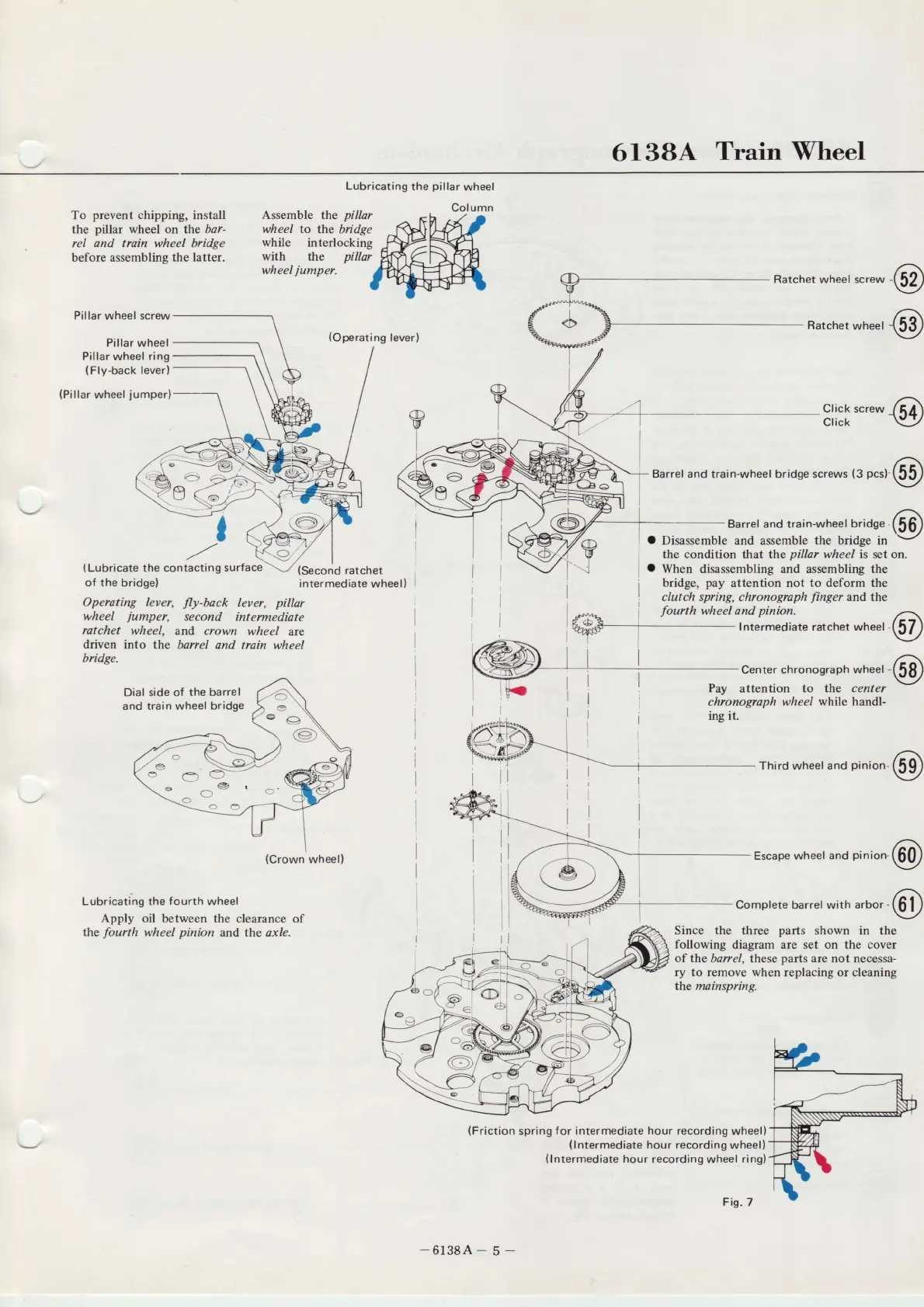

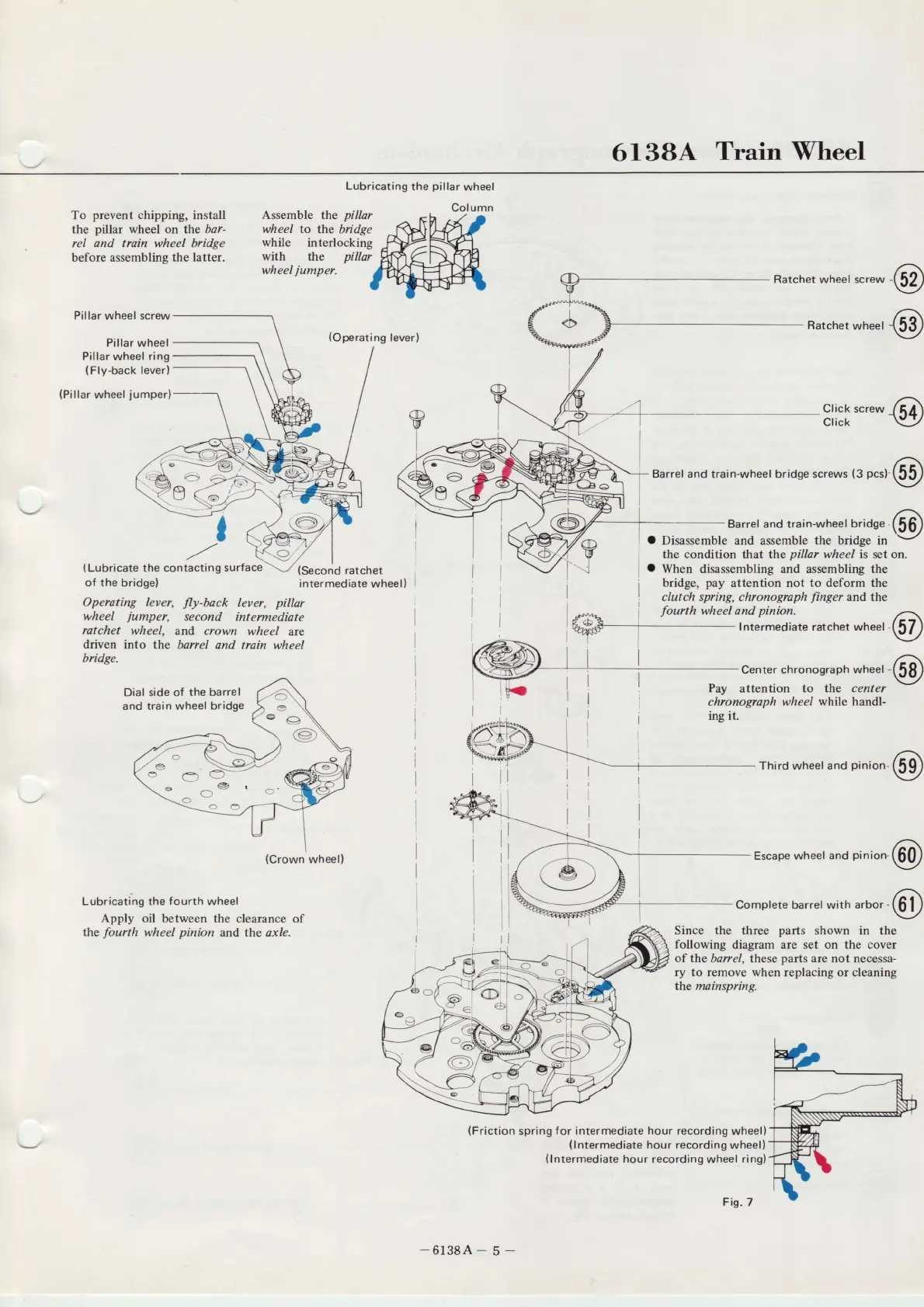

6138ATrainWheel

Lubricating

the

pillar

wheel

Column

To

prevent

chipping, install

the

pillar

wheel on the bor-

rel and train wheel bridge

before assembline the

latter.

Pillar

wheel screw

Pillar wheel

Pillar wheel

ring

(Fly-back

lever)

(Pillar

wheel

jumperl

Assemblethe″ rr4″

″力′

′

′

tothebガ

確

e

wh■ ehterlocking

withthe

′

r7ar

wheel

jumper.

fly-back

lever,

pillar

second

intermediate

and, crown

wheel

arc

barrel

and

train wheel

(Operating

lever)

・

⑫

①

s

c

r

e

w

w

h

e

e

l

w

h

e

e

⁝

a

t

c

h

e

t

e

t

R

R

a

t

c

h

一

瓦sぉ

"mЫ

eTI芯i「鷲壕

躍

i①

/

(Lubricate

the contacting

surface

of the

bridge)

Operating lever,

wheel

iumper,

ratchet

wheel,

driven

into the

bridge.

①

・

①

r

e

w

p

c

S

S

C

に

the condition that the

pillar

wheel is set on.

O

When disassembling and assembling the

bridge,

pay

attention not to deform the

clutch spring, chronogmph

jlnger

and the

Lubricating the

fourth

wheel

Apply oil between

the clearance of

the

fourth

wheel

pinion

and the axle.

①

①

{Friction

spring

for intermediate hour recording

wheel}

(

| ntermediate hour recordin

g

wheell

(lntermediate

hour recording wheel

ring)

呻

―

ギ

竺里

7∫

懲

tけ

attad

①

Center chronograph

wheel

-

Pay

attention

to the center

c hro nograph whe el whlle handl-

ing it.

dwttdttd画

m①

││

│

Escape wheel

and

pinion-

Complete barrel with

arbor

Since the three

parts

shown in the

following

diagram are set on the

cover

of the

barrel, these

parts

are not necessa-

ry

to

remove

when replacing or cleaning

the mainspring.

Dial

side of the barrel

and train wheel bridge

(Crown

wheel)

ミ

〇

〇

〇 =

■

‑6138A‑5‑

Fig.7

Loading...

Loading...