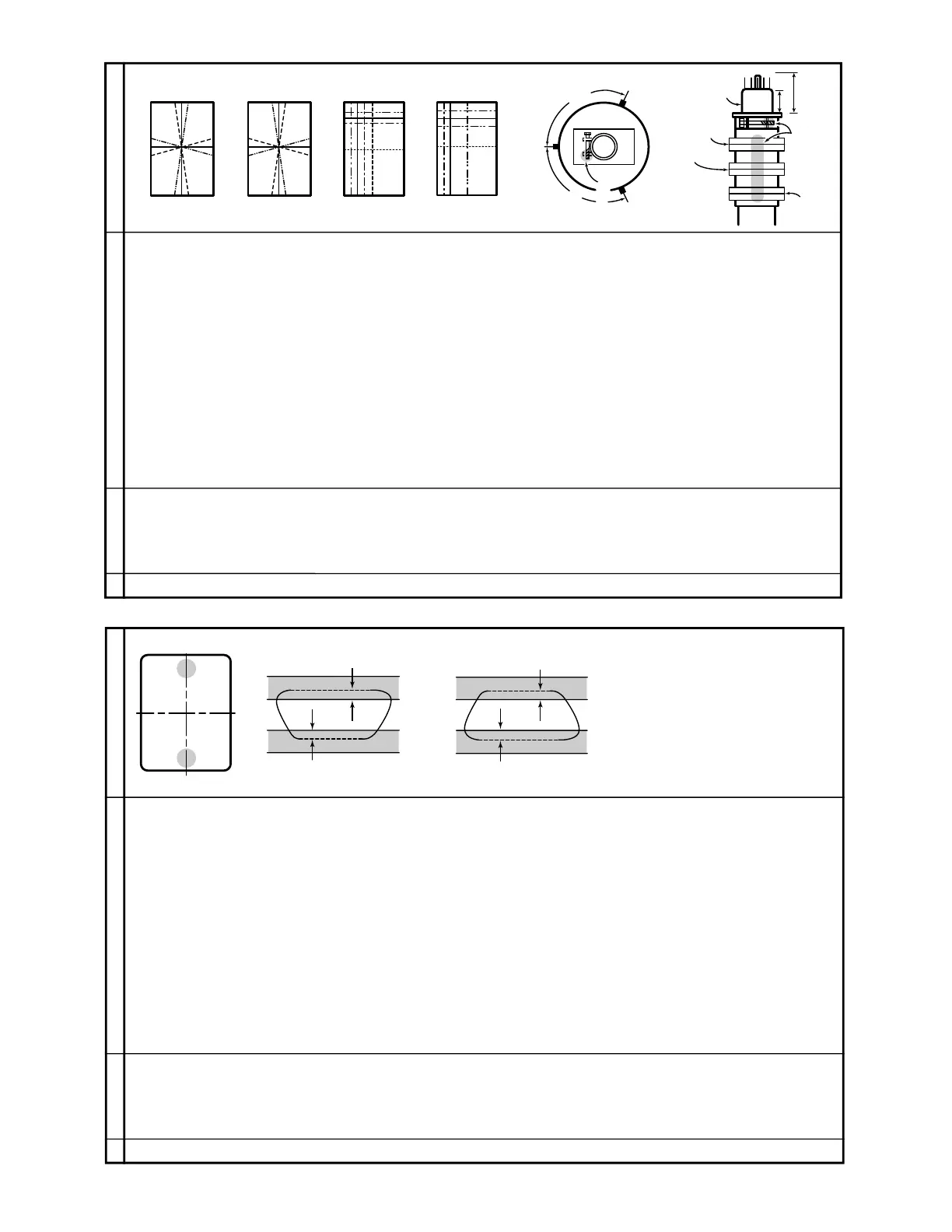

Fig. a

Fig. b

Fig. c

Fig. d

1. Receive the "Crosshatch Pattern" signal.

2. Using the remote controller, call NORMAL mode.

STATIC CONVERGENCE

1. Turn the 4-pole magnet to a proper opening an-

gle in order to superpose the blue and red col-

ours.

2. Turn the 6-pole magnet to a proper opening an-

gle in order to superpose the green colour over

the blue and red colours.

DYNAMIC CONVERGENCE

1. Adjust the convergence on the fringes of the

screen in the following steps.

a) Fig. a: Drive the wedge at point "a" and swing

the deflection coil upward.

b) Fig. b: Drive the wedge at points "b" and "c"

and swing the deflection coil downward.

c) Fig. c: Drive the "c" wedge deeper and swing

the deflection coil rightward.

d) Fig. d: Drive the "b" wedge deeper and swing

the deflection coil leftward.

2. Fix all the wedges on the CRT and apply glass

tape over them.

3. Apply lacquer to the deflection yoke lock screw,

magnet unit (purity, 4-pole, 6-pole magnets) and

magnet unit lock screw.

