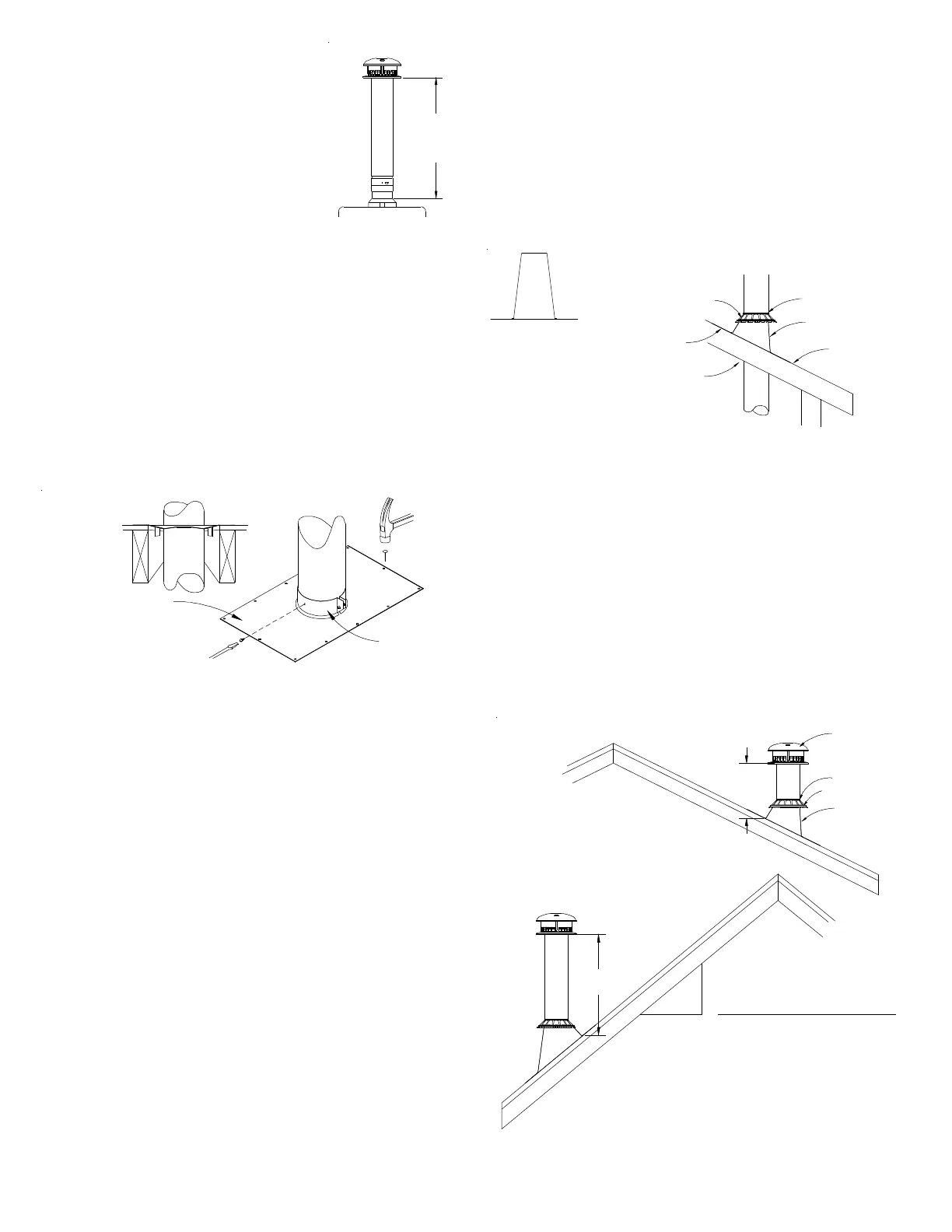

FIG. 9 FIRESTOP/SUPPORT ASSEMBLY

Plate support may be

trimmed or replaced

with custom size,

generic plate if

necessary, as long as

proper clearances are

established and

maintained.

