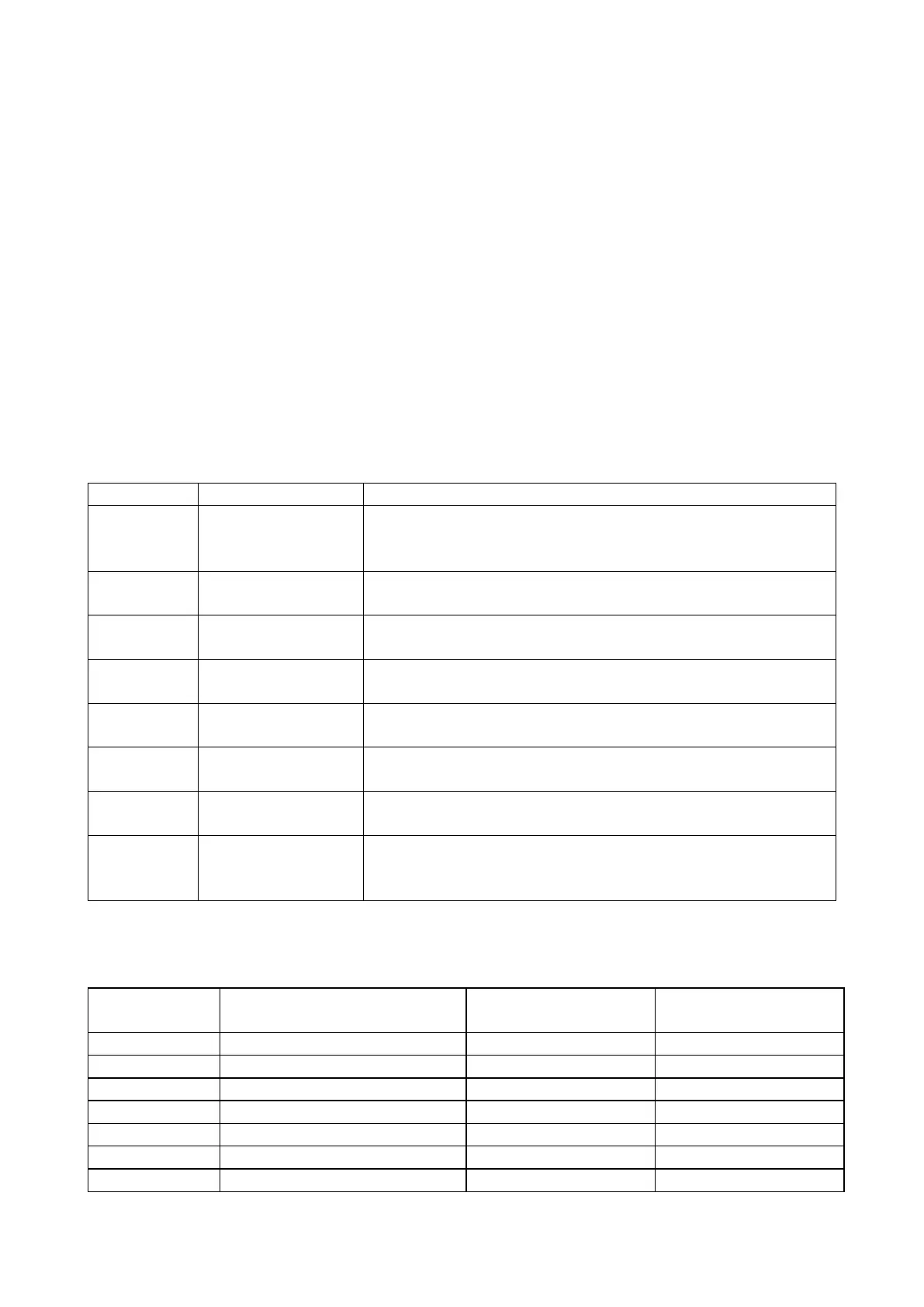

The list below outlines some of the variables that directly affect the noise level of the machine:

Hard stiff timber can mean more noise (approx. 2dB(A)

difference when cutting oak and pine) & more transmitted

noise.

Wide work pieces radiate noise over a greater area

increasing the noise level.

Thin workpieces generally vibrate more increasing the

noise level.

Long workpieces transmit noise away from the cutting area

towards the operator.

This affects the windage noise and increases roughly in

proportion to the width of cut.

