6. VENT LOCATION AND ENCLOSURES

SELKIRK TYPE B GAS VENTS ARE RECOMMENDED TO BE INSTALLED WITHIN THE HEATED

PORTION

OF THE STRUCTURE WHENEVER POSSIBLE TO REDUCE HEAT LOSS WHICH MAY IN TURN

LEAD

TO POOR DRAFT AND/ OR CONDENSATION/ ICING PROBLEMS.

If an exterior location is necessary, Selkirk Type B Gas Vent must be:

- Enclosed by a chase spaced out 2” from the vent at least to the roof line.

- The enclosure should be caulked to prevent entry of moisture.

- It is also recmommended that

the chase be insulated up to a

maximum of R-12 (RSI 2.1).

- Exposed insulation shall be of

the rigid type. Non rigid type

must be supported so that the

insulation does not come in

contact with the vent.

- The bottom of the enclosure

must be closed off.

- It is recommended to provide

an access panel for future

inspection and cleaning.

Appliances served by an

exterior gas vent must have an

air supply to the appliance room

adequate to balance indoor and

outdoor pressures. Otherwise,

“stack action” of the heated

building can cause reverse

venting action when the

appliance is off, or operating on

its pilot.

In multi-family residential, high

rise and many other types of

buildings, codes specify that

vents must be located in fire-

rated shafts or chases. Building

code requirements in such cases

must be carefully followed with respect to wall construction, access,

clearance, support, initial penetration of breaching, and method of termination.

7. FIRE STOPPING

All Type B Gas Vents passing through floors, ceilings or walls must be

firestopped using 26 gauge or heavier galvanized steel. (See Fig. 5 and 6)

The fire stop must close the area between the outer wall of the pipe and the

opening in the structure. In areas such as attics with no floor, the fire stop

should be placed on top of a properly framed opening. KEEP WIRES AND

INSULATION OUT OF REQUIRED AIR SPACE AROUND GAS VENT.

Fire stops may be used as vent pipe supports. See Section 10. For gas vents

within a shaft or chase, firestopping is provided by the vertical walls of the

shaft. Any openings in the chase/ shaft below the roof must be firestopped.