CLAMPING

BAND

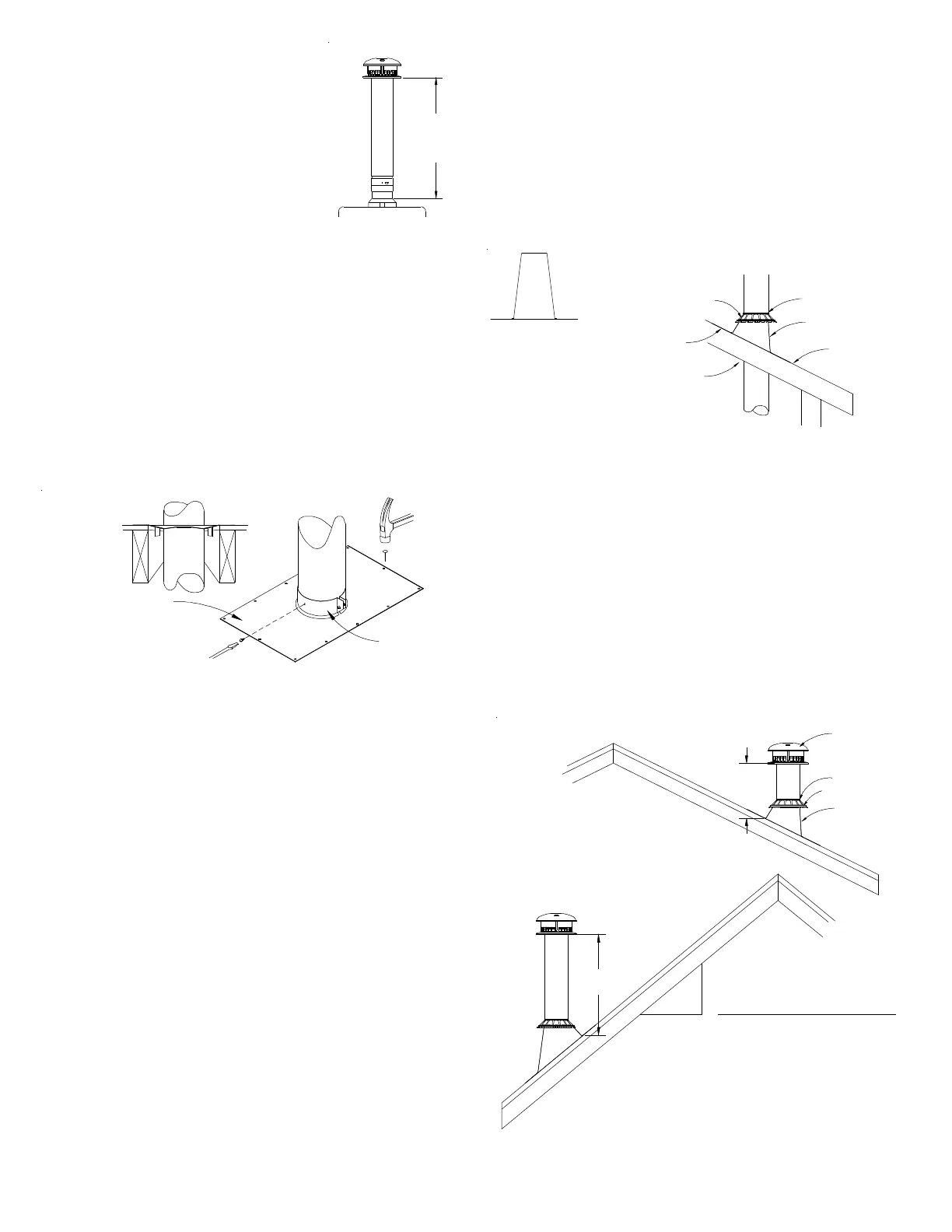

Top and sides of

flashing under roofing

Bottom of flashing

over roofing

Adjustable

Flashing (AF)

Apply Silicone

Sealant

Storm Collar (SC)

Maintain airspace

minimum clearance to

combustibles through roof.

1" - for 3" thru 24" sizes

2" - for 26" thru 48" sizes

FIG. 11-B

ELEMENTS FOR PROPER ROOF FLASHING INSTALLATION

FIG. 11-A

TALL CONE FLASHING

FOR FLAT ROOFS ONLY

Minimum Height

From Roof

To Lowest Discharge

Over 20/12 to 21/12

FIG. 12-B

LOCATION RULES FOR FLAT TO 21/12 PITCH

Height

above

roof

Roof Pitch is X/12

12

Over 10/12 to 11/12

Over 18/12 to 20/12

Over 16/12 to 18/12

Over 14/12 to 16/12

Over 12/12 to 14/12

Over 11/12 to 12/12

Over 9/12 to 10/12

Over 8/12 to 9/12

Over 7/12 to 8/12

Flat to 7/12

Roof Pitch

X

FIG. 12-A

FOR ROOF PITCH OF 7/12 OR LESS

8.0

3.25

6.0

7.5

7.0

5.0

4.0

Opening Ft.