Dull and worn blades exert more force on the timber thus

creating more noise.

Out of balance blades mean vibration and changes in

cutting conditions, resulting in increased noise levels.

Air Velocity/

System Design

Resonant conditions can lead to high noise levels,

excessive turbulence and chip impact can increase noise

levels substantially.

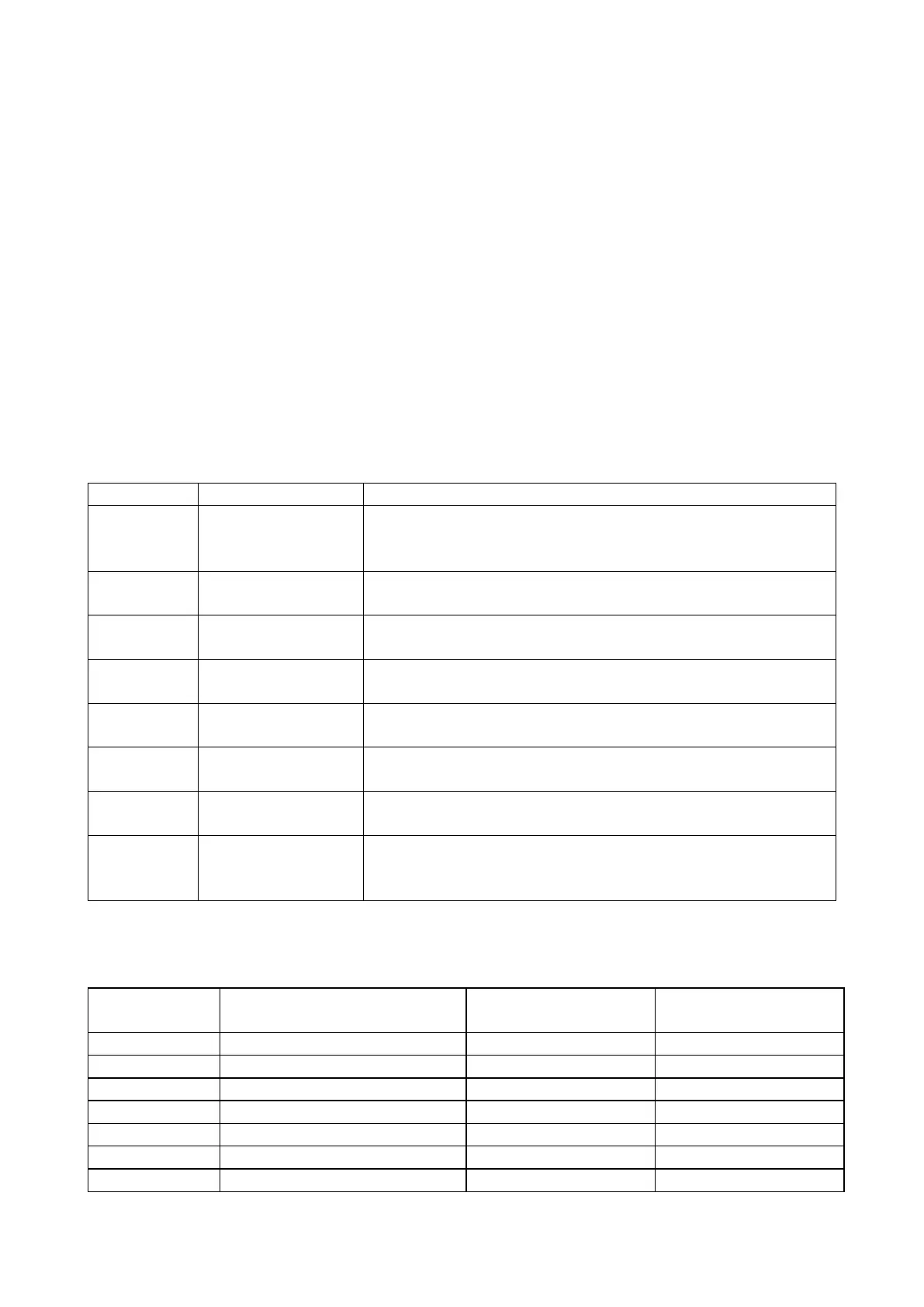

The following noise levels were recorded at a distance of one metre from the machine (operator

side), using varying feed rates and depths of cut.

Loading...

Loading...