MD-MS200W/MD-MS200/MD-MS200H

– 8 –

REMOVING AND REINSTALLING THE MAIN PARTS

Remove the mechanism according to the disassembling meth-

ods 1 to 4. (See Page 7.)

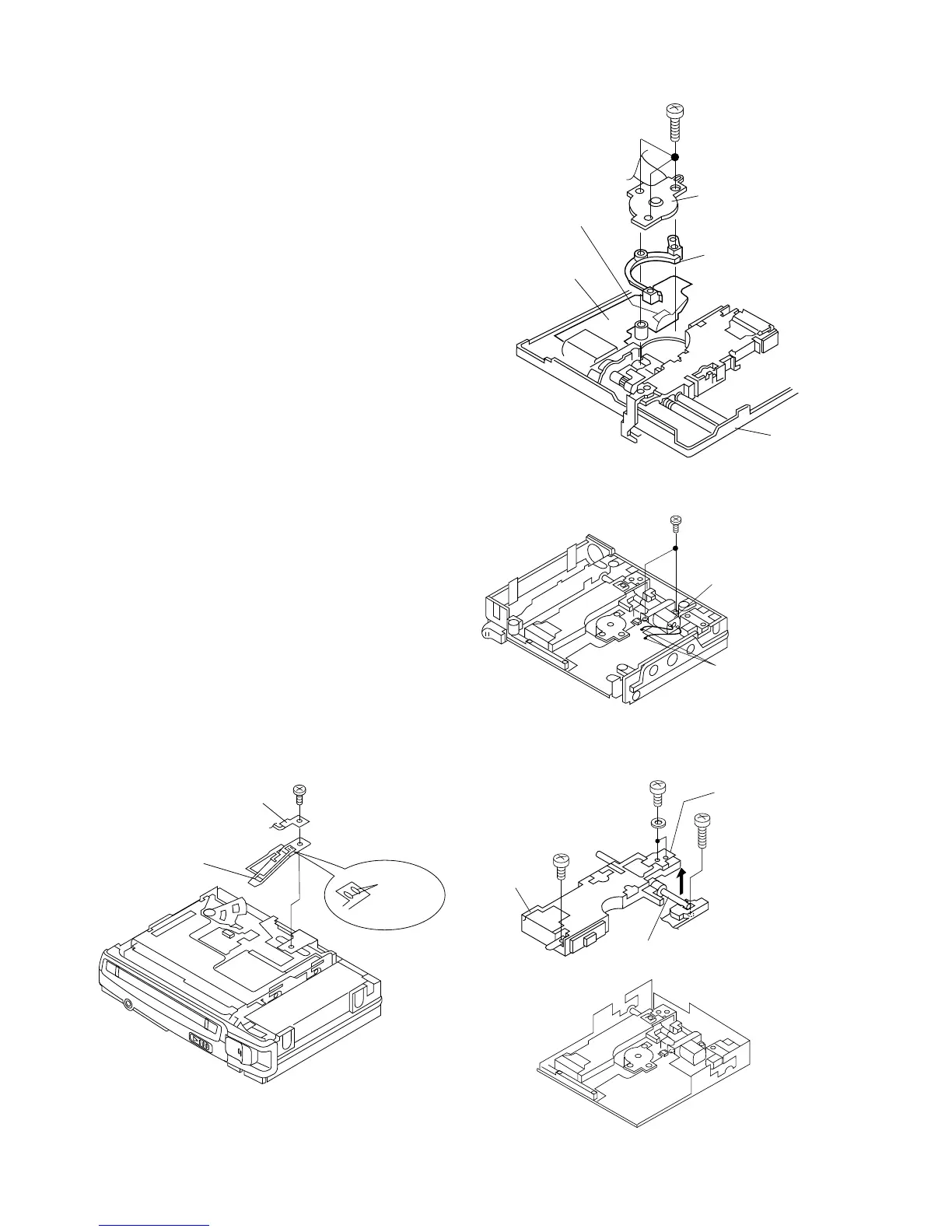

How to remove the disc motor (See Fig. 8-1.)

1. Remove the solder joint (A1) x 1 of flex PWB.

2. Remove the screws (A2) x 3 pcs. and remove the disc

motor.

Take care so that the turnrable is not damaged.

