Welding Nozzle

1. Welding nozzle using:

Too high temperature will weaken the welding nozzle function, so choose the temperature as low

as

possible.

The welding nozzle of restoring

force is

good,

even under the low temperature it can

also fully complete the welding work. Whar is more, it can

protect

temperature sensitive elements

2. Do not

use

welding nozzle,

When

do

not

use

welding nozzle, do not let welding nozzle in high temperature condition for long

time. Or

you

will make

the

flux of welding nozzle on change to oxide. which will make the heat

conduction of welding nozzle

weaker.

3. After use welding nozzle:

After the

use,

should wipe clean the welding nozzle and

plate

new tin layer on it to

prevent

the

welding nozzle

from

oxidation.

4. Elding nozzle maintain

Check and clean the

welding nozzle:

a. Connect

the

power

supply. wait for the temperature to stab llze.

b.After the temperature stabllity. clean the welding nozzle

with

cleaning sponge.

and check rt.

c. lf welding

nozzle

on

tin

part

contains black

oxide.

plate

a new tin layer on the welding nozzle,

then use

leaning

sponge

to wipe welding nozzle. So repettive operatron to Temove the oxide

and then

plate

a

new tin layer on the welding nozzle.

d. lf welding nozzle becomes deformation or serious

erosion.

must

replace the weldrng nozzle with

a

new

one

(Suggest

using

the o'iginal nozzle).

5. Welding nozzle cleaning:

Should

periodically

clean the weld nozzle with the cleaning sponge

(or

with a cleaning wet

cloth).

Because after welding, the residual slag will

produce

oxide and carbide

which

can

damage the welding nozzle or cause welding error or

make the heat

conduction of

welding

nozzle weaker. Long time continuously using

welding nozzle, once a week thewelding nozzle

should be taken apart to clean the

residual

slag

on the surface, so to

prevent

welding

nozzle

damaged and

reduce

temperature.

6. Extend

the

welding nozzle life,

a.

After

each

finish the welding work,

plate

a new tin layer on the welding nozzle to

prevent

welding nozzle from oxidatron and extend the using

life.

b. Under the condition of

normal working

please

set the temperature as low as

possible.

Low

temperature can reduce welding nozzle oxidation, as

well as can easily to weld components.

c. Only in necessary condition to use thin welding

nozzle,

because

of the thin welding nozzle less

durable than the coarse one.

d. Don't use welding nozzle as detection tools, because

weldrng nozzle bending will make coating

rupture and shorten its service life.

e. Use less active rosin flux, because the high content

of active rosin will accelerate welding nozzle

coating corrosion.

f.

When not using welding nozzle,

please

tum off it' s

power

as

far as

possible

to

prolong

its

service life.

g.

Don't butt

welding nozzle with

great

heavy stress, because that is

not

equal

to faster heat.

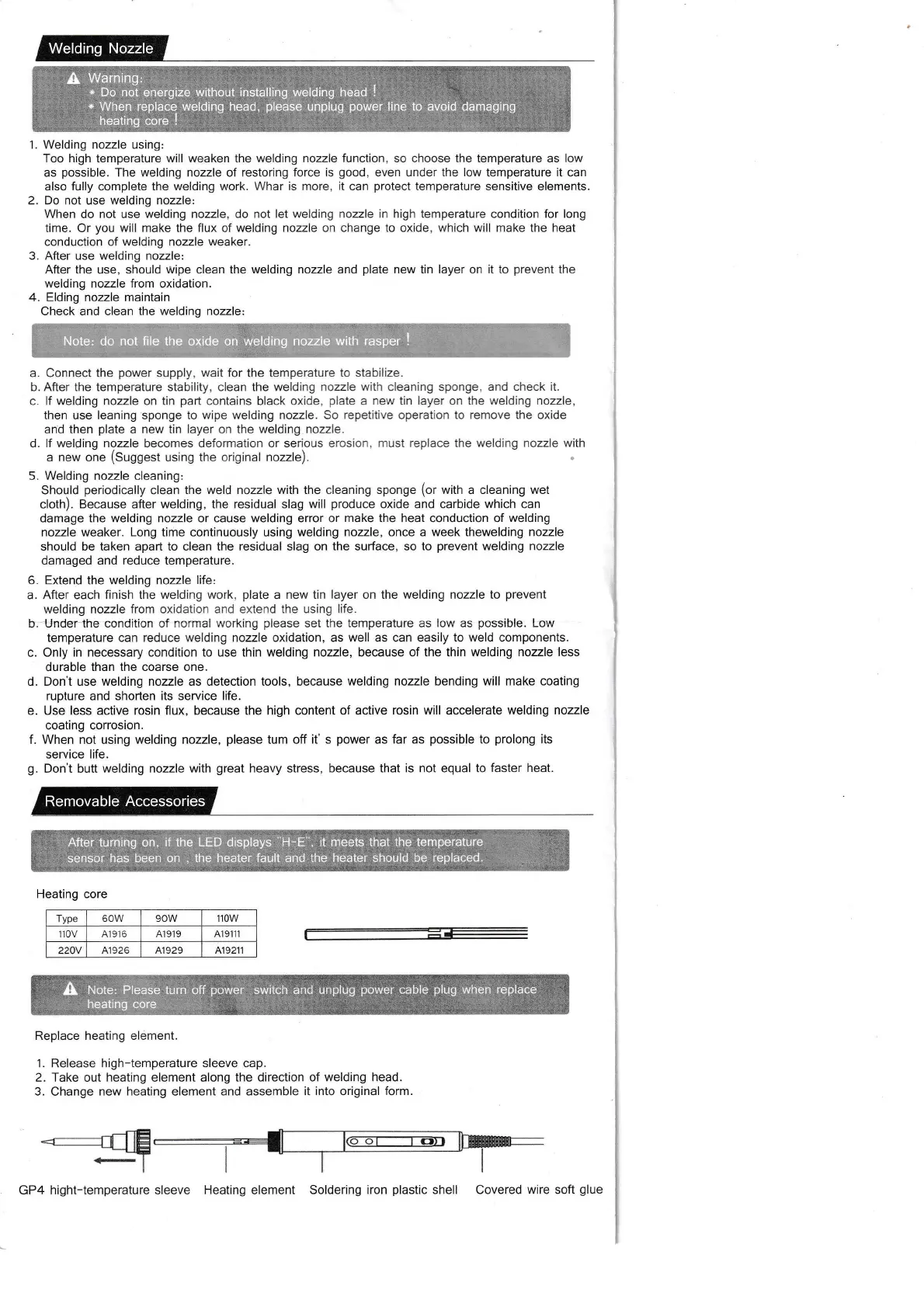

Heating core

Type

60w 90w 110W

r10v A1916 A19i9

419111

220V A1926 41929 A19211

Replace heating element.

'1.

Release

high-temperature sleeve cap.

2.

Take

out

heating

element along

the direction of

welding head.

3.

Change

new heating element and assemble

it into original form

Removable

Accessories

$,

Nore

cable.

heati

&x

p'ug

when

ng core

i

a

let,lu

K

GP4 hight-temperature sleeve

Heating

element

Soldering iron

plastic

shell Covered

wire

soft

glue

Note: do not

file

the oxide oii welding

nozzle with rasper !

Afteiturning

on, if the LED displays

;

iil,rleei5.

that

the

:teirperature

sensor htas been on .

lhe healdr fault:

and the:healer:shquld

be

replaced.

Please

power

Loading...

Loading...