1.5

2.5

2.0

1.0

Storm Collar (SC)

Adjustable

Flashing (AF)

Silicone Sealant

Round Top

12"

Minimum

distance to

roof

Insure 1” minimum airspace is established and maintained.

Should an offset be required use a CF roof support or a support plate to

support the vent above the offset. Offsets can be a maximum of 60 degrees

and may take place in the attic.

Plumbers strap may be used to support both horizontal and vertical piping. All

gas vents extending above the roof more than 5 feet must be securely guyed

or braced.

11. FLASHING

The roof opening should be located and sized such that the vent is vertical

and has the required air space clearance. The Tall Cone Flashing is for flat

roofs only. It is nailed in place through all four sides of the base flange. The

Adjustable Roof Flashing is positioned with the lower portion of the base

flange over roofing material and the upper portion of the base flange under

the roofing material. Nail through only the upper portion and sides of the base

flange. (DO NOT nail through lower flange.) Use nails with a neoprene washer,

or cover the nail heads with a silicone sealant. Finish roofing around the

flashing, covering the sides and upper areas of the flange with roofing

material. See Figures 10-A & B.

Rule II - Tops for gas vent sizes 14” and larger.

For installations other than covered by the table (Fig. 11-B), or closer than 8

feet to any vertical wall, the top shall be not less than 2 feet above the highest

point where the vent passes through the roof and at least 2 feet higher than

any portion of a building within 10 feet.

These rules were established on the basis of tests conducted in accordance

with American National Standard ANSI/UL 441.

12. VENT TERMINATION

Gas vent piping must extend through the flashing to a height above the roof

determined by Rules shown below. A storm collar is installed on the vent pipe

over the opening between pipe and flashing. Silicone sealant is used over the

joint between pipe and storm collar. Install a Selkirk Round Top to keep out rain

and snow.

If the gas vent extending more than 1.25m (4’) above the roof additional lateral

support is required such as a Selkirk Roof Brace Kit.

Rule 1:

The top is suitable for installation on listed gas vents terminating a sufficient

distance from the roof so that no discharge opening is less than 2 feet

horizontally from the roof surface, and the lowest discharge opening will be

no closer than the minimum height specified in Fig. 11-B. These minimum

heights may be used provided that the vent is not less than 8 feet from any

vertical wall.

9. MINIMUM GAS VENT HEIGHT

A minimum gas vent height of 5 feet above the

appliance draft hood is required. Where the vent

has an offset, or serves multiple appliances, greater

heights may be required for proper venting. Special

care must be taken with short gas vents on duct

furnaces, unit heaters, and furnaces in attics to

assure they have sufficient vent height to assure

complete venting. Refer to appliance manufacturer

instructions and local codes for required minimum

heights.

10. SUPPORT - PRIMARY AND OFFSETS

Gas vent piping must be securely supported.

Lateral runs are to be supported at least every 5

feet. The Support Plate has been tested to support a maximum of 10 m (35’)

of Gas Vent; if additional height is required, use another Support Plate on

another floor level. Vertical runs firestopped at 8 to 10 foot intervals need

only be supported near the bottom.

Cut away and frame a four sided opening in the floor from which the Gas

Vent shall be supported, to provide 25mm (1”) minimum clearance to

combustibles.

Nail Support Plate securely to joist and framing members using 4 x 1-1/2” long

nails (1 nail at each corner).

Insert the first length from above through the Band and the opening to achieve

the required amount of Gas Vent below the Support Plate. Secure clamping

band to the length with tabs and 1/4” screws (provided) so weight of vent

rests on plate. Room should be left for the draft hood connector and adjustable

length.

Additional Gas Vent Lengths above the Support are simply stacked on. See

joining section to secure lengths together.

Minumu

vertical

height

5 feet

FIG. 8 - MINIMUM

VERTICAL HEIGHT

10-A

10-B

11-A

11-B

Loading...

Loading...