LD1621INT Page 2

Accuracy

The development of a new material with a density

close to that of water and an enhanced quality of

surface finish results in a piston that glides easily

in the measuring chamber at very low flows. The

smallest leakage downstream of the meter can

therefore be registered.

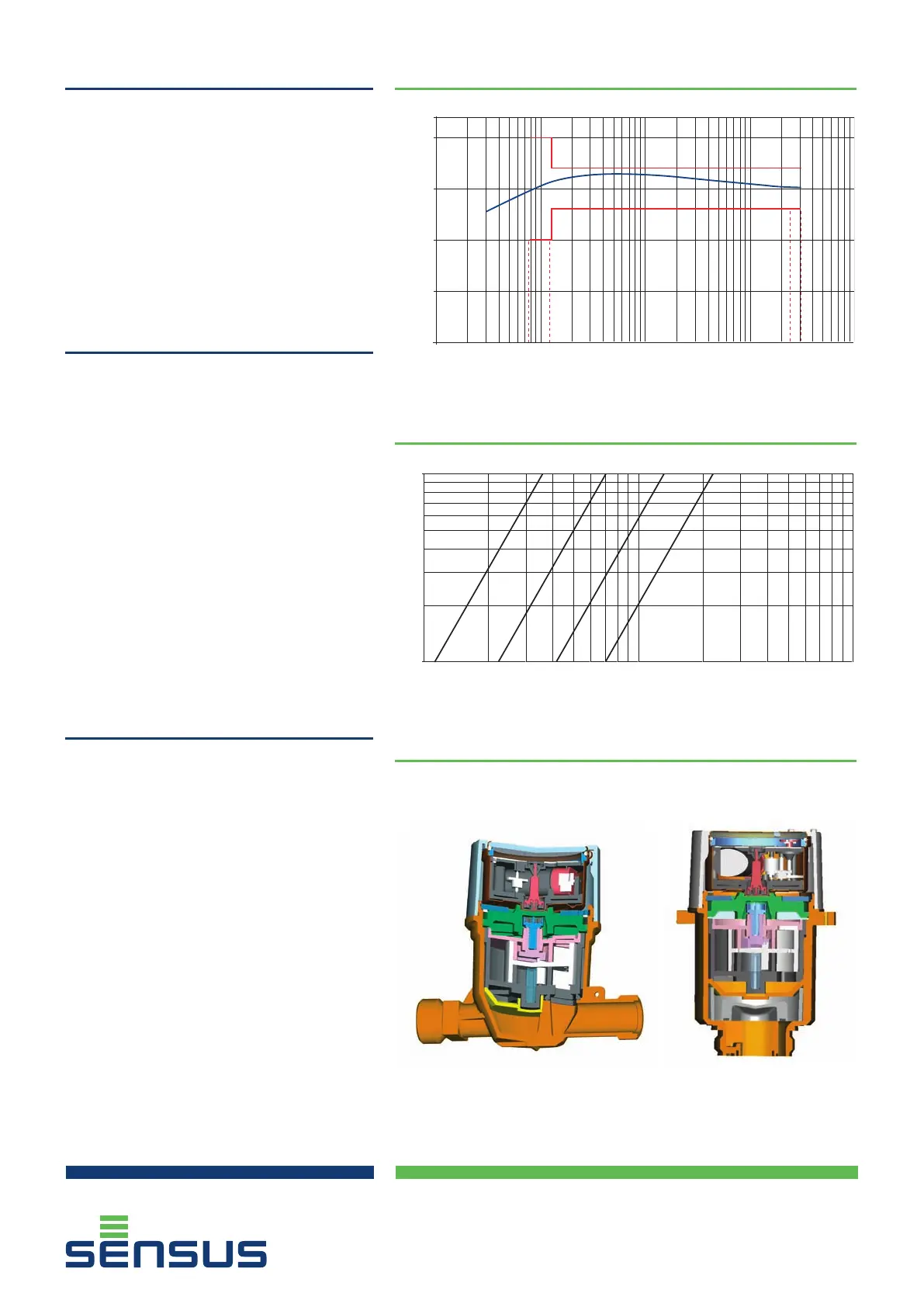

The measuring range of the 620 meter is much

wider than class C requirements. With the approval

according the new MID regulation a Q3/Q1 ratio up

to 400 can be obtained that combines the precision

at both small and high flowrates.

Reliability

The exclusive composite material of the piston

of the 620 meter combine lightness and excellent

surface conditions. The piston can move in the

measuring chamber without friction and also with

very low wear.

Foreign matter present in water can be filtered

first by the tubular strainer, then by the seat

strainer. The smallest particles can go through the

meter without damage; the elastic pivot enables

the particles to pass between the piston and the

measuring box. In this case, the surface hardness of

the piston and the measuring box avoids scratches.

All the gears are situated in the dry part of the

meter (totalizer), which removes any risk of

blockage due to suspended matter in the water.

The 620 water meter keeps its metrological

accuracy for many years of operation, even in very

difficult working conditions.