Finally received the Red-only and Blue-only sig-

nals to make sure there is no other colours on the

screen.

PURITY ADJUSTMENT

No.

Adjusment point

Conditions/Adjusting procedure Waveform or others

PURITY ADJ. 1. Receive the GREEN-ONLY signal. Adjust the

beam current to ~ 500 µA.

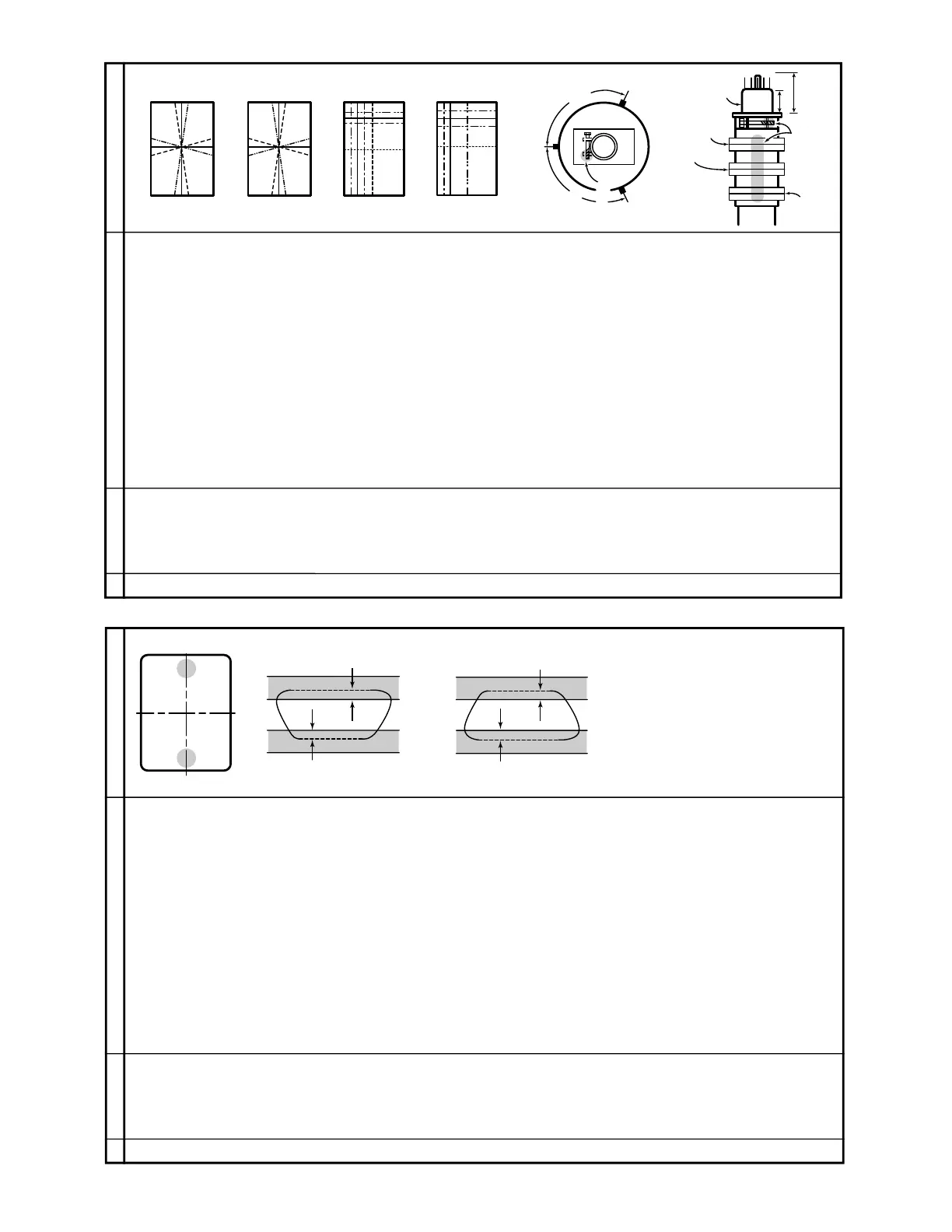

2. Maintain the purity magnet at the zero magnetic

field and keep the static convergence roughly

adjusted.

3. Observe the points a, b, as shown in Fig. 1-1

through the microscope. Adjust the landing to the

A rank requirements.

4. Orient the raster rotation to 0 eastward.

5. Tighten up the deflection coil screws.

» Tightening torque: 108 ± 20 N (11 ± 2 kgf)

6. Make sure the CRT corners landing meet the A

rank requirements. If not, stick the magnet sheet

to correct it.

Note: This adjustment must be done after

warming up the unit for 30 minutes or

longer with a beam current over 500

µ

A.

1

Loading...

Loading...