Figure 8-4

(A2) x 3

Ø1.4 x 4.5mm

Flexible PWB

solder joint

(A1) x1

Disc Motor

Motor Spacer

Mechanism PWB

Mechanism

Figure 8-1

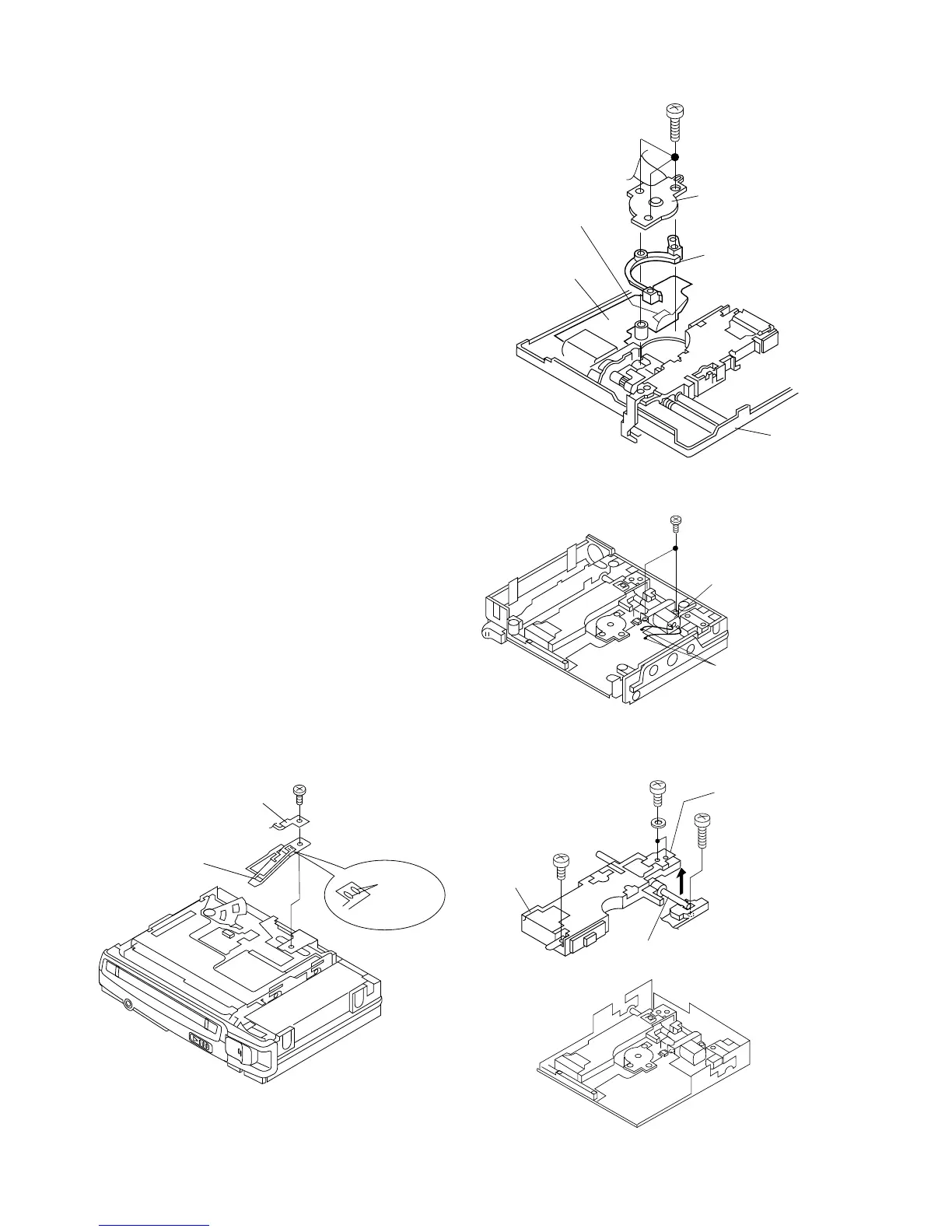

(B2) x2

Ø1.4x2.2mm

(B1) x2

Remove the solder joint.

Slide Motor

Figure 8-2

Figure 8-3

Shaft (C2) x 1

(C1) x 2

Ø1.4 x 3mm

(C1) x 1

Ø1.4 x 2.5mm

(C1) x 1

Ø2 x4.5mm

Pickup Unit

Magnetic field arm block

Magnetic head

Head intervening flexible PWB

(D1) x1

Ø1.4x2mm

Unsolder

(D2) x2

How to remove the slide motor (See Fig. 8-2.)

1. Remove the solder joint (B1) x 1 of slide motor lead wire.

2. Remove the screw (B2) x 1, and remove the slide motor.

Note:

Take care so that the motor gear is not damaged.

(If the gear is damaged, noise is raised in search mode.)

How to reinstall the optical pickup unit

(See Fig. 8-3.)

1. Remove the screws (C1) x 5 pcs.

2. Remove the magnetic fielt arm block from the pickup, and

move the magnetic field arm block outwards.

Note:

Take due care so that the magnetic head is not damaged.

3. Withdraw a little the slide motor side shaft (C2) x 1 pcs., and

slowly raise the optical pickup.

How to remove the magnetic head

(See Fig. 8-4.)

1. Remove the screw (D1) x 1 pc.

2. Remove the unsolder (D2) x 2 pcs. which connects the

magnetic head and the head hookup flex.

Note:

Mount carefully so as not to damage the magnetic head.

Loading...

Loading...