Register

The display of 8 drums (5 for m3, 3 for litres) and

1 pointer ensures perfect readability. The lowest

resolution is 0.05 litres. The dial has a central disc

whose rotation indicates the passage of water. This

indicator can be used to reveal a downstream leak.

The plastic register is equipped with a wiper for

optimum legibility under all conditions. The 620

water meter can operate in any position and its dry

dial can rotate up to 350º. The dial can therefore be

easily read under all conditions of use.

When meters are installed in a very humid

environment (external pit for example) the 620

meter(*) can be supplied with a metal/glass register

giving the guarantee of index readibility.

Typical Accuracy Curve

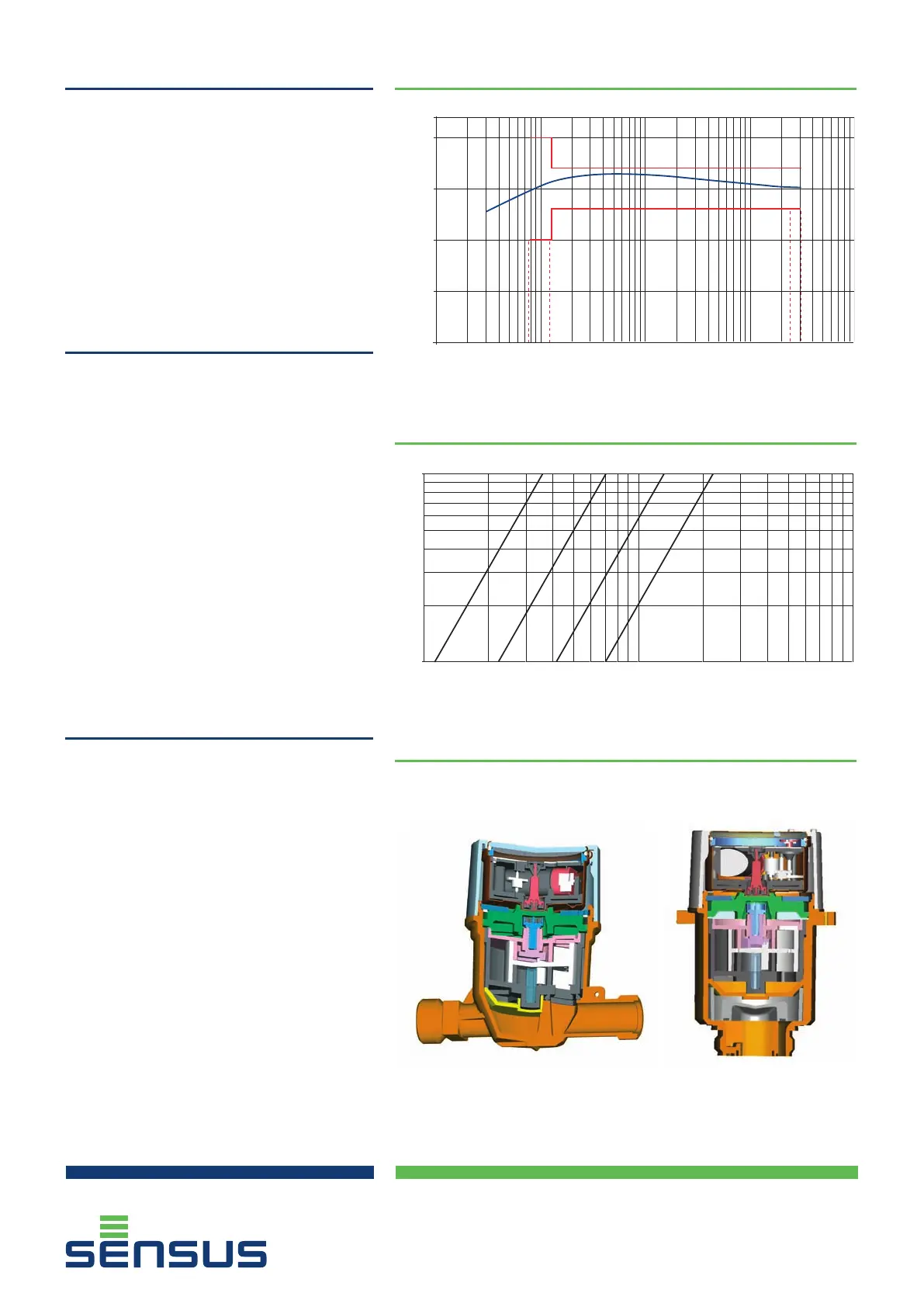

Typical Pressure Drop Curve

Cross Section

Q

1

Q

2

Flow Q

3

Q

4

-15%

-10%

-5%

0%

5%

Accuracy(%)

Q

3

/R

1.6 Q

1

1.25 Q

3

DN 15

DN 20

DN 25-30

DN 40

Head loss (bar)

1

3 5 7 10 20

100

Flow (m

3

/h)

0.1

1.0

In-line version

Co-axial version

Loading...

Loading...