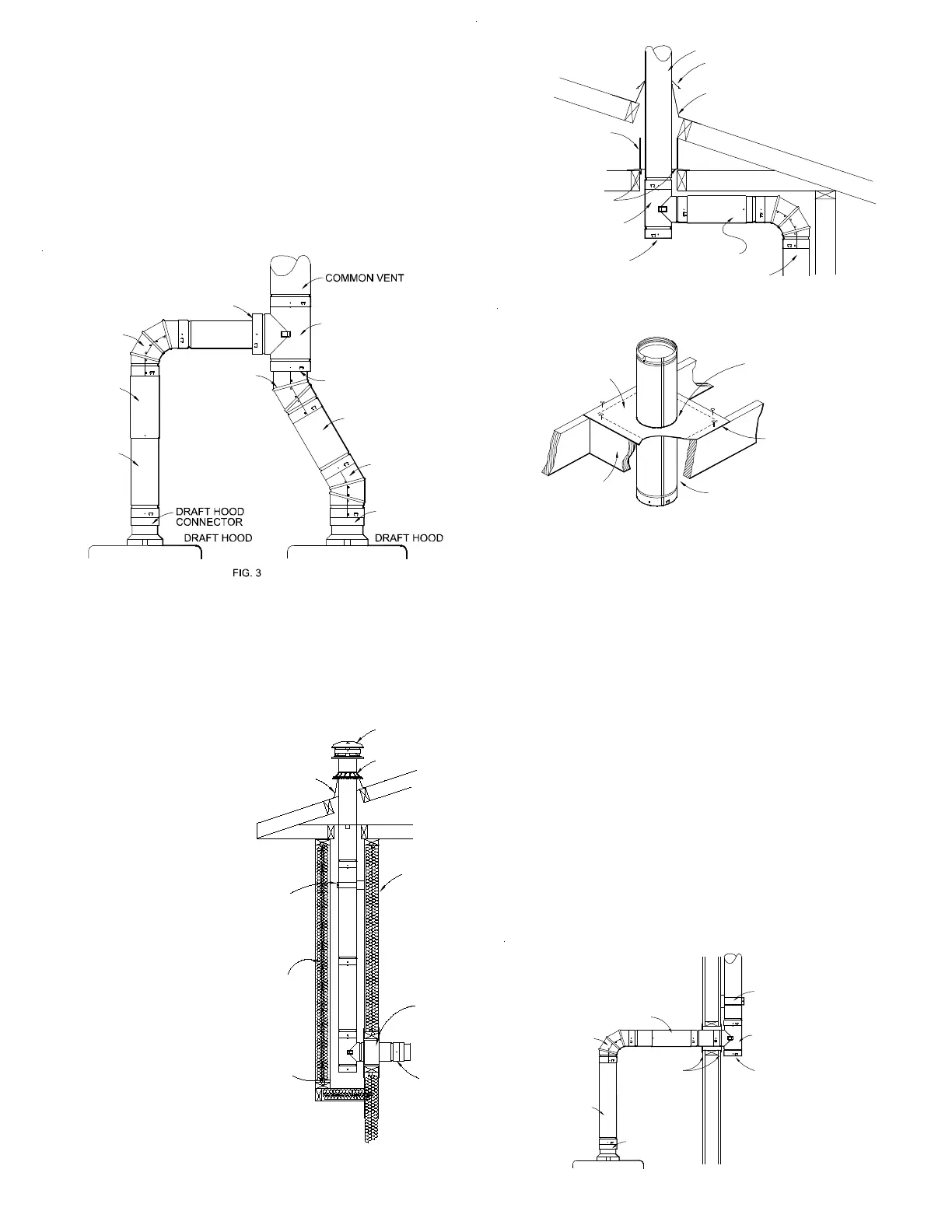

8. USE OF GAS VENT FITTINGS (See Figs. 3 & 7.)

Do not cut gas vent pipe or fittings. Adjustable lengths are telescoped over

fixed lengths, to accommodate odd distances between vent lengths or

connectors. An adjustable length suspended below a support serves as an

expansion joint between two fixed points of properly supported gas vent.

Ordinarily, the adjustable length must be secured, but for expansion joints it

should just maintain good contact and a minimum 1-1/2” overlap. DO NOT USE

adjustable lengths to suspend any weight of pipe below.

Model RV Elbows are fully adjustable.

Selkirk tees, elbows, increasers, and short lengths are specially designed to

facilitate interconnections.

Tees used to start vertical vents must use a tee cap to prevent air leakage. All

unused openings in a gas vent must be sealed to prevent loss of effective

vent action.

5. VENT CONNECTOR TYPE AND SIZE

Selkirk Gas Vent pipe meets all building code and safety standards for use as

gas appliance vent connectors. Correct selection of connector and vent size

is detailed in the Selkirk Gas Vent and Chimney Sizing Handbook, the Installation

Gas Code CSA-B149.1-00, the National Fuel Gas Code NFPA 54, and local/

regional codes.

Draft hood connectors must be attached to the appliance outlet with screws.

Single wall connectors, if used must be secured to the appliance, to the gas

vent, and at all joints with 3 sheet metal screws per joint. Attachment of vent to

non-metallic outlets should be per appliance manufacturer recommendations.

LENGTH

TYPE B VENT

TYPE B VENT

DRAFT HOOD

CONNECTOR

45/60° ELBOW

INCREASER

45/60° ELBOW

INCREASER

90° ELBOW

ADJUSTABLE

TEE

the Canadian Fuel Gas Code CSA-B149.1-00, the National Fuel Gas Code

NFPA 54, and/ or local building codes for air supply requirements.

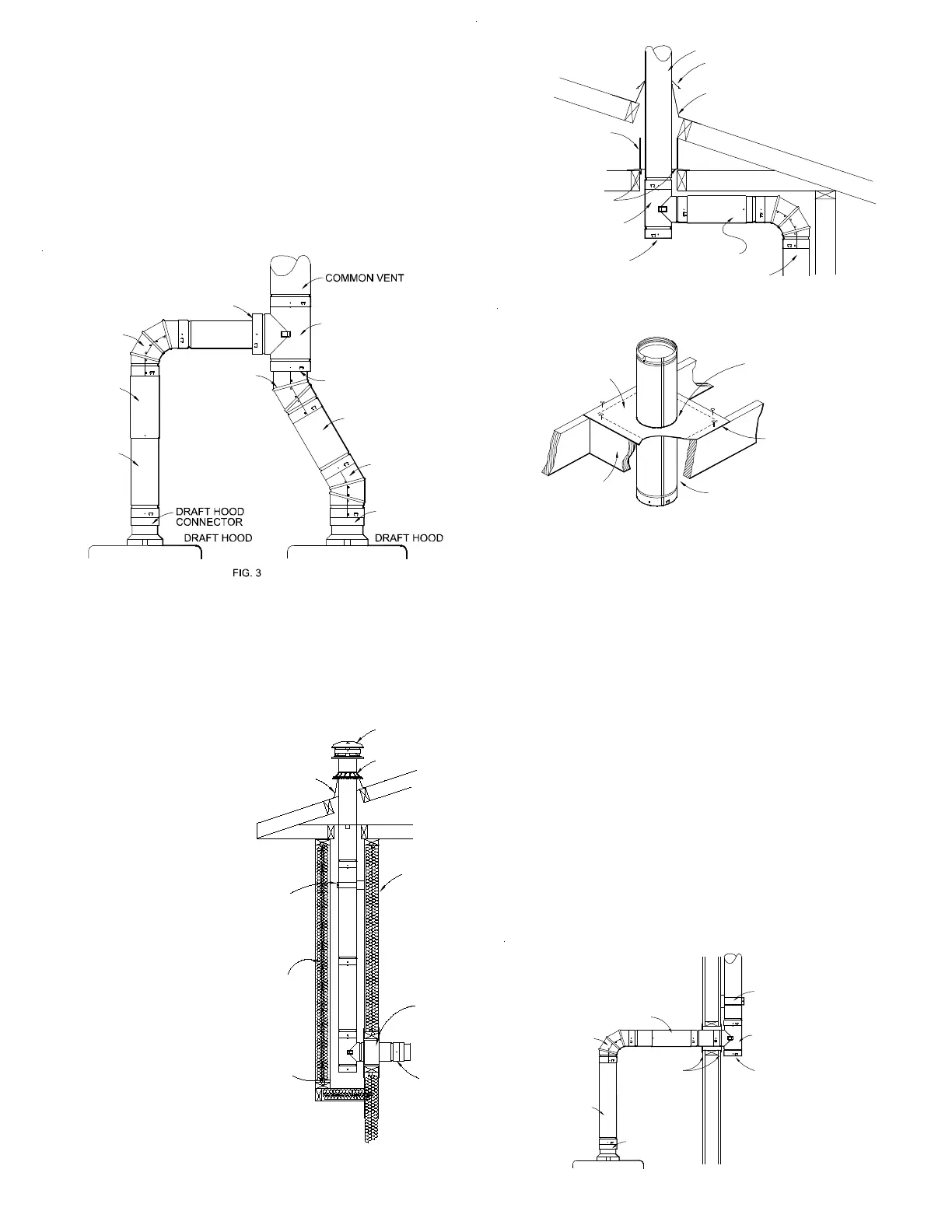

Enclose completely or use

metal shield (by others).

Maintain at least minimum

airspace clearance to

enclosure, wires, and

building insulation.

FIG. 5 - TYPICAL CEILING AND ROOF PENETRATIONS

Tee Cap

Firestop

Tee

Pipe

Adjustable

Length

Pipe

Adjustable

Flashing

(Attic)

Storm

Collar

Maintain minimum airspace

clearance to combustibles,

wires, and insulation.

1" - for 3" thru 24" sizes

2" - for 26" thru 48" sizes

at Walls, Ceiling, Roof, and

Penetrations.

FIG. 6

FIRE STOPPING REQUIRED FOR ALL

CEILING/FLOOR PENETRATIONS

Framing

required if

no floor

Maintain minimum airspace

clearance to combustibles,

wires, and insulation.

1" - for 3" thru 24" sizes

2" - for 26" thru 48" sizes

at Walls, Ceiling, Roof, and

Penetrations.

Gas Vent

Fire Stop placed

on top of floor or

framed opening.

Hole in any generic

firestop / support

plate to be nominal

pipe ID + 5/8". (Ex.-

hole for 4" vent to

be 4-5/8")

26 gauge galv.

steel Fire stop

Rain Cap

Storm Collar

Wall

Support/Band

R12 Max

Insulation

Enclosure

2” Clearance

Wall

Drafthood

Connector

Vented Flashing

Wall

Thimble

FIG. 4 - EXTERIOR

ENCLOSED WALL

PENETRATION FOR

TYPE B

Tee Cap

(Must be

used here)

LENGTH

ADJUSTABLE

90° ELBOW

TYPE B VENT

CONNECTOR

DRAFT HOOD

TEE

Wall Support/Band

Assembly For Sizes

3"-8". Support Plate

or Bucket for sizes

26"-48"

Pipe Collars or

Wall Thimbles for

3"-8" Supplied by

others for larger

sizes.

FIG. 7 - INTERIOR WALL PENETRATION FOR TYPE B

FIRESTOP SPACER

OR

WALL THIMBLE

Loading...

Loading...